Single Enzymes uses in Bakery Products

What Are Single Enzymes’ Mechanisms and Applications in Bakery Products?

How are single enzymes used in bakery products?

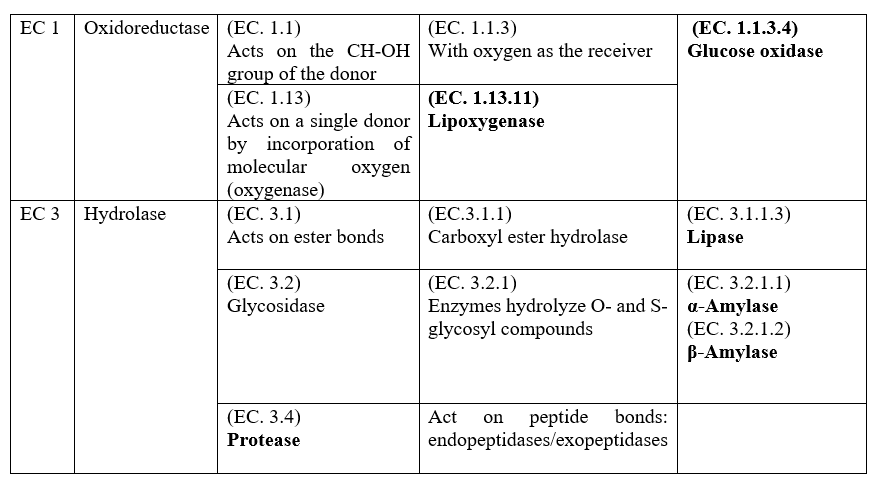

Enzymes can be added individually or in the form of complex mixtures in small quantities that act synergistically, antagonists, or additives during production. Supplementation of flour and dough with enzyme improvers is carried out to standardize flour for bread making. Application of enzymes in bread making is added during the mixing stage as a technological or processing aid with cereals as a raw material. Cereal components are used as substrates by enzymes to change biomolecules’ major and minor structures to achieve the desired functional properties. The type of substrate on which the enzyme reacts is used as the basis for classifying enzymes. Enzyme classification deals with the chemical structure and main characteristics of carbohydrates, proteins, and lipids, which are added to the description of enzymes. This is suitable with the International Union of Biochemistry and Molecular Biology (IUBMB), which recommends the name of enzymes in bakery products and the EC number, which can be seen in Table 1.

Table 1. EC number and recommended name of enzymes in bakery products by IUBMB

What types of enzymes are commonly used in bakery products?

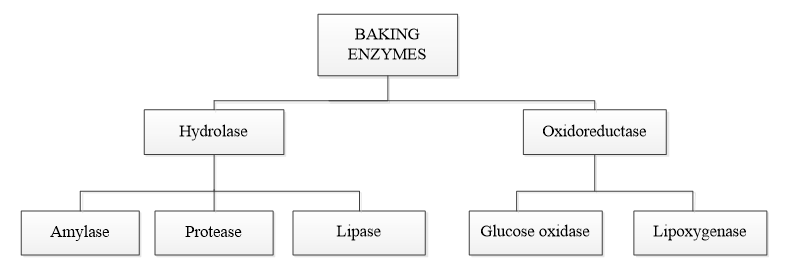

Enzymes usage in bakery products was considered characteristic, functionality, and classification, which will affect the quality of baking, including processing and final result of bakery products, especially texture. Classification and type of enzymes often used in bakery products can be seen in Figure 1.

Figure 1. Type of Enzymes Used in Bakery Product

What is amylase in bakery products and what is the mechanism and application in bakery products?

α- and β-amylase are enzymes naturally present in cereals. α-amylase is an endo-enzyme that catalyzes the breaking of amylose and amylopectin bonds inside several branches and linear fragments. These fragments are called dextrins. β-amylase is an exo-enzyme that produces maltose. Exoenzymes are enzymes released by cells that perform their duties outside of those cells, whereas endoenzymes are enzymes secreted by cells that perform their functions inside those cells.

The mechanism and properties of amylase determine the formation of starch structure in bread, recrystallization of amylopectin, bond formation of starch, and redistribution of water that occurs in the manufacture and storage of bread.

During bread storage, the gelatinized starch network gradually transforms into an amylopectin crystallites network. Along with the amylopectin retrogradation process, migration of water vapor occurs between crumb structures, and water is immobilized in amylopectin crystallites. This is a result of less flexible gluten connections, which increases crumb toughness and decreases resilience.

What is the protease and what is the mechanism and application in bakery products?

Proteolytic enzymes refer to proteases, proteinases, and peptidases that catalyse the hydrolysis of peptide bonds in proteins, which means that they can affect the physical properties of gluten. Proteases can be divided into 2 subclasses, endoprotease and exoprotease. Endoprotease hydrolyses peptide bonds in the inner protein of the polypeptide chain, resulting in ‘small peptides’ and even free amino acids. Exoprotease cut the ends of protein chains to produce free amino acids and sometimes small peptides.

The presence of proteases on the physical properties of have beneficial effects. Protease enzymes improve the volume and porosity of bread, minimize the need for kneading the dough, and use less energy during processing. During proteolysis, the enzymes break the connections between peptides (smaller protein fragments) and disassemble the globular structure of gluten. This modification explains why gluten becomes better at emulsifying during the hydrolysis process. The breakdown of peptide bonds facilitates the interaction between peptides and lipids, which enhances emulsifying properties of gluten. Thus, more peptide residues become available at the interface between oil and water. This causes a decrease in surface tension and increases emulsification activity. However, it is important to note that excessive proteolytic activity can lead to extensive degradation of gluten, which causes a decrease in the emulsifying capacity of the hydrolysates. Therefore the ability of gluten to form stable emulsions decreases.

What is lipase and what is the mechanism and application in bakery products?

Lipase is a lipolytic enzyme that facilitates the breakdown of ester carboxylic bonds and produces free fatty acids, diglycerides (DAG), monoglycerides (MAG) and glycerol. In baking, lipase was able to modify the dough properties through gluten and starch modification. Lipases improve dough handling properties. Improvement of the dough properties is characterized by increased dough stability, maximum resistance to stretching and hardness, and reducing the degree of softness and stickiness.

The way lipase works is by breaking down fatty acids in fats, making them more polar (water-loving) and increasing their ability to interact with other substances. This increase in surface activity is a functional effect of the lipase. When lipase breaks down fats, it produces substances like monoglycerides and diglycerides, which act as emulsifiers. These emulsifiers can form complex structures with amylose in flour. These complex inclusions with amylose contained in flour can increase the specific volume and toughness of bread, making it lighter and more chewy.

What is glucose oxidase and what is the mechanism and application in bakery products?

Glucose oxidase (GOX) oxidizes glucose into other substances. GOX also oxidizes water-soluble proteins (albumin and globulin). GOX makes the dough surface dry so it is easy to work with, improving formation and separation in the finished product. In addition, it impacts the rheological properties of the dough. It enhances dough stability, making it more resistant to stretching and reducing its extensibility. These changes can be observed in tests like farinograph, extensograph, and alveograph.

By adding GOX to the dough, it strengthens the structure of the dough, improves bread quality, and modifies gluten proteins.

What is lipoxygenase and what is the mechanism and application in bakery products?

Lipoxygenase (LOX) converts unsaturated fatty acids into peroxy radical fatty acids. This reaction requires oxygen. LOX catalyzes the peroxidation of unsaturated fatty acids. The production of H2O2 forms disulfide bonds in the protein gluten. The effect of LOX on gluten and dough is related to lipid oxidation by LOX, thereby triggering co-oxidation of SH groups in flour.

LOX increases dough resilience to overmixing and deformation, as well as characteristics that are influenced by moisture absorption. It is important to note that excessive amounts of LOX can negatively affect the optimal viscosity and characteristics of the dough. LOX affects the properties of the dough which affects dough stability and crumbs in bakery products (softer texture, elasticity, suitability for cutting) and brightens the product (baguettes, toast, sandwiches).

How to Optimize Usage of Single Enzymes in Bakery Product?

Single enzyme application as a food additive and processing aid can be optimized by considering the characteristics, mechanism of action, and understanding of enzyme regulation which are widely used in the bakery industry. Enzymes in the processing of bakery products have their respective roles according to the specific characteristics of the enzymes. The main role of enzymes in bakery products is to improve the functional and rheological properties of the dough according to the variation and type of bakery products, improve the quality and characteristics of bakery products such as volume, crumb texture, color, and taste, and extend shelf life (anti-staling). Optimization of the role and function of enzymes can be carried out by validating the concept of enzyme quality through baking tests including formulation development, process parameters (dough rheology, dough handling in the machine, temperature, and baking speed) as well as product appearance and sensory characteristics.

Baking test results can be utilized as a guide for performing research and development in an effective and efficient process phase, which also lessens trial and error in the production process. Continuous research and development is one way to explore the potential of food enzymes applied to bakery products.

Further research is required to promote continual improvement of the following factors:

- enzyme integration with other substances in the food matrix,

- parameters that affect how enzymes work in food systems

- efficacy of enzyme combinations to improve bakery products’ quality and

- understanding of regulations on enzyme usage as food additives and processing aid. Sustainability in food enzyme research would be able to offer references and information to develop safe and healthy bakery products for consumers.

Reference:

Rosell, C. M. and C. Collar. 2008. Effect of various enzymes on dough rheology and bread quality. In Recent Research Developments in Food Biotechnology. Enzymes as Additives or Processing Aids, 165–183. Kerala, India: Research Signpost.

Chandrasekaran, M. 2016. Enzymes in Food and Beverage Processing. CRC Press, USA.

Goesaert, H., Slade, L., Levine, H., and Delcour, J.A. 2009. Amylases and bread firming – an integrated view. Journal of Cereal Science, 50: 345–352.

Whitehurst, R.J. and van Oort, M. 2010. Enzymes in Food Technology, Second Edition. Blackwell Publishing Ltd, USA.

Hsu, P. Y., and Benfey, P. N. 2018. Small but mighty: functional peptides encoded by small ORFs in plants. Proteomics, 18: e1700038.

David, I. and Misca, C. 2012. The monitoring of enzyme activity of protease on the bread dough. Journal of Agroalimentary Processes and Technologies, 18 (3): 236-241.

Wang, P., Zou, M., Tian, M., Gu, Z., and Yang, R. 2018. The impact of heating on the unfolding and polymerization process of frozen-stored gluten. Food Hydrocolloids, 85: 195–203.

Salgado, C.A., dos Santos, C.I.A. and Vanetti, M.C.D. 2022. Microbial lipases: Propitious biocatalysts for the food industry. Food Bioscience, 45: 101509.

Colakoglu, A.S. and Ozkaya, H. 2012. Potential use of exogenous lipases for DATEM replacement to modify the rheological and thermal properties of wheat flour dough. Journal of Cereal Science, 55: 397-404.

Schaffarczyk, M., Østdal, H., and Koehler, P., 2014. Lipases in wheat breadmaking: Analysis and functional effects of lipid reaction products. J. Agric. Food Chem, 62: 8229-8237.

Monie, A., David, A., Clemens, K., Malet-Martino, M., Balayssac, S., Perez, E., Franceschi, S., Crepin, M., and Delample, M. 2020. Enzymatic hydrolysis of rapeseed oil with a non-GMO lipase: A strategy to substitute mono- and diglycerides of fatty acids and improve the softness of sponge cakes. LWT – Food Science and Technology.

Amiri, A., Shahedi, M., and Kadivar, M. 2016. Evaluation of physicochemical properties of gluten modified by Glucose oxidase and Xylanase. Journal of Cereal Science, 71: 37–42.

Popper, L. and Losche, K. 2021. Understanding Baking Enzymes. Robert Wenzel. Hamburg, Germany

Bonet, A., Rosell, C.M., Caballero, P.A., Gomez, M., Pe´rez-Munuera, I., and Lluch, M.A. 2006. Glucose oxidase effect on dough rheology and bread quality: A study from macroscopic to molecular level. Food Chemistry, 99: 408–415.

Pourmohammadi, K. and Abedi, E. 2021. Enzymatic modifications of gluten protein: Oxidative enzymes. Food Chemistry, 356: 129679.

Joye, I. J., Lagrain, B. and Delcour, J. A. 2009. Endogenous redox agents and enzymes that affect protein network formation during breadmaking: A review. Journal of Cereal Science, 50(1): 1–10.

Bahal, G., Sudha, M. L. and Ramasarma, P. R. 2013. Wheat germ lipoxygenase: Its effect on dough rheology, microstructure, and bread making quality. International Journal of Food Properties, 16(8): 1730–1739.