Combination Enzymes uses in Bakery Products

What Are Combination Enzymes Mechanisms and Applications in Bakery Products?

What are combination enzymes?

Enzymes usage in bakery products can be single or a combination of enzymes based on the final objective to be accomplished in bakery products. This is according to the type, action mechanism, and enzyme properties of ingredients and other components in the food system.

Why is the application of combination enzymes more effective than a single enzyme?

Combining enzymes can be advantageous for dough properties, processing, and bakery product characteristics. When enzymes work together in the food matrix during the production stage they can have a synergistic effect. Enzymes as processing aids are generally added to flour during the mixing process in bakery product production. When adding enzymes, it is important to consider their interactions with other enzymes, as well as their interactions with other ingredients and the conditions of the baking process. These interactions can have both antagonistic and synergistic effects on improving the quality of bakery products.

Synergism can be defined as a combination of specific materials usage that can result in actions and effects greater than the total effects of each component. This unique phenomenon is found in enzymes as a continuing aspect of enzymatic influences control and usage. The trend of enzyme development can be carried out by selecting and controlling a mixture of enzymes that can work synergistically and provide a better effect than single enzymes on different flour components. To achieve optimal results in bakery processing, it is important to have a comprehensive understanding of the process and select the appropriate combination of enzymes. It can produce a concept for the ideal product qualities at each level of processing, allowing optimization design of combination enzymes in stages. The stages of dough formation, fermentation, and baking are given priority for enzyme performance enhancement.

What is the secret to a successful combination enzyme application?

Enzyme performance can be improved at the molecular level to produce effectiveness and efficiency at each stage of the process. Integrated experimental design and optimization followed by chemical analysis, rheology experiments, and baking trials are required to provide solutions for more complicated problems.

Evaluation of enzyme combinations usage in bakery products will support experimental design, which is practicable using the following approaches:

Enzyme combinations application in bakery products:

- Testing the effects of using combinations of enzymes in bakery products to observe their impact on quality and processing stages like dough mixing, fermentation, and baking.

- Combinations mechanisms enzyme in improving bakery products quality, including processing (dough mixing, fermentation, baking), and sensory properties (texture, taste, color, and appearance)

- Optimization of enzyme combinations in bakery products: Fine-tuning the selection and proportions of enzyme combinations to achieve optimal results in bakery product quality and processing.

- Regulations on the use of US and EU food enzymes. A comprehensive approach in terms of application and regulation increases the awareness of researchers and formulators in food enzyme selection. This is related to the supply chain and distribution of food products that extend to various countries with different regulations, so it is necessary to guarantee product safety in all food categories.

What is the mechanism and application of combination enzymes in bakery products?

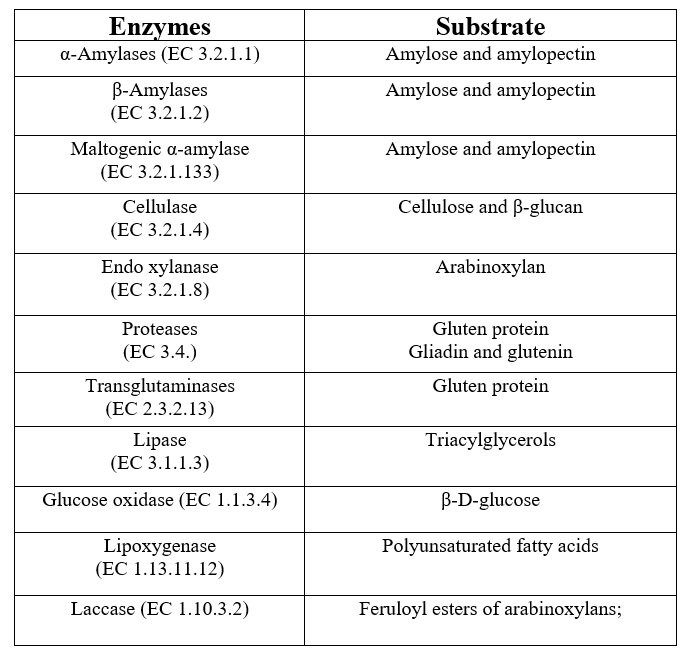

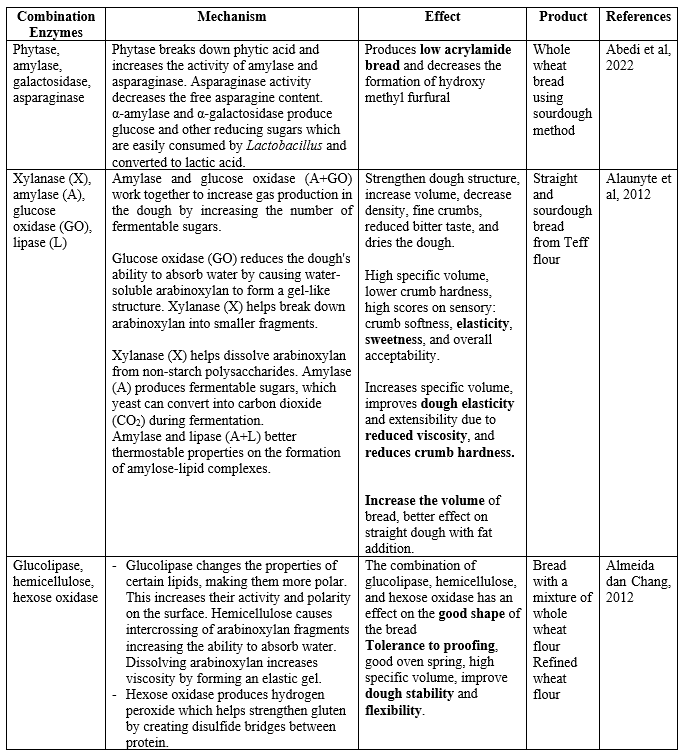

Mechanism combination enzymes are influenced by the role of each combined enzyme. Understanding the role of enzymes is needed to evaluate the early stages of the effect of integrated enzyme synergism in bakery products. Enzymes’ roles in food systems can be seen in Table 1, meanwhile, the application and mechanism of combinations of enzymes in bakery products can be seen in Table 2

Table 1. Enzymes’ Roles in Food System

Table 2. Application and Mechanism Combinations Enzymes in Bakery Products

How to optimize combination enzymes in bakery products?

Process and product quality parameters can be maintained by adding the right enzyme combination in terms of ratio, amount, type, and sequence of enzyme addition to other ingredients. This can increase the effectiveness of enzyme work, avoid excessive errors during the processing stages and reduce production costs.

Several considerations that need to be considered are

- several variables that affect processing

- interaction between variables in the food matrix

- validation and verification of the variables involved to determine critical variables. Response Surface Method (RSM) is the most effective and efficient optimization model in response to these considerations. The use of RSM in optimizing enzyme combinations and processing processes in the bakery industry can assist decision-making by understanding and describing processes through quantitative relationships between input and output variables.

What are the regulations on food enzyme usage in US and EU?

Food enzyme usage considers the purpose of enzyme application as a processing aid or food additive. The general definition of enzymes as processing aids and food additives has not been officially established. There are differences in determining the regulation of food enzymes between the European Union (EU) and the United States (US). EU separates the regulation between food enzymes and food additives, while US considers food enzymes to be a subgroup of food additives. The determination of regulatory uniformity must ensure the continuity of healthy and safe food production and consumption. The assessment to determine GRAS (Generally Recognized as Safe) status was issued by the FDA (Food and Drug Administration), US while the QPS (Qualified Presumption of Safety) status was issued by EFSA (European Food Safety and Authority), EU.

Regulations to ensure the safe handling of food enzymes can be seen in the FIAP (Food Improvement Agent Package). FIAP aims to achieve uniformity of European legislation on additives, including the approval of uniformity procedures (EC 1331/2008). The procedural authority to regulate and update the community register for food additives, food enzymes, and food flavoring is formulated in regulation (EC) no 1331/2008 to ensure the health and welfare of consumers. Regulatory specific framework (EC) 1332/2008 for food enzymes, EC 1333/2008 for food additives, and EC 1334 for food flavoring. Efforts to meet the needs and ensure comprehensive consumer protection are carried out through specific procedures in enzyme evaluation determined by FIAP.

EU defines food enzymes as products obtained from plants, animals, or microorganisms or products thereof including products obtained from fermentation using microorganisms which:

(i) contain one or more enzymes capable of catalyzing specific biochemical reactions.

(ii) which are added to food for technology during the production, process, preparation, treatment, packaging, transportation and storage of food.

EFSA records information on product safety that is utilized for assessment in the Guidance on the Submission of a Dossier on Food Enzymes for Safety Evaluation. Regulation (EC) No 1332/2008 states that food enzymes complying with the QPS are subject to general labeling obligations concerning traceability and labeling of genetically modified organisms (GMOs), traceability, and food products produced from genetically modified organisms. Food enzymes must be identified on the label with their exact name, followed by information about how they are used in food technology. Labeling must be easily visible, clearly legible, and not easily erased.

References

Miguel, A.S.M., da Costa F.E.V, Martins-Meyer, T.S and Dellamora-Ortiz, G.M. 2013. Enzymes in Bakery: Current and Future Trends. In Food Industry. Muzzalo, I (ed.). Intech, 287-321.

Di Cagnoa, R., De Angelis, M., Corsettic, A., Lavermicoccab, P., Arnaultd, P., Tossutd, P., Galloa, G., and Gobbettia, M. 2003. Interactions between sourdough lactic acid bacteria and exogenous enzymes: effects on the microbial kinetics of acidification and dough textural properties. Food Microbiology, 20: 67–75.

Almeida, E.L. and Chang, Y.K. 2012. Effect of the addition of enzymes on the quality of frozen pre-baked French bread substituted with whole wheat flour. LWT – Food Science and Technology, 49: 64-72.

Abedi, E., Pourmohammadi, K. and Sayadi, M. 2022. Synergic effect of phytase, amylase, galactosidase, and asparaginase activity on the mitigation of acrylamide and hydroxymethylfurfural in roll bread by co-culture fermentation. Journal of Food Composition and Analysis, 106: 104355.

Alaunyte, I., Valentina, S., Plunkett, A., Ainsworth, P. and Derbyshire, E. 2012. Improving the quality of nutrient-rich Teff (Eragrostis tef) breads by combination of enzymes in straight dough and sourdough breadmaking. Journal of Cereal Science, 55: 22-30.

Almeida, E.L. and Chang, Y.K. 2012. Effect of the addition of enzymes on the quality of frozen pre-baked French bread substituted with whole wheat flour. LWT – Food Science and Technology, 49: 64-72.

Kocabas, D.S. and Grumet, R. 2019. Evolving regulatory policies regarding food enzymes produced by recombinant microorganisms. GM Crops & Food, 10: 191–207.

Popper, L. and Losche, K. 2021. Understanding Baking Enzymes. Robert Wenzel. Hamburg, Germany