Vegetable oils Packaging

This post is also available in:

This post is also available in:

![]() Español (Spanish)

Español (Spanish) ![]() Ελληνικά (Greek)

Ελληνικά (Greek) ![]() Português (Portuguese (Brazil))

Português (Portuguese (Brazil))

Edible Vegetable Oils Packaging

Vegetable oils are obtained from a wide range of seeds, fruits, nuts, and grains, and the most popularly used ones are:

- Olive oil

- Sunflower oil

- Canola oil

- Soybean oil

- Palm oil

- Coconut oil

- Corn oil

- Mustard oil

- Peanut oil

- Safflower oil

- Cottonseed oil

The global production of vegetable oils in 2021/22 was 208.8 million metric tons. The top producers were Indonesia (52 million tons), Malaysia (22.4 million tons), China (18.6 million tons), India (14.3 million tons), the United States (13.5 million tons)

Global demand for edible oils is projected to increase by 2% from 2021 to 2026, reaching 87 million metric tons. India is the leading consumer of edible oils, with a demand of 13.7 million metric tons. China, the US, and Brazil are the next three largest consumers.

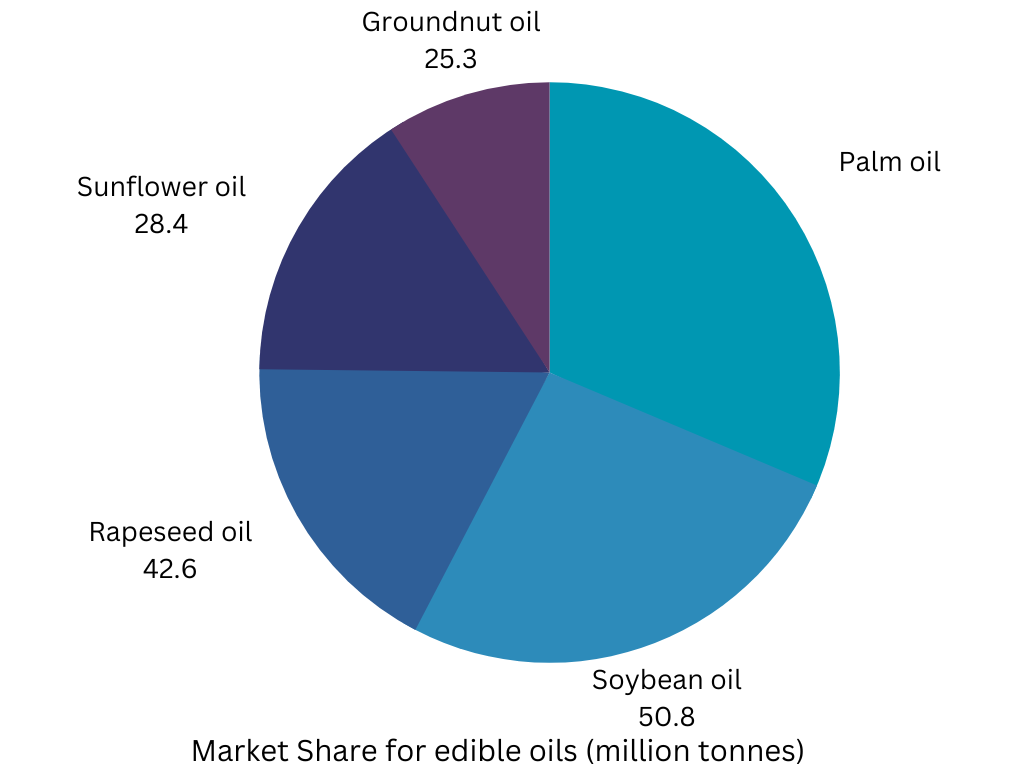

The most consumed edible oils in the world are presented below:

What criteria should be considered to choose the right packaging for edible oils?

The choice of packaging material for edible oils has a significant impact on the product’s quality, freshness, and shelf life. The appropriate packaging must have the following characteristics:

- Prevent the loss of flavor or acidity,

- Prevent the light transmission as it results in oil turning rancid. The light that may penetrate the packaging functions as an energy source, triggering the oxidation process.

- Prevent oxygen and moisture transmission.

- Prevent the oxidation of the oil, which will result in loss of flavor,

- Prevent the absorption of odors.

- Prevent the migration of substances from the packaging material into the oil (e.g., microplastics, etc.)

The material’s advantages and disadvantages should be carefully considered based on factors such as the type of oil, packaging size, transportation, and consumer preferences.

Here are some of the materials used for edible oil packaging, along with their advantages, disadvantages, and impacts on quality:

Glass

Glass bottles provide very good protection in the quality of the oil. They also provide an excellent barrier against light, oxygen, and moisture. The material does not interact with the oil, and it helps to preserve the flavor and quality. Additionally, they are reusable and recyclable. However, most of the time, it is not preferred as it is fragile and heavy, making transportation more costly. Glass bottles are mainly used for virgin olive oils not only for marketing reasons but also because they slow down the autoxidation rate by preventing the permeation of oxygen molecules into the bottle. An important factor is the color of the glass, as transparent glasses lead to photooxidation of the oil and shelf-life reduction.

Plastic

Regarding plastic bottles and containers, there are different advantages and disadvantages depending on the selected material. In general, plastic bottles are lightweight, shatter-resistant, and have a low production cost. They can be designed in different shapes and sizes and are recyclable. The main disadvantage is that some plastics may have oxygen permeability, leading to oil oxidation over time. Sometimes, they may require additional layers or coatings to enhance barrier properties. They do not provide as long a shelf life as tinplate containers, so they can be used where a very long shelf life is not required.

More specifically, the most frequently used containers are made of HDPE (High-Density Polyethylene), PET (Polyethylene Terephthalate), and PVC (Poly Vinyl Chloride). These containers provide a moderately long shelf life, are lightweight, and are easy to transfer.

Polyethylene Terephthalate Bottles (PET) provide a good barrier to odors and oxygen, and they have good clarity. HDPE bottles are used as packaging material due to their strength, hardness, and excellent resistance to chemicals. PVC is a widely used packaging material for edible oils in numerous countries. This popularity is primarily attributed to its transparency, versatility in accommodating various closures, compatibility with current packaging processes, and the possibility of incorporating personalized design elements. As with most transparent materials, PVC increases light exposure, enhancing oxidation. A solution to this is to add UV absorbers to the plastic materials to reduce their light transmission.

Due to issues related to the protection of the environment, PET has been gradually replacing PVC in the edible oil market.

Flexible Plastic Pouches are made from laminated or multi-layered films of different compositions. Τhey are lightweight and space-efficient for storage. As they can be designed with various sizes and shapes. The main advantage is that they are cost-effective for large quantities. It is important to note that there are some barriers used depending on the type of plastic as some plastics may allow oxygen and light penetration.

Metal

Tinplate Cans are commonly and widely used for edible oil packaging because of their many advantages. They provide excellent protection against light and oxygen, water vapor, and microorganisms. They are durable and tamper-resistant. It is an excellent choice where a very long shelf life is required. However, if the coating is compromised, tinplate cans might be prone to corrosion. This is why the inner part of the container is protected with lacquers (specific food-approved enamels). Typically, they can be found in different capacities, from 250g to 15kg.

The quality of oil stored in fresh containers can remain consistent for up to a year. Nevertheless, using containers multiple times leads to higher levels of corrosion in the tin coating. The exposed steel base reacts easily with the oil’s free fatty acids, resulting in oxidative rancidity and the formation of toxic organic tin salts. Aluminum is also utilized for edible oil packaging due to its lightweight nature and strong resistance to corrosion.

Overall, it is important to take into account that:

- Packaging materials that provide a strong barrier against oxygen, light, and moisture help maintain the oil’s quality and extend its shelf life.

- Transparent packaging materials should include UV protection to prevent light-induced oil degradation.

- Metal packaging should have appropriate linings to prevent reactions between the metal and the oil.

- Properly sealed packaging prevents air exposure and minimizes the risk of oxidation.

References:

M.S Tawfik, A Huyghebaert, Interaction of packaging materials and vegetable oils: oil stability, Food Chemistry, Volume 64, Issue 4, 1999, Pages 451-459, ISSN 0308-8146, https://doi.org/10.1016/S0308-8146(97)00202-1.

Indian Centre for Plastic in the Environment, http://icpe.in/icpefoodnpackaging/pdfs/9_edible.pdf

Food Packaging and Shelf Life – a Practical Guide’, Luciano Piergiovanni and Sara Limbo, Department of Food Science and Microbiology, University of Milan, Italy https://www.ofimagazine.com/content-images/news/Packaging.pdf