Agroecological Water Filter: A technology to make water drinkable and safe for human consumption

The lack of drinkable water puts more and more lives at risk

On UN News/Global perspective Human, the UN General Assembly President, during opening the high-level meeting on ensuring water and sanitation are available to all, said: “Access to water is not just about “liquid in a bottle” but instead touches on universal issues such as dignity, opportunity, and equality. Billions without clean water and sanitation a moral failure“. (news.un.org/en/story/2021/03/1087682 on UN News)

The World Meteorological Organization (WMO) states that the damage caused by the degradation of the environment is leading to an annual decrease in the level of drinking water available on the planet. According to this UN entity, in the last twenty years, the volume has been falling by one centimeter per year, both in surface and underground reservoirs. The WMO recalls that only 0.5% of all the water on the planet can be used for human consumption.

The Head of the agency highlighted worsening food insecurity and its impacts on human well-being. (news.un.org/pt/story/2021/11/1768982 on UN News).

A new technology to make water drinkable and safe for human consumption

Although there are several ways to treat raw water to make it potable, poor and/or distant communities generally do not have sufficient financial resources to install water treatment equipment and processes in their territories.

It is known that children are the main victims of diseases caused by contaminated water.

It is also known that the main diseases caused by contaminated water are: amebiasis, giardiasis, gastroenteritis, typhoid and paratyphoid fever, infectious hepatitis (Hepatitis A and E), and cholera. Indirectly, contaminated water is also linked to the transmission of worms, such as schistosomiasis, ascariasis, taeniasis, oxyuriasis, and hookworm.

The Agroecological Water Filter, or Slow Sand Filter, is a sustainable socioenvironmental technology* suitable, cheap, and easily accessible to all communities worldwide. It is built from simple and cheap materials (sand, pebble, charcoal) and is highly efficient in treating the waters of natural springs.

*(Economically viable. Ecologically correct. Socially fair. Culturally adequate. Technologically appropriate. Scientifically proven).

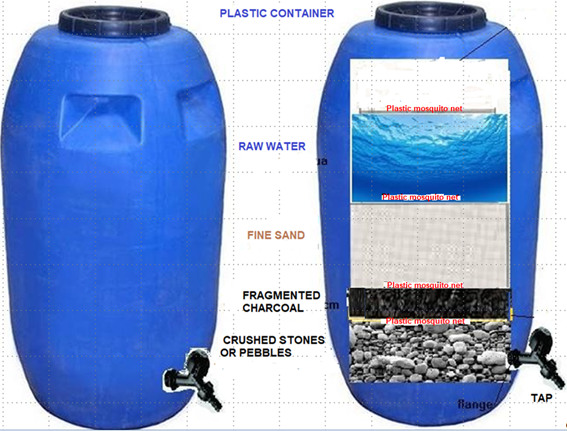

Materials utilized: Plastic container; Fine sand; crushed stone or pebbles; fragmented charcoal; Plastic mosquito net.

How the Agroecological Water Filter Works?

The Agroecological Filter works by using the action of gravity to cause water to descend naturally, passing slowly through the overlapping layers of sand, charcoal, and crushed stones or pebbles. Thus, the largest dissolved solid particles are retained in the first centimeters of the sand layer and are going to form an organic sludge full of biophagous microorganisms named “biofilm.”

Concomitantly, the smaller particles also dissolved, inclusive of the coliforms, are digested by these microscopic biophagous organisms of the biofilm, which stick and reproduce naturally on the layers of the organic sludge.

Both the charcoal and the crushed stone/pebbles play an important role in this process. The charcoal retains several chemical elements, and the pebbles leave fresh water.

How to mount:

1-First step. Cleaning components.

This step starts with the careful cleaning and disinfection of the components. The ideal is to wash the materials with a bleach solution (1 spoonful of bleach to each liter of water). After washing, dry all in the sun until the materials are completely dry.

(It is strictly forbidden to use a plastic container that was used to transport chemical products, fuels, ink, dye, or any other product that poses a risk to human and animal health. It is recommended to use a plastic container used to transport uncontaminated human food).

2-Second step. Overlapped components layers.

The design of a referential ruler for marking the overlapped layers of the components becomes necessary, and maybe even a broomstick. Thus, markings are done, with the dimensions of the layers, to warrant an increased accuracy when filling the filter with each component.

The ruler would stay, then, with the following markings:

- With 40 cm for the layer of fine sand;

- With 10 cm for the layer of fragmented charcoal;

- With 20 cm for the layer of crushed stone/pebbles.

3-Third step. Understanding the mounting.

3.1- Place 20 cm of clean pebbles inside the container.

Shake or tap lightly around the container to settle the pebbles;

3.2- Cut and place 3 discs of the plastic mosquito net over the pebble layer;

3.3- Place 10 cm of clean fragmented charcoal** over the pebble screens;

Again, shake or tap lightly around the container to settle the charcoal;

3.4- Cut and place 3 discs of the plastic mosquito net now over the charcoal layer

3.5- Place 40 cm of sand over the fragmented charcoal screens.

Again, shake or tap lightly around the container to settle the sand.

3.6- Cut and place 3 discs of the plastic mosquito net now over the surface of the sand.

3.7- Gently pour the raw water to be filtered over the sand screens until the useful volume of the container is full;

Once again, cut and place 3 discs of the plastic mosquito net but now over the surface of the raw water.

Recommendations:

**The charcoal fragments should resemble cubes measuring 5 to 10 mm. The presence of coal dust and fragments smaller than 5 mm must be avoided.

It is recommended to sift the charcoal through sieves with a mesh size of approximately 5 mm.

Before placing the filtering elements (sand, coal, pebbles) inside the container, remember to adapt the tap to the base of the filter or make a hole of approximately 1/2 inch for the filtered water to exit (use a stopper or small stick as a lid).

If cleaning and disinfection of the components with a bleach solution is not available, it is recommended to wash with clean water only and dry everything in the sun until the materials are completely dry;

All container fillings must be gentle and also made ever over the screens to prevent the sudden turning of the raw water inside the container;

Do not allow the sand to dry out. Keep the raw water space in the container always full. For that, one must also leave the water circulating always; this is to drain the water present in the filter and fill it again every day.

The water inlet must sealing of the upper part with an opaque plastic bag is recommended to prevent the passage of light as well as insects.

In addition, it is recommended to wait for 1 month after the first filling to warrant that the biofilm be created since it is fundamental in water purification;

Only then (after one month) it is suitable for human consumption!