Safeguarding Your Plate: How High-Pressure Processing Enhances Food Safety and Quality

For the past few decades, consumer demand for minimally processed, healthier food has increased, prompting the exploration of alternative preservation methods beyond traditional heat treatments. High Pressure Processing (HPP) is a non-thermal method that ensures food safety while extending shelf life (2). The origins of HPP can be traced back to the late nineteenth century (1880-1899), including applications such as starch conversion to sugar and phenol manufacture (1). It was only in 1990 that HPP was first considered in Japan for producing pressure-treated jams and jellies. This initial application sparked a significant surge in innovation, leading to the extension of this technology to a wide variety of foods and beverages. Manufacturers in Europe and the USA have embraced HPP for products like guacamole and sliced cooked ham. Since then, HPP has been rapidly adopted, extending its use to an even wider range of products. More importantly, it provides major benefits to the food industry compared to heat treatment, driving further expansion and innovation globally.

Benefits of HHP in Food Processing

- Extended Shelf Life: HPP significantly extends the shelf life of food products by inactivating spoilage microorganisms and enzymes. This contributes to less food waste, better supply chain operations, and convenience for consumers who can store products for longer periods.

- Enhanced Food Safety: Efficient inactivation of pathogens such as E. coli, Salmonella, Listeria, Vibrio, and Norovirus enables food safety and ensures compliance with authorities’ requirements for food consumption. Re-contamination of the product with microorganisms during or after production can be avoided by the ‘In-pack’ process (see below) as the food is processed in its final packaging. The latter can also contribute to reducing foodborne illnesses and alleviating public health and economic losses (product recalls).

- Nutritional and Sensory Quality: One of the main advantages of HPP is the maintenance of the sensory and organoleptic characteristics of the food product, which are otherwise affected by heat processing. HPP-treated foods maintain their original flavor, color, and taste. This is particularly important for products like juices, guacamole, and salsas, where fresh taste and appearance are key selling points.

- Clean-Label Products: The technology offers a natural preservation alternative, reducing the need for preservatives or additives.

- Eco-friendly: HPP requires electricity and water, which can be recycled.

Although most common HPP-treated foods include juices and meat products, the technology suits most foods. Limitations include processing of low moisture (<40%) and aerated foods, but also spore inactivation cannot be achieved without high pressures (>600 MPa) and temperatures (>100 °C). The technological challenges associated with using HPP and current strategies to overcome them can be found in “Unlocking the Potential of High Hydrostatic Pressure: A Fresh Approach to Food Preservation”.

How does HPP work?

Usually, food products are pre-packed under vacuum (‘In-pack’ process) in flexible and compressible packaging. The products are placed in baskets which are then loaded and sealed in a pressure chamber/vessel. The machine fills the vessel with water pressure transmitting fluid, and intensifiers pump high pressure water until the target pressure is reached. Hydrostatic pressures of 600 MPa (6,000 bar) are typically selected for commercial applications, where food is subjected to these pressures for several seconds or minutes. After the holding time, the pressure is released, the baskets are removed from the vessel, and the products are ready to be sourced out in the market under refrigeration. Processing parameters like pressure, time, and temperature are selected based on the specific application. For foods, these parameters are designed to inactivate the most relevant pathogens or spoilage microorganisms for each product category, ensuring food safety and shelf life extension.

Figure 1. Example of industrial HPP equipment from Hiperbaric.

HPP efficacy & influencing factors

Several factors must be considered when applying HPP, as they can affect its efficacy. These factors include those related to microorganisms, extrinsic factors associated with HPP processing parameters (e.g., temperature, time, packaging atmosphere, pressure), and intrinsic food factors, such as composition and physicochemical characteristics (e.g., pH, aw, antimicrobials). Commonly used food preservation techniques are primarily evaluated based on their effectiveness in eliminating pathogens to achieve food safety and extend product shelf life by concurrent inactivation of spoilage microorganisms. This assessment is conducted by validation studies that follow the inactivation of a relevant microorganism for a specific product to an acceptable level.

Microbial inactivation with HPP

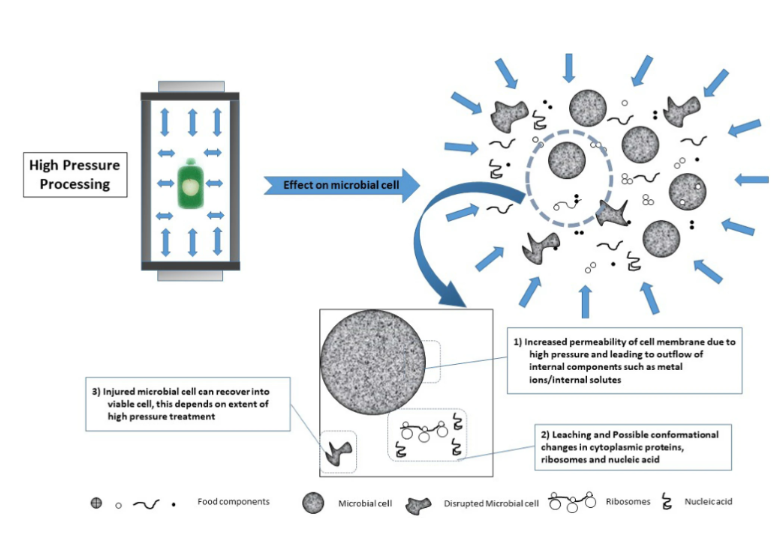

Microbial inactivation is achieved through changes in protein structure and biochemical reactions, DNA synthesis disruption, and alterations in fluidity or loss of integrity of the cell membrane (Figure 2). However, under milder HPP conditions, some microorganisms can withstand HPP, compromising its efficacy. This depends on the type, species, strain, and physiological state (2). Strain variability plays a significant role in resistance, and although it is well-described for thermal processing, there is limited information on its impact during HPP (3).

Figure 2. Schematic representation of cell membrane modifications during high pressure processing (adapted from 4)

To obtain a deeper insight into microorganisms’ resistance to HPP, we investigated four species with 10 different strains each, corresponding to foodborne pathogens and spoilage microorganisms relevant to HPP-treated foods (5).

- Listeria monocytogenes

- Escherichia coli

- Lactiplantibacillus plantarum

- Saccharomyces cerevisiae

By targeting these microorganisms with milder HPP conditions than those commercially applied, we aimed to record how inactivation varies between species and strains but also identify robust candidates that could be used for HPP validation studies in foods. Interestingly, the two pathogens (Listeria monocytogenes and Escherichia coli) were the most resistant among all species with significant strain variability under most HPP conditions. In addition, resistant strains were identified as potential markers for future HPP validation studies to ensure food safety. Moreover, HPP at 300 MPa for 10 min significantly reduced most of the spoilage microorganisms. Although milder HPP conditions enabled the study of inactivation patterns between species and strains, it is essential to remember that commercially available foods treated with HPP alone are exposed to more intense treatments to ensure food safety. Nevertheless, the results obtained under mild conditions in this study can lay the foundation for process optimization when HPP is combined with other preservation methods for safe food production, operating cost reduction, and mitigation of HPP-associated food alterations.

Transforming Food Processing with HPP

High pressure processing is a very promising technology but also a safe, nutritious and sustainable alternative to current food preservation methods. Although HPP-treated products have been in supermarkets for years, there is significant potential for innovation and expansion to other markets (e.g., pet food, and plant-based foods). As manufacturers invest more in this processing technology, the need for additional research grows. Further knowledge can enhance existing inactivation strategies (e.g., hurdle technology) and ensure that food production is safer and more environmentally friendly for consumers.

References:

- Balasubramaniam, V. M. B., & Mart, S. I. (2015). Principles and Application of High Pressure – Based Technologies in the Food Industry. https://doi.org/10.1146/annurev-food-022814-015539

- EFSA. (2022). The efficacy and safety of high‐pressure processing of food. EFSA Journal, 20(3). https://doi.org/10.2903/j.efsa.2022.7128

- Masschalck, B., García-Graells, C., Van Haver, E., & Michiels, C. W. (2000). Inactivation of high pressure resistant Escherichia coli by lysozyme and nisin under high pressure. Innovative Food Science and Emerging Technologies, 1(1), 39–47. https://doi.org/10.1016/S1466-8564(99)00006-5

- Sehrawat, R., Kaur, B. P., Nema, P. K., Tewari, S., & Kumar, L. (2021). Microbial inactivation by high pressure processing: principle, mechanism and factors responsible. Food Science and Biotechnology, 30(1), 19–35. https://doi.org/10.1007/s10068-020-00831-6

- Tsagkaropoulou, T., & Karatzas, K. A. G. (2024). Microbial species and strain heterogeneity affect resistance to high pressure processing. Innovative Food Science and Emerging Technologies, 94(March), 103645. https://doi.org/10.1016/j.ifset.2024.103645

Further Reading

Non-thermal plasma (NTP) for the improvement of food safety and quality

The Impact of Strain Variability on the Inactivation Efficacy of Ultrasound Technology

Exploring Pulsed Electric Field (PEF) Microbial Inactivation for Food Processing

Using AI to evaluate non-thermal processing efficacy and assess the global impact

Unlocking the Potential of High Hydrostatic Pressure: A Fresh Approach to Food Preservation

Understanding Consumer Perception in Food Product Development: Key to Market Success