Quality Standardization of Fresh Fruit and Vegetables to Reduce Food Waste and Loss

Why is quality standardization of fresh fruit and vegetables important to reduce food waste and loss?

Healthy lifestyles drive consumers to increase demand for fresh fruits and vegetables. Fresh fruit and vegetables need to be maintained after postharvest because they are perishable, have a short shelf life, and are susceptible to quality deterioration due to unfavorable external factors such as inappropriate handling, transportation, climate change, weather variability, and contamination. Unpreventable deterioration of fresh fruit and vegetable quality and poor management of perishable produce will cause loss along the supply chain that drives food waste and loss.

FAO (2019) launched two new indicators which are the Food Loss Index and the Food Waste Index as reference definitions of food waste and food loss.

- Food loss is “the decrease in the quantity or quality of food resulting from decisions and actions by food suppliers in the chain, excluding retail, food service providers, and consumers. Thus, food loss refers to a decrease in mass (dry matter) or nutritional value (quality) of food that was originally intended for human consumption.”

- Food waste is “the decrease in the quantity or quality of food resulting from decisions and actions by retailers, food services, and consumers. Food waste refers to food appropriate for human consumption being discarded, whether or not it is kept beyond its expiry date or left to spoil.”

According to some studies, global annual losses and wastage amount to roughly 35% of initial production, or 1.3 billion tonnes of food destined for human consumption (FAO 2011). Many international authorities and journal article authors typically quote a general range of 30–50% post-harvest losses. FAO (2011) currently uses 45% of global losses of both roots/tuber crops and fruits/vegetables (Kitinoja and Kader, 2015).

The measurement approach of food waste and loss in every stage of the supply chain will be more effective and efficient in assessing what is the main issue and how to solve and avoid it. The approach in every stage of post-harvest loss, including harvesting, handling, storage, processing, packaging, transportation, and marketing, to understanding the nature of the problem will help in designing solutions. Mitigation planning is the most effective and efficient way to reduce food loss from postharvest by applying the standardization and qualification of vegetables and fruit to maintain the next supply chain.

How can food waste and the loss of fresh fruit and vegetables be reduced?

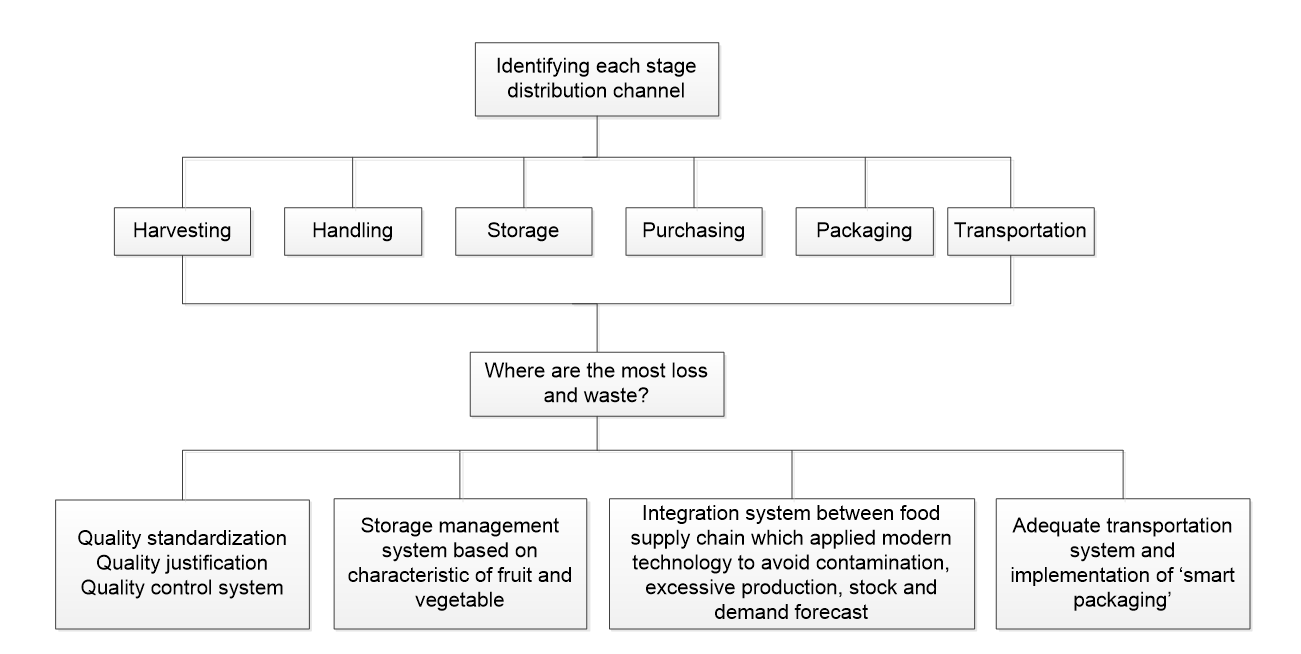

Possible avenues to reduce loss and waste in fresh fruit and vegetables are analyzing fresh delivery patterns and inventory management in retail and food service operations, identifying key steps in each distribution channel where loss and waste are most likely to occur, and developing techniques that minimize loss and waste in the most vulnerable steps. Focusing on identifying each stage of the supply chain where loss and waste occur and developing techniques that minimize loss and waste is the most comprehensive mitigation plan to reduce post-harvest loss. Most of the post-harvest loss correlated with the quality of fresh vegetables and fruit. Implementation of quality standardization is a must to reduce post-harvest loss.

Perspective alignment about quality from the retail client and consumer will be good practice to implement quality standardization to reduce post-harvest loss. The remaining shelf life of the product, visual appearance, taste-related attributes (firmness, sugar content, organic acid content, and tissue juiciness), eating experience, and aesthetic issues (fruit color, size, shape, blemish severity) that affect consumer purchase decisions can be used as a reference for quality parameter alignment. A quality control system can be implemented at the retailer distribution center that involves statistical sampling protocols and quantitative measures of quality attributes, including fruit firmness, temperature, skin color, juice total soluble solids (TSS) content, and juice total titratable acidity.

Figure 1. Step by step to reduce food waste and loss

How do you implement quality standardization of fresh fruit and vegetables?

Food waste and loss of fresh fruit and vegetables commonly happen in the initial stage of the supply chain. Characteristics of fruit and vegetables as perishable products cause rapid decline of freshness and product quality. Therefore, a comprehensive management system is needed to prevent waste and loss in the early stage of the supply chain. Quality standardization of fresh fruit and vegetables is an effective and efficient system to apply in the early stages of harvesting, handling, and storage. Quality evaluation of fresh fruits and vegetables is the first step in determining specifications based on preferences from customers, suppliers, buyers, and quality teams.

References to defined characteristics and features from industry standards, consumer or grade standards, business or voluntary label standards, and legal standards will be made from various points of view about standard quality. This standard will serve as a gauge to ensure that the highest-quality product meets and exceeds the expectations of the customers. Establishing standard specifications requires taking into account several factors, such as:

- There can be multiple versions of a specification, for example, from supplier to packing team or from buyer to QC teams. Therefore, assessment, validation, and verification are needed to break down specifications that can facilitate stakeholders’ concerns about achieving customer satisfaction as a reference.

- Specifications should be written to match what customers value and benchmark. Consumer panels or surveys can be used to estimate specifications. “Ugly” lines might be used to gauge how much a consumer can put up with errors. There should be a process for version control and consistent changes to all versions if updates are made.

- A good specification is a short specification. Long specifications may seem impressive, but they are difficult to fully implement and can lead to distraction, confusion, and inefficiency, which raises costs.

- Suppliers should be involved in setting specifications for feedback on which specifications are hard to meet and to build trust.

How do you justify the specification of fresh fruit and vegetables?

The implementation of standard quality fresh fruit and vegetables must be clear and measurable due to the involvement of multiple stakeholders from each stage of the supply chain. Consequently, specification justification is required to guarantee that the established parameters and attributes can be used to maintain the product’s consistency in quality. Justification to support the requirement quality for fresh fruits and vegetables such as:

- Photographs must be included in specifications to eliminate uncertainty.

- Waste can result from overgrazing caused by overcautious suppliers or overly eager quality control personnel. Solutions include training, improving working conditions, and/or technology. The issuing of warnings for minor defects rather than a rejection of loads will help suppliers pack to specifications more confidently.

- Minimum and maximum size criteria can greatly impact crop utilization. Reducing these standards will save expenses and increase efficiency. Restrictions on size should only be tightened in cases where there is proof that customers value this quality.

- Quality specifications left in place for a long period without re-evaluation can cause waste. When seasonal conditions have an impact on quality, temporary requirements may be employed. Clear internal policies and procedures should govern these kinds of adjustments. If a request is made frequently, it should be included in the specification.

- A shelf-life assessment protocol should be included in the specifications. For example: “A minimum of one pack per production run to be held in conditions that replicate the value chain from dispatch to consumption

What is the method for determining the quality of fresh food and vegetables?

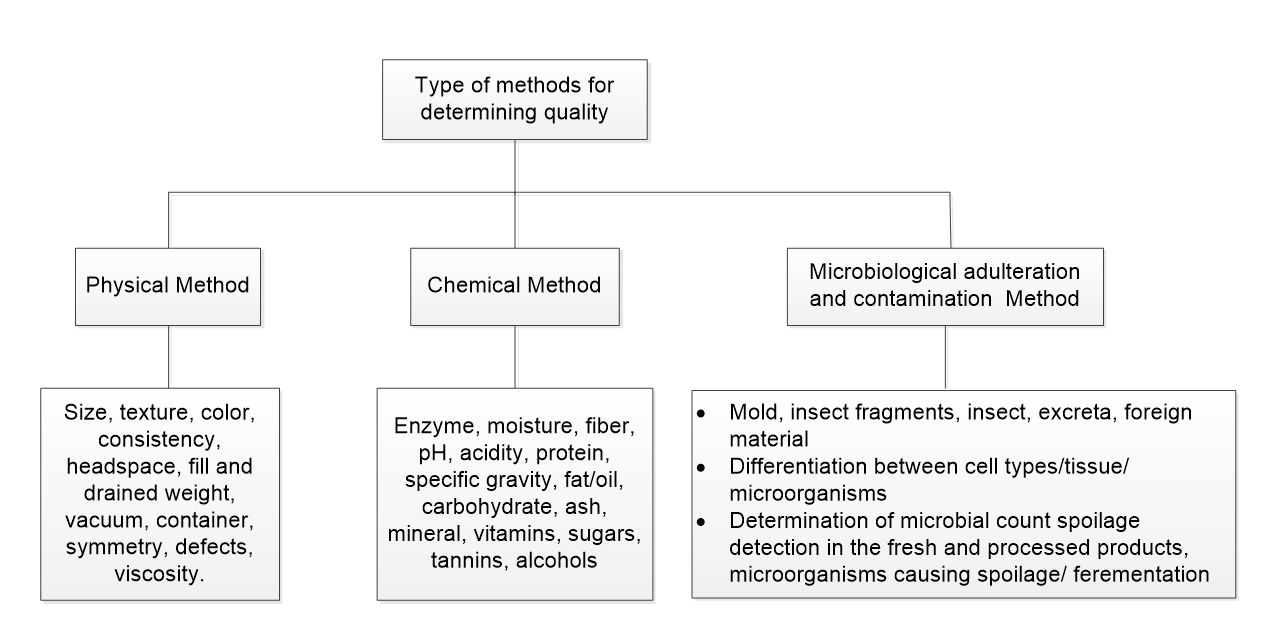

Multiple techniques were employed to measure quality parameters and attributes, such as physical, chemical, and microbiological adulteration, and contamination. The measurement findings will serve as a benchmark for quality determination in the form of quantitative data that can be utilized to track the consistency of fresh fruit and vegetable quality based on attributes and product categories.

Figure 2. Type of method for determining quality fresh fruit and vegetable

Qualitative approaches can also be used to determine quality, and they can complement the findings of quantitative data. Among the qualitative techniques are:

- Evaluation of whether the product is defective

- The level of tolerance for each type of defect, such as cuts, bruises, disease, low-temperature injury, and physiological disorders, should be determined.

- During quality evaluation, the percentage of fruit and vegetables with each class of defect can be determined as a guide to overall product quality

Reducing food waste and loss will be possible through system management and implementation techniques that are implemented at each stage of the supply chain. The first line of defense against post-harvest loss is to implement systems that identify each stage of the food supply chain, apply quality standards, justify specifications, and determine the quality of fresh fruit and vegetables.

The implementation of this system will be challenged because of improper pre-harvest and harvesting methods, a lack of coordination and information sharing among the food supply chain’s stakeholders, and the limitations of technologies that can produce edible quality in developing nations. This challenge can be overcome properly if the management strategy to reduce food waste and loss is planned comprehensively so that parties involved in the food supply chain (consumers, distributors, and producers) experience optimal benefits.

Reference

FAO (2011) Global food losses and food waste – extent, causes and prevention, Rome

FAO (2019) The State of Food and Agriculture 2019. Moving forward on food loss and waste reduction, Rome. License: CC BY-NC-SA 3.0 IGO. 182p

Kitinoja L, Kader AA (2015) Measuring post-harvest losses of fresh fruits and vegetables in developing countries. Postharvest Education Foundation. PEF White paper 15-02. The Postharvest Education Foundation, La Pine. 26pp

Bancal, V and Ray, R.C. 2022. Overview of Food Loss and Waste in Fruits and Vegetables: From Issue to Resources: Fruits and Vegetable Wastes. Springer, Singapore.

Florkowski, W.J., Banks, R.L., Shewfelt, R.L. and Prussia, S.E. 2022. Postharvest Handling: A Systems Approach. Academic Press, London.

Goyal, M.R and Ahmad, F. 2023. Quality Control in Fruit and Vegetable Processing: Method and Strategies. CRC Press, USA.

Siddiqui, M, W. 2020. Fresh Cut Fruits and Vegetables: Technologies and Mechanisms for Safety Control. Academic Press, UK.

Further reading:

Smart Packaging Application in Bakery Products

Smart Packaging Functionality and Benefits

Combination Enzymes in Bakery Products