Nanotechnology in Food Science: Food Safety, Food Packaging and Food Processing

Nanomaterial Applications in the Food Sector. Toxicological Assessment, Safety Issues, Regulatory Aspects, and Health Risks of NMs.

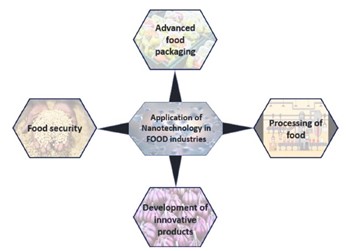

The food industry has a lot of potential for developing completely new products and processes thanks to the development of nanotechnology. Food additives (inside nanoparticles) and food packaging (outside nanomaterials) are two ways that nanotechnology can be used in the food sector (1). Nanocomposites are one of the most active areas of food packaging research in the field of food nanoscience (2). Figure 1 illustrates how nanotechnology is being used in the food industry.

Figure 1. Applications of nanotechnologies in the food sector (3)

Nanotechnology in Food Packaging/Preservation

Food preservation and protection from multiple threats, such as insects, bacteria, physical damage, and dirt, are two of the primary goals of packaging. They have to be simple to handle and distribute. Nanotechnology has the potential to enhance the mechanical barrier and the antimicrobial, which will prevent the entry of microorganisms in the food and increase the food barrier qualities (Figure 2). Consequently, it is an extremely promising material for food packaging.

Figure 2. Properties of nanomaterials (3)

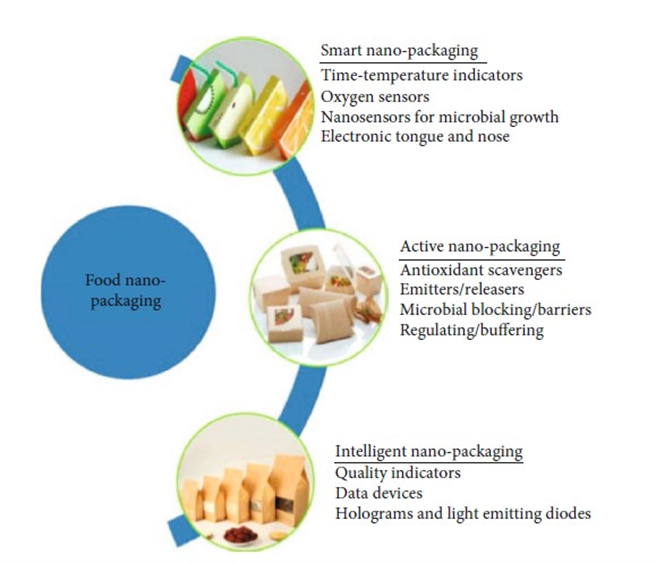

The classification in food nanopackaging is shown in Figure 3. Some active packages extend the shelf life of the food by dispensing specific components, and other intelligent packages alert consumers to the product’s safety. On top of that, nanosensors in smart packaging are used for tracking the condition of containers and products. Additionally, there are probiotic-infused antimicrobial packaging, which are a relatively recent technique for biopreservation. The ideal characteristics for food packaging are listed in Table 1, along with the best nanomaterials for the intended purpose. Biodegradable plastic and its resources are recognised as a potent tool for reducing the effects of petroleum-based plastics on the environment (4). However, no biobased materials can match the performance of petroleum-based products. It is necessary to enhance the physical characteristics of biobased packing materials, such as their thermal stability, barrier qualities, and mechanical capabilities. It has been demonstrated that adding carbon nanotubes, nanoclays, and nanocellulose to bioplastics as a nanoreinforcement is an efficient and effective strategy to improve these qualities (5).

Figure 3. Classification of nanofood packaging (6)

Table 1. Nanomaterials and their selection in brief

| Desired property | Effective Nanomaterial | Ref |

| Elimination of enzymatic browning | Thiol-functionalized nanoparticles built from silica | Bumbudsanpharoke et al., 2015 |

| Antimicrobial property | Silver nanoparticles (AgNPs), ZnO nanostructures, titanium nanoparticles (TiO2 and tin) | Bumbudsanpharoke et al., 2015 |

| Moisture barrier Reinforcement | Nanoclays | Bumbudsanpharoke et al., 2015 |

| Qualities of reinforcement or filling | Starch nanocrystals Cellulose nanostructures | |

| Sensors | Carbon nanotubes | Bumbudsanpharoke et al., 2015 |

These factors have led some of the leading packaging firms in the world to investigate and conduct research in order to determine the potential of polymer nanotechnology (7). Silver nanoparticles and nanoclay represent most of the nanoempowered food packaging available on the market others like zinc oxide and titanium share little of the current market (3).

Nanotechnology in Food Safety

Significant advancements in the field of food safety have been enabled by nanotechnology also. Food contamination processes have a significant demand for a fast, reliable, and sensitive detection technology (8). Nanosensors can play a critical role in ensuring food safety and protecting food quality along the supply chain. Nanosensors are able to identify pathogens, toxins, allergens, spoilage, and adulteration in food samples and provide consumers, producers, and regulators with immediate feedback. For instance, when food has been contaminated or has exceeded its expiration date, nanosensors built into smart packaging can change colour or send signals (Figure 3). Additionally, wearable sensors or handheld scanners that can scan food items and show information on a smartphone app can be built with nanosensors. A nanosensor that may identify airborne contaminants in the food supply chain was created by a professor at the University of California Riverside Bourns College of Engineering. A nanosensor array used in his research can identify minute concentrations of dangerous airborne chemicals. To detect airborne pollutants down to the parts per billion (ppb) level, it uses functionalized carbon nanotubes, which are 100,000 times finer than human hair. The device’s prototype included a computer chip, USB ports, and humidity and temperature sensors. The prototype’s second version was muted in order to incorporate a GPS unit, a Bluetooth unit to sync it with a smart phone, and Wi-Fi capabilities (9).

Nanotechnology in Food Processing / New Product Development

Nanotechnologies have significantly advanced the field of food processing. Given that food products must meet strict quality standards and that dietary needs are driving up demand for novel products like low-calorie and low-fat foods, nanomaterials in the food industry must improve the separation process (10). One of the most useful techniques based on nanotechnology, termed nanofiltration, has enormous potential for processing food. Examples of applications for nanoporous membranes include water filtration and softening (11). The dairy sector can use this nanotechnology in a variety of ways. The dairy industries use nanotechnologies to standardise milk, fractionate the proteins present in the milk, and improve the microbiological quality (12). When compared to the standard filtration procedure, this approach has a number of advantages. Less processing steps, less energy use, better end product quality, and higher separation efficiency are a few of them.

Related Health risks, safety concerns, and regulatory aspects

Due to subsequent transfer of particle nanomaterials from the packaging into the food as a result of poor packing performance, consuming foods that have come into touch with nanopackaging may present an exposure route and represent a serious health risk. This effect would be significantly affected by the ingestion rate of each particular food, packing matrix type, degree of migration, and toxicity of the utilised nanomaterial (13). Overconsumption, bioaccumulation, and increased activity of nano-based goods negatively impact health and present safety and health problems (13, 14). According to a number of studies, silver nanoparticles from packaging materials may contaminate food and be consumed by people (15).

Furthermore, a single oral intake of ZnO nanoparticles could cause issues like lung, kidney and liver harm (16). The use of titanium oxide and its final disposal can have an impact on both people and the environment, which raises the possibility of environmental and human health risks (17).

Understanding traceability and monitoring of the physical, chemical, and functional properties of nanoscale materials is complicated by the interaction between nanoscale materials and their environment (18). Knowledge specifically related to laws governing food applications of nanotechnologies has been compiled by Chaudhry et al., 2008 (19), Gergely et al., 2010 (20), Hodge et al., 2014 (21), Rasmussen et al., 2019 (22) and Schoonjans et al., 2023 (23). The European Food Safety Authority (EFSA) is responsible for assessing the risks associated with small particles, including nanoparticles, in goods used in the food supply chain in the EU. This process has been the subject of extensive scientific analysis for more than ten years. The guidelines for regulatory safety assessments and data requirements have been established as more experience has been acquired with evaluating novel foods, food contact materials, food/feed additives, and pesticides. Amenta et al. 2015 (24) and Rasmussen, Rauscher, Gottardo, et al., 2019 (22) provide a thorough analysis of the legal requirements for the use of nanotechnologies in food in the EU (and beyond). The newly updated Commission Recommendation of 10.06.2022 on the definition of nanomaterial (EU/C 229/01), which is not relevant in the context of food, and Regulation (EU) 2015/2283 on innovative foods, which offers a definition of engineered nanomaterial, are the key regulatory instruments in Europe. It has been clarified by the European Commission that the provisions of the Novel Food legislation extend to food additives, feed additives, and nutrient sources (EFSA Scientific Committee, 2021a) (25-28). Regulation (EU) No 10/2011 governs the use of chemicals in nanoform in plastic food contact materials (FCMs). Recent releases from the European Food Safety Authority (EFSA) include two directives. One describes the technical requirements to determine whether there are small particles present or whether the properties at the nanoscale persist while the product is being used, and the other describes the scientific risk assessment and appropriate safety testing of nanomaterials to ensure consumer protection (EFSA Scientific Committee, 2021a,b) (29-32).

References

- Jaiswal, L., Shankar, S. and Rhim, J.-W. (2019) Applications of nanotechnology in food microbiology. Methods in Microbiology, vol. 46, pp. 43–60, Academic Press.

- Vijayakumar, M. D., Surendhar, G. J., Natrayan, L., Patil, P.P., Bupathi Ram, P.M. and Paramasivam, P. (2022) Evolution and Recent Scenario of Nanotechnology in Agriculture and Food Industries. Review article. Hindawi – Journal of Nanomaterials, Volume 2022, Article ID 1280411, 17 pages, https://doi.org/10.1155/2022/1280411

- Chadha, U., Bhardwaj, P., Kumaran, S., Selvaraj, S.K., Arasu, K., Praveena, S., Pavan, A., Khanna, M., Singh, P., Singh, S., Chakravorty, A., Badoni, B., Banavoth, M., Sonar, P. and Paramasivam, V. (2022) Current Trends and Future Perspectives of Nanomaterials in Food Packaging Application. Review Article. Hindawi – Journal of Nanomaterials. Article ID 2745416, 32 pages, https://doi.org/10.1155/2022/2745416

- Enescu, D., Cerqueira, M.A., Fucinos, P. and Pastrana, L.M. (2019) Recent advances and challenges on applications of nanotechnology in food packaging. A literature review. Food and Chemical Toxicology, vol. 134, p. 110814, https://doi.org/10.1016/j.fct.2019.110814

- Mei, L. and Wang, Q. (2020) Advances in using nanotechnology structuring approaches for improving food packaging. Annual Review of Food Science and Technology, vol. 11, no. 1, pp. 339–364, https://doi.org/10.1146/annurev-food-032519-051804

- Veeman, D., Sai, M. S., Sureshkumar, P. et al. (2021) Additive manufacturing of biopolymers for tissue engineering and regenerative medicine: an overview, potential applications, advancements, and trends. International Journal of Polymer Science, vol. 2021, Article ID 4907027, 20 pages, https://doi.org/10.1155/2021/4907027

- Dobrucka, R. (2014). Application of Nanotechnology in Food Packaging. Journal of Microbiology, Biotechnology and Food Sciences, 3(5), 353–359. Retrieved from https://office2.jmbfs.org/index.php/JMBFS/article/view/6994

- Babu, P.J. (2022) Nanotechnology mediated intelligent and improved food packaging, International Nano Letters, vol. 12, no. 1, pp. 1–14, https://doi.org/10.1007/s40089-021-00348-8

- https://www.foodnavigator-usa.com/Article/2013/06/18/Nanosensor-being-developed-for-food-safety#

- Ramesh, T., Sathiyagnanam, A. P., De Poures, M. V. and Murugan, P. (2022) A Comprehensive Study on the Effect of Dimethyl Carbonate Oxygenate and EGR on Emission Reduction, Combustion Analysis, and Performance Enhancement of a CRDI Diesel Engine Using a Blend of Diesel and Prosopis juliflora Biodiesel, International Journal of Chemical Engineering, Article ID 5717362, 12 pages, https://doi.org/10.1155/2022/5717362

- Karthick, M., Meikandan, M., Kaliappa, S. et al., (2022) “Experimental Investigation on Mechanical Properties of Glass Fiber Hybridized Natural Fiber Reinforced Penta-Layered Hybrid Polymer Composite, International Journal of Chemical Engineering, Article ID 1864446, 9 pages, https://doi.org/10.1155/2022/1864446

- Lugani, Y., Oberoi, S. and Rattu, G. (2021) Nanotechnology in food industry–applications and future perspectives, In book: Sustainable Agriculture Reviews 55, Micro and Nano Engineering in Food Science Vol 1 (pp.71-92), https://doi.org/10.1007/978-3-030-76813-3_3

- Cushen, M., Kerry, J., Morris, M., Cruz-Romero, M., & Cummins, E. (2012). Nanotechnologies in the food industry–Recent developments, risks and regulation. Trends in Food Science & Technology, 24(1), 30–46. https://doi.org/10.1016/j.tifs.2011.10.006

- Jovanovic, B. (2015). Critical review of public health regulations of titanium dioxide, a human food additive. Integrated Environmental Assessment and Management, 11, 10–20. https://doi.org/10.1002/ieam.1571

- Echegoyen, Y., & Nerín, C. (2013). Nanoparticle release from nano-silver antimicrobial food containers. Food and Chemical Toxicology, 62, 16–22. https://doi.org/10.1016/j.fct.2013.08.014

- Esmaeillou, M., Moharamnejad, M., Hsankhani, R., Tehrani, A. A., & Maadi, H. (2013). Toxicity of ZnO nanoparticles in healthy adult mice. Environmental Toxicology and Pharmacology, 35(1), 67–71. https://doi.org/10.1016/j.etap.2012.11.003

- Yang, Y., Doudrick, K., Bi, X., Hristovski, K., Herckes, P., Westerhoff, P., & Kaegi, R. (2014). Characterization of food-grade titanium dioxide: The presence of nanosized particles. Environmental Science & Technology, 48(11), 6391–6400. https://doi.org/10.1021/es500436x

- He, X., Fu, P., Aker, W. G., & Hwang, H. M. (2018). Toxicity of engineered nanomaterials mediated by nano–bio–eco interactions. Journal of Environmental Science and Health, Part C, 36(1), 21–42. https://doi.org/10.1080/10590501.2017.1418793

- Chaudhry, Q., Scotter, M., Blackburn, J., Ross, B., Boxall, A., Castle, L., & Watkins, R. (2008). Applications and implications of nanotechnologies for the food sector. Food Additives and Contaminants, 25(3), 241–258.https://doi.org/10.1080/02652030701744538

- Gergely, G.,Wéber, F., Lukács, I., Illés, L., Tóth, A., Horváth, Z., Balázsi, C. (2010). Nano-hydroxyapatite preparation from biogenic raw materials. Open Chemistry, 8(2), 375–381. https://doi.org/10.2478/s11532-010-0004-4

- Hodge, G. A., Maynard, A. D., & Bowman, D. M. (2014). Nanotechnology: Rhetoric, risk and regulation. Science and Public Policy, 41(1), 1–14. https://doi.org/10.1093/scipol/sct029

- Rasmussen, K., Rauscher, H., Gottardo, S., Hoekstra, E., Schoonjans, R.,Peters, R., Aschberger, K. (2019) Chapter 13 – Regulatory Status of Nanotechnologies in Food in the EU, Nanomaterials for Food Applications. Micro and Nano Technologies, 381-410. https://doi.org/10.1016/B978-0-12-814130-4.00013-0

- Schoonjans, R., Castenmiller, J., Chaudhry, Q., Cubadda, F., Daskaleros, T., Franz, R., Gott, D., Mast, J., Mortensen, A. Oomen, A .G., Rauscher, H., Weigel, S., Astuto, M.C., Cattaneo, I., Barthelemy, E., Rincon, A., Tarazona, J. (2023) Trends in Food Science & Technology, 134 98–111, https://doi.org/10.1016/j.tifs.2023.01.017

- Amenta, V., Aschberger, K., Arena, M., Bouwmeester, H., Moniz, F.B., Brandhoff, P., Gottardo, S., Marvin, H.J.P., Mech, A., Pesudo, L.Q.,Rauscher, H., Schoonjans, R., Vettori, M.V., Weigel, S., Peters, R. J. (2015) Regulatory aspects of nanotechnology in the agri/feed/food sector in EU and non-EU countries, Regul Toxicol Pharmacol, 73(1):463-76. https://doi.org/10.1016/j.yrtph.2015.06.016, Epub 2015 Jul 11.

- EFSA FAF Panel (EFSA Panel on Food Additives and Flavourings), Younes, M., Aquilina, G., Castle, L., Engel, K.-H., Fowler, P., Frutos Fernandez, M. J., Fürst, P., Gundert-Remy, U., Gürtler, R., Husøy, T., Manco, M., Mennes, W., Moldeus, P., Passamonti, S., Shah, R., Waalkens-Berendsen, I., Wölfle, D., Corsini, E.,… Wright, M. (2021a). Safety assessment of titanium dioxide (E171) as a food additive. EFSA Journal, 19(5), Article e06585. https://doi.org/10.2903/j.efsa.2021.6585

- EFSA (European Food Safety Authority). (2021a). Technical report on the request for technical assistance on orthosilicic acid-vanillin complex (OSA-VC). EFSA Supporting publication, 18(9), 6838E. https://doi.org/10.2903/sp.efsa.2021.EN-6838

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens), Turck, D., Bohn, T., Castenmiller, J., De Henauw, S., Ildico Hirsch-Ernst, K., Maciuk, A., Mangelsdorf, I., McArdle, H. J., Naska, A., Pelaez, C., Pentieva, K., Siani, A., Thies, F., Tsabouri, S., Vinceti, M., Cubadda, F., Frenzel, T., Heinonen, M.,… Knutsen, H. K. (2021a). Safety of iron hydroxide adipate tartrate as a novel food pursuant to Regulation (EU) 2015/2283 and as a source of iron in the context of Directive 2002/46/EC. EFSA Journal, 19(12), Article e06935. https://doi.org/10.2903/j.efsa.2021.6935

- EFSA Scientific Committee, More, S., Bampidis, V., Benford, D., Bragard, C., Halldorsson, T., Hernández-Jerez, A., Bennekou, S. H., Koutsoumanis, K., Lambré, C., Machera, K., Naegeli, H., Nielsen, S., Schlatter, J., Schrenk, D., Silano, V., Turck, D., Younes, M., Castenmiller, J., Schoonjans, R. (2021a). Guidance on technical requirements for regulated food and feed product applications to establish the presence of small particles including nanoparticles. EFSA Journal, 19 (8), Article e06769. https://doi.org/10.2903/j.efsa.2021.6769

- EFSA (European Food Safety Authority). (2021b). Outcome of the public consultation on the draft Guidance on technical requirements for regulated food and feed product applications to establish the presence of small particles including nanoparticles. EFSA Supporting Publications, 18(8), 6804E. https://doi.org/10.2903/sp.efsa.2021. EN-6804

- EFSA FAF Panel (EFSA Panel on Food Additives and Flavourings), Younes, M., Aquilina, G., Castle, L., Engel, K.-H., Fowler, P., Fürst, P., Gürtler, R., Gundert- Remy, U., Husøy, T., Manco, M., Mennes, W., Moldeus, P., Passamonti, S., Shah, R., Waalkens-Berendsen, D. H., Wölfle, D., Wright, M., Boon, P.,…Fernandez, M. J. F. (2021b). Re-evaluation of polydextrose (E 1200) as a food additive. EFSA Journal, 19 (1), Article e06363. https://doi.org/10.2903/j.efsa.2021.6363

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens), Turck, D., Castenmiller, J., De Henauw, S., Hirsch-Ernst, K. I., Kearney, J., Maciuk, A., Mangelsdorf, I., McArdle, H. J., Naska, A., Pel´aez, C., Pentieva, K., Siani, A., Thies, F., Tsabouri, S., Vinceti, M., Cubadda, F., Frenzel, T., Heinonen, M., … Knutsen, H. K. (2021b). Safety of calcidiol monohydrate produced by chemical synthesis as a novel food pursuant to Regulation (EU) 2015/2283. EFSA Journal, 19 (7), Article e06660. https://doi.org/10.2903/j.efsa.2021.6660

- EFSA Scientific Committee, More, S., Bampidis, V., Benford, D., Bragard, C., Halldorsson, T., Hern´andez-Jerez, A., Hougaard Bennekou, S., Koutsoumanis, K., Lambré, C., Machera, K., Naegeli, H., Nielsen, S., Schlatter, J., Schrenk, D., Silano, V., Turck, D., Younes, M., Castenmiller, J., … Schoonjans, R. (2021b). Guidance on risk assessment of nanomaterials to be applied in the food and feed chain: Human and animal health. EFSA Journal, 19(8), Article e06768. https://doi.org/10.2903/j.efsa.2021.6768