Materials used in food packaging

This post is also available in:

This post is also available in:

![]() Español (Spanish)

Español (Spanish) ![]() Ελληνικά (Greek)

Ελληνικά (Greek)

What are the types of food packaging?

The food packaging materials help keep the food fresh and safe. Every material is used to serve different purposes. For example, they can prolong the product’s shelf-life, protect against contamination, preserve freshness, and provide information to consumers about the product.

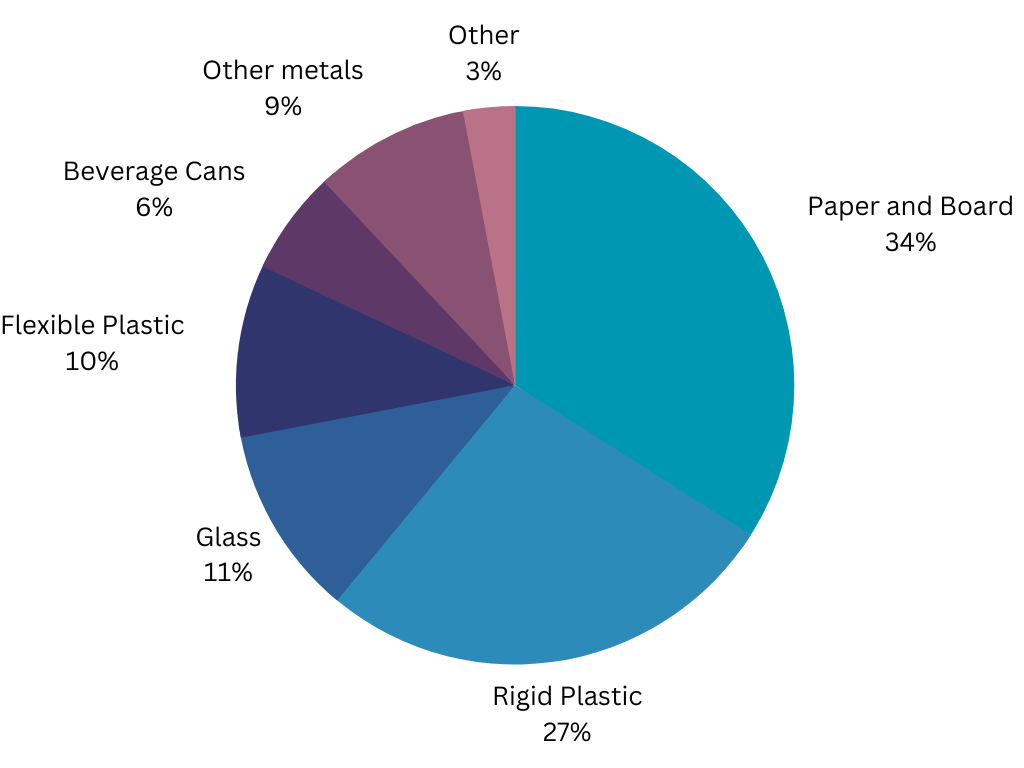

For 2012, the market share of packaging materials in food is presented in the pie chart below:

Figure 1: Food Packaging Materials. Source: Rexam Consumer Packaging Report 2011/2012.

What are the different materials that can be used for food packaging

The main materials used in food packaging are presented below:

Plastic in food packaging

Plastic is one of the most common materials used in food packaging. Its main advantages are that it is lightweight, versatile, and cost-effective. It can be used for packaging dry or wet/liquid food as it is moisture-resistant. The most used material is polyethylene (PE). Another widely used subtype of plastic is polyethylene terephthalate (PET). PET plastics are primarily used for soft drink bottles, covers for prep meals, fruit juice containers, cream jars, cooking oil and sauce bottles, wraps, and trays. The physical and chemical properties of these compounds make them acceptable to almost every food source.

Important factors to consider are that some plastics might be permeable to gases. Hence, they need additional layers to prevent oxygen penetration and do not react well with hot food.

Glass used in food packaging

Glass is another material used widely in the food industry. It does not react chemically with food, so it is considered one of the safest and most hygienic packing materials for human health. It can be used to pack anything dry, wet, and acidic. It is highly corrosion-resistant and safe for food. It can be used to preserve food long-term.

The main disadvantages are that glass containers and bottles are heavy and expensive compared to other materials. Additionally, they can easily break, which is a factor that might impact transportation costs.

Paper and cardboard used in food packaging

They are often used for packing dry and solid foods. They are low-cost, very lightweight materials, and it is easy to print the label on them. Additionally, they are recyclable, and recycled paper is often used in the packaging. Many times, coatings or laminates are added to improve the moisture resistance of the paper and cardboard packages.

The main disadvantages are that the paper is weak (can not hold heavy products), can not be used in wet food, and can be easily torn apart.

Ceramics used in food packaging

Ceramics are also used as a packaging material. Most of the time, it is cheaper than metal and glass packaging. Since they are non-corrosive and non-toxic, they can preserve the food quality. They are suitable for wet and dry products. If there are no extra layers, the raw material is biodegradable.

The main disadvantage of this product is that they have a limitation in sizes and shapes. Additionally, they can break easily and are not entirely safe for all food products.

Metals used in food packaging

Metals are also another alternative very commonly used for food packaging. It is an excellent barrier against oxygen, light, moisture, and pests. It is suitable for many wet/liquids or dry food items. It offers protection for the product during transportation and on the shelf. Additionally, it is recyclable. Like plastics, different types of metals are used in food packaging, such as tin, aluminum, and steel.

The main disadvantage of metals is that they are relatively expensive. The material is not flexible, so there is a limitation in the shapes used. Lastly, if no protective layers, such as lacquering, are being added, metals are prone to corrosion and react with certain food items (Alamri et al., 2021).

Biobased and Compostable Materials

Biobased materials are materials produced by microorganisms from renewables such as food waste, polysaccharides, or wood. For example, many people think that cellulose is a type of actual packaging while it is plant-based. Cellophane sheets and wraps are made using cellulose. Other types are biopolymers (bioplastics). Biodegradable materials, such as films, trays, and containers, are used in various food packaging applications. They help extend shelf life and reduce packaging waste, especially for short-lived, perishable items. Compostable materials are used for food packaging that can be disposed of along with food waste in composting systems. They contribute to nutrient-rich compost production and minimize the need for separate waste handling. (Agarwal et al., 2021)

Biobased materials are designed to degrade naturally, reducing environmental impact. Based on their synthesis, we can divide them into three groups.

Microbially originated materials are synthesized by fermentation methods. Examples are xanthan, dextrans, glucans, cellulose, poly (gamma-glutamic acid), hyaluronic acid, oligosaccharides, polysaccharides, and others.

Wood-based polymers are derived from lignocellulose. This category includes cellulose and hemicellulose, chitosan, chitin, and lignin.

Protein-based polymers are mainly materials such as gelatin and collagen, soy protein, and casein. Sometimes, protein-based (or lipid-based) materials can be used to create edible packaging. Edible packaging is made from materials that can be consumed along with food. This type of packaging can be found in edible films, coatings, and sachets. They are used mainly for single-serve portions and condiment packaging. Edible packaging can enhance sustainability and reduce waste.

In 2020, 2.11 million tonnes of bioplastics were produced, and 47% were used in the packaging industry.

How to Choose the Right Food Packaging Material?

There is often a debate on which raw materials to use for food packaging. Nowadays, many options have different properties, and deciding on the right one can be challenging.

Below, you can find some factors you should consider when choosing between various materials to package your product.

- Barrier properties regarding microorganisms, oxygen, light, moisture

- Food safety

- Sustainability

- Carbon footprint

- Costs to buy it and the costs for preparation and transportation

- Convenience and easiness for consumers

- Fully recyclable or not

- The shelf life of the product

References:

Agarwal, A., Shaida, B., Rastogi, M. et al. Food Packaging Materials with Special Reference to Biopolymers-Properties and Applications. Chemistry Africa 6, 117–144 (2023). https://doi.org/10.1007/s42250-022-00446-w

M.S. Alamri, Akram A.A. Qasem, Abdellatif A. Mohamed, Shahzad Hussain, Mohamed A. Ibraheem, Ghalia Shamlan, Hesham A. Alqah, Ali S. Qasha, 2021, Food packaging’s materials: A food safety perspective, Department of Food Science and Nutrition, King Saud University, P.O. Box 2460, Riyadh 11451, Saudi Arabia

European Commission, Food Safety, Food Contact Materials, https://food.ec.europa.eu/safety/chemical-safety/food-contact-materials_en#:~:text=Such%20materials%20and%20articles%20include,Food%20Contact%20Materials%20(FCMs).

G.L. Robertson, Food Packaging, Editor(s): Neal K. Van Alfen, Encyclopedia of Agriculture and Food Systems, Academic Press, 2014, Pages 232-249, ISBN 9780080931395, https://doi.org/10.1016/B978-0-444-52512-3.00063-2.

EFSA, Food Contact Materials, https://www.efsa.europa.eu/en/topics/topic/food-contact-materials