Manothermosonication: Revolutionizing Liquid Whole Egg Pasteurization with Enhanced Safety and Quality

Ultrasound (US) is becoming a popular technology in the food industry because it can enhance the taste, texture, and nutritional value of food while ensuring safety. However, using the US alone requires more power and longer treatment times than traditional heat treatments to effectively inactivate pathogenic microorganisms. To optimize the efficiency of ultrasound, it is often combined with other methods, such as gentle heating and elevated pressure treatments. Consequently, manothermosonication is one of the most promising combinations, and it is particularly effective for decontaminating food products like liquid eggs.

What is Manothermosonication (MTS)

Manothermosonication (MTS) as a potential alternative to food decontamination technologies was investigated to inactivate Salmonella enteritidis in liquid whole egg (LWE) pasteurization. This method was assessed as an alternative food decontamination technique, comparing its effectiveness and impact on LWE techno-functional properties with traditional thermal methods. Moreover, the research focused on modeling microbial inactivation kinetics under dynamic thermal conditions and evaluating the combined effects of ultrasound (US) and heat treatments. Finally, the study examined the functional properties of LWE after MTS treatment compared to conventional thermal pasteurization.

How Manothermosonication (MTS) works and how is applied to Liquid Whole Egg (LWE)

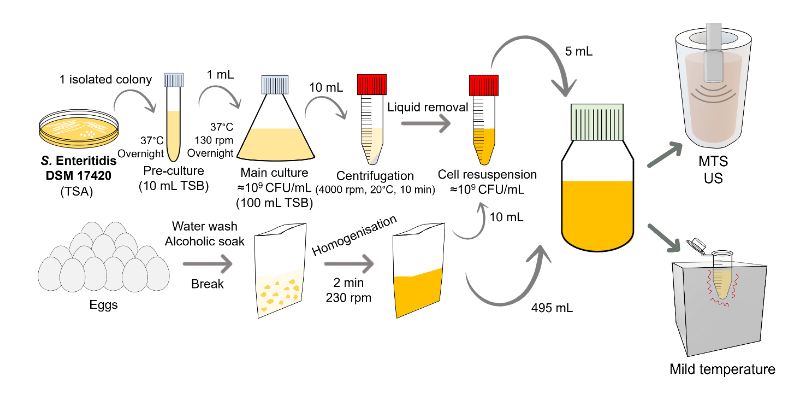

The study involved two main phases: inactivation studies (see Figure 1) and evaluation of techno-functional LWE properties (foaming, emulsifying, gelling, and protein properties). In the first phase, MTS processing conditions were evaluated to identify optimal settings for microbial inactivation, for that wave amplitude, pressure levels, and temperature increases were assessed to determine their effects on S. Enteritidis inactivation.

Figure 1 – Protocol followed for the preparation of the LWE suspensions used for the investigation of the inactivation of S. Enteritidis using inactivation treatments, including MTS.

Results and Discussion: Key Findings on Food Safety

Concerning food safety, key findings included:

- Wave amplitude: Higher wave amplitudes (132 μm) resulted in more effective microbial inactivation.

- Pressure: Elevated pressure levels (300 kPa) didn’t consistently yield the highest inactivation rates. However, a higher intensity (UI), which combines wave amplitude and pressure, caused rapid temperature increases that positively impacted microbial sensitization and inactivation.

- Temperature effects: The fast temperature increases due to higher UI levels led to significant microbial inactivation in shorter times.

From the experimental data, the log-linear model was used to estimate the kinetic parameters for MTS. Kinetic parameters used were the Dref (time to reduce the microbial population by one log at reference conditions), zT (temperature increase needed to reduce the D-value by one log), and zUI (ultrasound intensity increase needed to reduce the D-value by one log) values under dynamic temperature conditions at reference conditions of 57°C and 166.91 W/cm². Comparing the kinetic parameters estimated for each inactivation treatment, a synergistic lethal effect was found after MTS, meaning it was more effective at inactivating S. Enteritidis than using US or heat alone. The study also found that a kmax (maximum inactivation rate) of around 4 min⁻¹ could be achieved at 57°C and 277.56 W/cm², leading to rapid inactivation of Salmonella in LWE with short MTS treatments, then using these conditions to evaluate the LWE quality effects after MTS.

Techno-Functional Properties: Enhanced Quality with MTS

In a second step, the techno-functional properties in the LWE after MTS were investigated by comparing it with traditional thermal pasteurization (TT) at a constant 60°C. To achieve a 5-log reduction in S. Enteritidis, both methods required a processing time of 3.5 minutes. However, MTS reduced the thermal exposure of LWE, potentially preserving its functional properties better than conventional treatments. The results showed several benefits of MTS over traditional pasteurization:

- Foaming properties: MTS significantly improved the foaming capacity of LWE, achieving more than a 3.2-fold increase compared to TT. Foam stability also increased due to reduced viscosity, which exhibited pseudoplastic behaviour.

- Emulsion stability: MTS-treated LWE showed better emulsion stability with a wider droplet size distribution and smaller emulsion droplets. However, the overall emulsion capacity remained similar to untreated samples.

- Gelation properties: Although no differences in gelling temperatures were observed among the samples, MTS-treated LWE formed more elastic gels during gelation dynamic measurements.

- Protein properties: MTS caused favourable conformational changes in proteins, leading to higher protein unfolding without aggregation. This was evidenced by an increase in hydrodynamic radii of proteins other than ovalbumin, higher surface hydrophobicity, and increased free and total SH group contents. Additionally, MTS resulted in higher protein solubility compared to TT.

Conclusion: Manothermosonication (MTS) as a Promising Alternative for Pasteurization

The study demonstrated that MTS is a promising alternative to traditional pasteurization methods in LWE decontamination. It effectively inactivates S. Enteritidis while preserving and enhancing the functional properties of the eggs. MTS-treated LWE exhibited improved foaming and emulsion stability, better gelation dynamics, and favourable changes in protein structure and solubility. Implementing MTS in food processing could offer several benefits. It provides a more efficient and potentially safer method for LWE pasteurisation, reducing the thermal exposure that can decrease the functional properties. As a result, MTS-treated products might retain better quality and offer improved performance. Moreover, MTS could be investigated in other food products, expanding its utility in ensuring food safety and quality.

Further Reading

Non-thermal plasma (NTP) for the improvement of food safety and quality

The Impact of Strain Variability on the Inactivation Efficacy of Ultrasound Technology

Exploring Pulsed Electric Field (PEF) Microbial Inactivation for Food Processing

Understanding Consumer Perception in Food Product Development: Key to Market Success

Unlocking the Potential of High Hydrostatic Pressure: A Fresh Approach to Food Preservation

Using AI to evaluate non-thermal processing efficacy and assess the global impact

Safeguarding Your Plate: How High-Pressure Processing Enhances Food Safety and Quality