How Nanotechnology is used in the Food Industry

Nanotechnology in the Food Industry: An Upcoming Revolution

Key Takeaways

- Nano is a Greek word that means billionth of something. One nanometer equals one billionth of a meter.

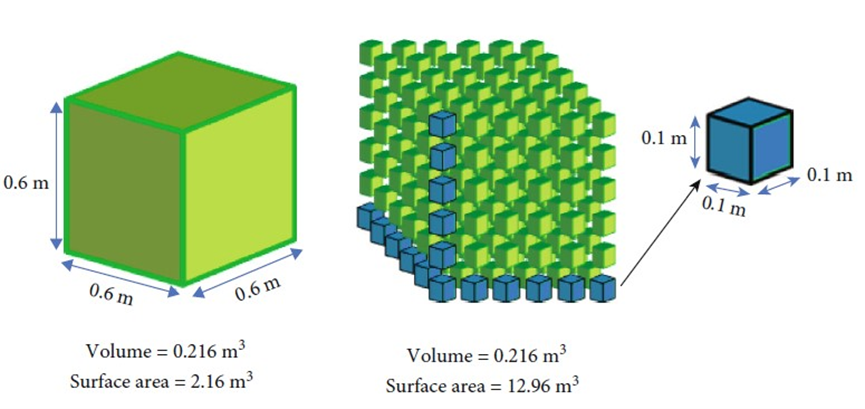

- Nanotechnology is an exciting new field with enormous promise across many industries, including the food sector, medicine, and mechanics. It is the study of controlling and manipulating matter at the atomic and molecular level, with at least one characteristic dimension measured in nanometers, often between 1 and 100 nm. As a subfield of Materials Science, Nanoscience and Nanotechnology encompasses the discovery, manufacturing, characterisation, modelling, and use of nanoscale materials. Figure A shows the surface area difference between the nanoparticle and the standard particle. Such high surface volume ratio nanoparticles can have outstanding physiochemical properties in terms of solubility, diffusivity, bioavailability, colour, optics, strength, intoxicity, magnetism, and thermodynamics.

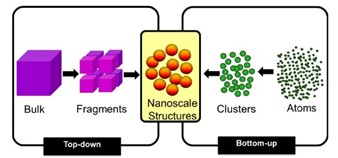

- The current article addresses the techniques for the synthesis of nanomaterials, as well as their classification. There are two ways to prepare nanomaterials: top-down and bottom-up methods. The top-down approach to nanoparticles includes a variety of physical and chemical treatments such as sonication, milling, and high-pressure homogenization. In the bottom-up technique, the building blocks of nanoparticles are generated first and assembled to produce the final particles.

- Nanomaterials are categorised according to their size, structure, and properties. Organic nanomaterials and inorganic nanomaterials are the two types of nanomaterials, respectively.

- Its applications in the food sector, the safety issues and regulatory aspects associated with nanotechnology will be reviewed in a future article.

Figure A. Surface area differences between bulk and nanoparticles*.

* Vijayakumar, M.D., Surendhar, G.J., Natrayan, L., Pravin, P., Patil, P. M., Bupathi, Ram, and Prabhu Paramasivam (2022) Review Article: Evolution and Recent Scenario of Nanotechnology in Agriculture and Food Industries. Journal of Nanomaterials (Hindawi), Volume 2022, Article ID 1280411, 17 pages, https://doi.org/10.1155/2022/1280411

Although nanotechnology is widely used in many industries, including agriculture, biochemistry, medicine, and many others, it is still a young subject that is more adaptable to novel and sophisticated applications in food systems than other technologies. It presents a workable plan for incorporating cutting-edge technology into a variety of functions associated with food production, development, fabrication, packaging, storage, and distribution. Nanoparticles, the most advanced technology in nano-based food science, deal with a variety of nanostructured materials and nano methods, including nanofood, nanotubes, nanocomposites, nano packaging, nanocapsules, nanosensors, liposomes, nanoemulsions, polymeric nanoparticles, and nanoencapsulation.. This method (NPs) is developed to increase food solubility and shelf life, availability of bioactive chemicals, the protection of food constituents, nutritional supplementation, fortification and food or constituent delivery. Additionally, it serves as an antibacterial agent by generating reactive oxygen species (ROS) which cause bacterial DNA damage, protein denaturation and cell damage. Although the use of nanotechnology in food applications is advancing, there are certain negative or dangerous effects on health related to the toxicity and dangers of ingesting nanoparticles in food (1). The use of nanotechnology in the food industry, notably in processing, preservation – food safety and packaging, with its promising future, will be addressed in a second article. The toxicity of nanoparticles in food as well as its development in food safety assessments with certain areas of concern will also be reviewed in a future text.

1. What is Nanotechnology?

1.1 Introduction to Nanotechnology

Nanotechnology is a rising revolution with enormous potential in fields ranging from mechanics to medicine, including the food business. It is the study of the manipulation and control of matter on an atomic and molecular scale, with at least one characteristic dimension in nanometres, which frequently ranges from 1 to 100 nm (2). It employs nanoscale materials and can develop unique devices and procedures. Nanoparticles are thought to be small objects that behave as a full unit, possessing distinct qualities and functions and initiating a new level of activity (3). Because of their increased surface area and mass transfer rates, nanoparticles appear to have more chemical and biological activity, enzymatic reactivity, penetrability, catalytic behaviour, and quantum characteristics than conventional particles (4). Such high surface volume ratio nanoparticles can have outstanding physiochemical properties in terms of solubility, diffusivity, bioavailability, colour, optics, strength, nontoxicity, magnetism, and thermodynamics (5).

1.2 How are nanomaterials synthesized?

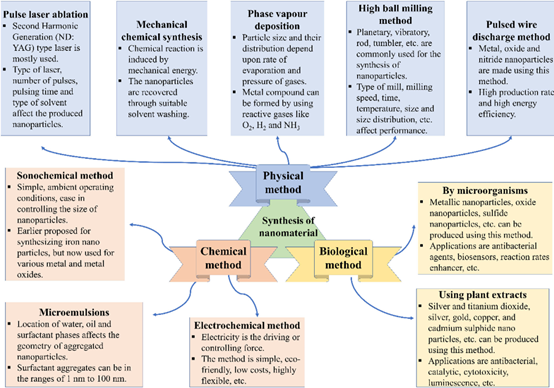

Different forms of nanomaterials can be created using a wide range of procedures including particles, colloids, thin films, tubes, rods, clusters, wires, powders, and more. These methods are categorised into three main techniques for creating a nanomaterial, as depicted in Figure 1. Quantum dots (QDs), nanowires, nanorods, and nanoplates are a few examples of the types of nanostructures that the method is built on (6).

Physical Method

In the physical method, mechanical forces and evaporation are generally utilized for the synthesis of nanomaterial. 1. Pulse laser ablation, 2. Mechanical/high ball milling method, 3. Wire discharge method, 4. Mechanical chemical synthesis, 5. Physical vapour deposition with consolidation, and so on are some physical methods used for the synthesis of nanomaterials (8).

Chemical Method

Chemical methods have some advantages over physical methods, such as simple techniques, low-temperature (350 oC) synthesis, the ability to create a wide range of nanoparticle sizes and shapes, easy conversion of the liquid end product to dry powder or thin films, the incorporation of foreign atoms (iron) during synthesis, and so on (9). Some of the chemical approaches are microemulsion/colloidal method, sonochemical method and electrochemical method.

Biological method

The biological approach of nanomaterial synthesis offers numerous advantages, including nontoxicity, easy scaling-up, reproducibility in manufacturing, well-defined morphology, eco-friendly methods, and so on. Some biological techniques for creating nanoparticles covered below are nanoparticle synthesis by microorganisms such as bacteria, fungus, yeasts, and so on, and nanoparticle synthesis by plant extracts (10).

- Nanoparticle synthesis by a microorganism

- Nanoparticle synthesis by plant extracts

Figure 1. Different methods for synthesis of nanomaterials (6).

1.3 How are nanomaterials classified?

According to Yu et al., 2018 (11), nanomaterials are classified as organic, non-organic, or even a combination of the two. Because organic nanomaterials are more naturally biodegradable than inorganic nanomaterials, they are used to creating bio-nanocomposites when mixed with biodegradable polymers. However, the use of inorganic nanomaterial as an antibacterial agent in food packaging systems is rather common. Depending on the type of inorganic nanoparticle, inorganic nanoparticles can be created via the sol-gel method, mechanochemical processing, physical vapour synthesis, and other methods (12).

Organic nanomaterials

Organic nanomaterials are made up of polymeric nanoparticles and lipid-based nanoparticles, and they are as follows:

- Polymeric nanoparticles

- Lipid-based nanocarriers

- Liposomes

- Solid lipid nanoparticles

- Carbon-based nanomaterials

Inorganic nanomaterials

Inorganic nanomaterials are made up of nanoparticles consisting of inorganic material and/or have metallic nanostructure such as QDs. The inorganic components utilized to create inorganic nanoparticles include silver, iron oxide, titanium dioxide, silicon dioxide, or zinc oxides. At room temperature, these particles can either be crystalline or amorphous solids with spherical or nonspherical shapes (13). These are used in food applications such as whitening agents, fortification, managing powder flowability, antimicrobial agents in food packaging, and so on (14).

1.4 Which methods are used in nanofabrication

The two methods for creating nanostructures and nanomaterials are top-down and bottom-up (15). Using milling, bulk materials are broken down to nanoscale in the top-down method. Bulk materials are mechanically ground, and the resulting nanosized particles are then stabilised by the addition of colloidal stabilising chemicals. The top-down method’s slow manufacturing rate, which makes it unsuitable for mass production, is its main drawback, albeit (16), (17). Other drawbacks include contaminations, internal stress introduction, and surface imperfections (i.e., blemishes). Additionally, this process involves material wastage, and it is constrained by the tool resolution. The construction of nanomaterials from individual atoms with the capacity to self-assemble in a natural and self-regulating manner is what distinguishes the bottom-up method from the top-down method (18) (Figure 2). It is more likely that the bottom-up method will result in nanostructures with fewer flaws, a more homogeneous chemical makeup, and superior short- and long-range ordering.

Figure 2. “Top-down” and “bottom-up” synthesis of nanofabrication (15)

2. Nanotechnology in the Food Industry

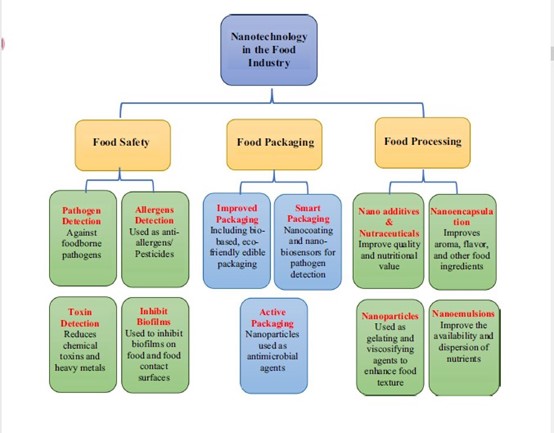

Similar to other industries, the food industry is relying heavily on nanotechnology as a potential technology for problem-solving via creative approaches to food safety – preservation, food processing, food packaging, and functional foods (Figure 3) (19), (20). Nanotechnology in food packaging has drawn the most attention due to the enhancement of food product quality and safety (19), (21). In this sense, nanotechnology can enhance food packaging, resulting in foods that are safer, healthier, and of a higher calibre with a longer shelf life (21), (22).

Figure 3. The application of nanotechnology in food safety, food packaging and food processing (8).

2.1 Nanostructured Materials – NSMs in Food

According to Pathakoti, Manubolu, and Hwang (2017) (23), nanostructured materials (NSMs) are microstructures made of nanoscale building blocks or structures that range in size from a few nanometers (typically 1-10) and can be developed into a variety of forms. NSMs fundamentally produce layered films, wires, and atomic structures and are mostly composed of nanorods, nanoparticles, nanowires, and other small objects. Three types of NSMs are distinguished:

- 0-dimensional for NPs, 1-dimensional nanorods or nanotubes,

- 2-dimensional for thin films

- 3-dimensional for nanocomposites and dendrimers.

According to Pathakoti et al. (2017) (23), these classifications are based on the dimension of structural elements.

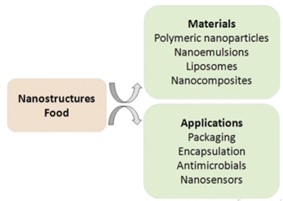

Many natural food ingredients are nano-sized and differ from man-made nanomaterials. Many food proteins have globular structures ranging in size from 10 nm to 100 nm, while most polysaccharides and lipids are linear polymers with a thickness of 1 nm (one-dimensional nanostructures). Milk and milk products, such as milk proteins and casein, are also natural nanostructures (23). Polymeric NPs, nanoemulsion, nanocomposites, and liposomes are the most significant nanostructures in food systems (Figure 4) as they improve bioavailability, protect bioactive ingredients, and assist controlled release (24).

Figure 4. Overview of nanostructures in food and their applications in food science (24).

An overview of these nanostructures is provided below:

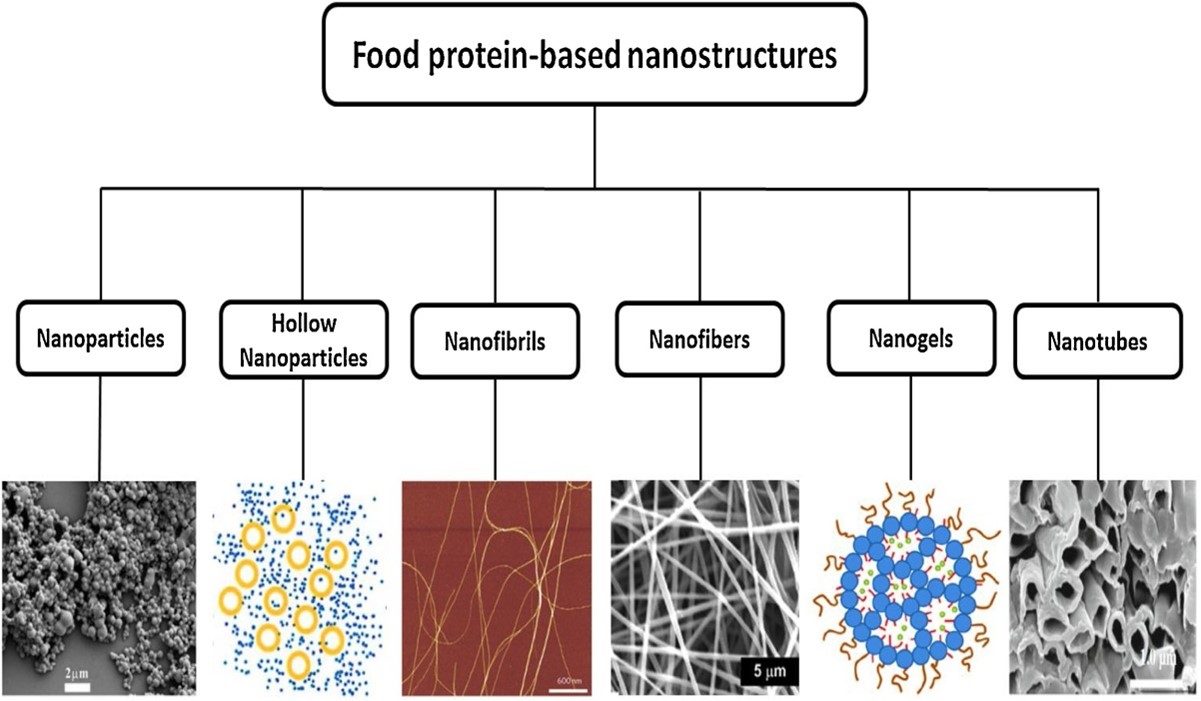

Biopolymeric nanostructured particles (proteins)

Many proteins have the capacity to contain bioactive components and form nano complexes (5-100 nm diameter micelles) due to the uniformity in their primary structure and the presence of primary amino groups necessary for bioactive component conjugation (25). Figure 5. shows how these proteins are classified into various structures, namely nanoparticles, hollow nanoparticles, nano-hydrogels, heat-induced nano fibrillar aggregates, electro spun nanofibres, and tubular nanostructures (26), (27). These nanostructured proteins have distinct functional and biological features that are relevant to food research and applications.

Figure 5. Different food protein-based nanocarriers (25)

These distinguishing characteristics are biocompatibility, biodegradability, surface activity, amphiphilic nature, film-forming ability, water-binding capacity, gelation, foaming, and emulsification (28). Several nanostructured proteins, including gelatin, zein, soy protein, β-lactoglobulin, gluten, silk fibroin, and milk proteins, have been utilised or researched for the preparation of various bioactive substances for use in food.

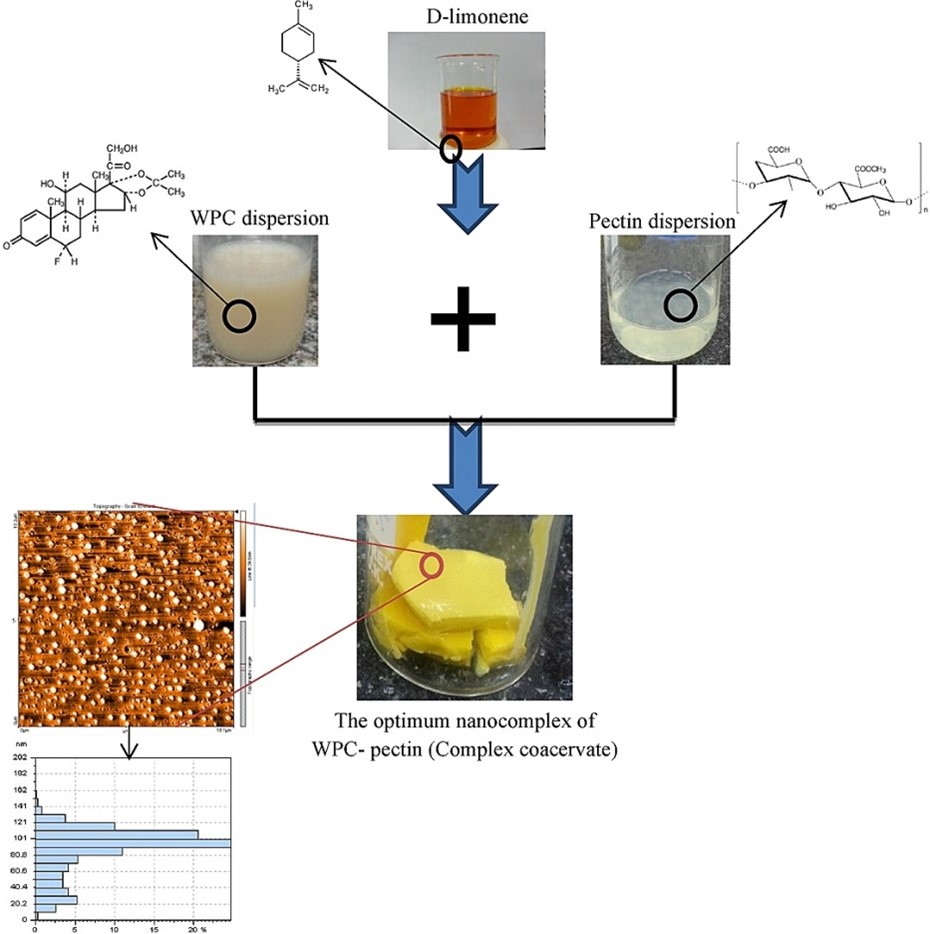

Figure 6. Nanoencapsulation of d-limonene within nanocarriers produced by pectin-whey protein complexes (29)

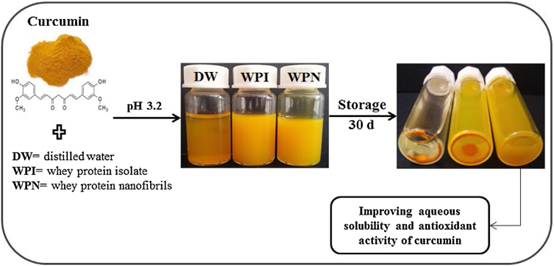

Figure 7. Whey protein nanofibrils as curcumin carriers (30)

It had been identified that:

- β-lactoglobulin (β-Lg) is a commonly utilized nano hydrogel for bioactive incorporation (29).

- Whey protein concentrate (WPC) has also been used to form nano complexes with pectin capable of encapsulating appreciable amounts of d-limonene (29). D-Limonene is one of the important flavours which is used extensively in the food industries, and it is extracted from citrus peels (Figure 6).

- whey protein nanofibrils (WPN) were used as carriers to improve the aqueous solubility of curcumin at acidic conditions (pH 3.2) for expanding its applications in functional beverages and drinks (31) (Figure 7).

- Food-grade bio nanopolymers can be created from nanostructured proteins, and polylactic acid (PLA) is the most commonly available and manufactured biodegradable nanopolymer and a popular eco-friendly coating material.

It is especially appealing in the domains of packaging, drug carriers, artificial blood vessels, and tissue engineering scaffolds since it is biodegradable, has excellent mechanical qualities, is affordable, and consistently performs when purchased from commercial sources (32). It is generally utilised for protein encapsulation and delivery, as well as medication and vaccine delivery. However, the fundamental restriction is that it is rapidly cleared from the bloodstream and gets deposited in the liver and kidneys. As a result, PLA requires polyethylene glycol as an associative ingredient in order to deliver active components (32).

Nanoemulsions

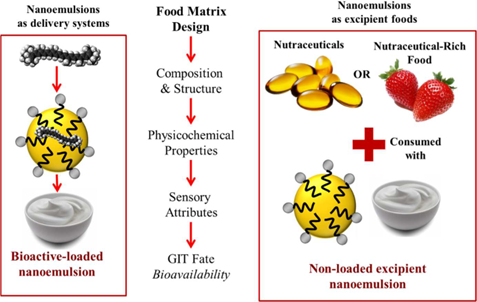

Nanoemulsions are another type of nanomaterial created by combining two or more difficult-to-combine liquids, such as oil and water. This type of mixing is known as an emulsion (12). Nanoemulsions are made up of droplets that are scattered and have a diameter of 500 nm or less. In food systems, emulsion applications are employed to transfer hydrophobic active compounds (33). Nanoemulsions are used for several food product applications such as for salad dressing, flavoured oils, sweeteners, personalized beverages and other food applications (34). The benefits of nanoemulsions include great clarity without sacrificing product look or flavour, as well as decontamination of equipment (6). Nanoemulsions with functional compounds are utilised to deliver co-enzyme Q10, Omega-3 fatty acids, vitamins (A, D, and E), lutein, lycopene, and –carotene (35). Furthermore, the active components in nanoemulsion formulations can be used to create biodegradable coating and packaging films in order to improve food quality and nutritional content while also extending shelf life. Incorporating a functional food component in the droplets (36) delays the chemical breakdown process by modifying the interfacial layer properties (37). In another research, the use of excipient nanoemulsions for increasing the bioavailability of bioactive components from fruits and vegetables is described (38). For this application, nanoemulsions have a number of benefits over other food systems, including the capacity to integrate excipient components that are hydrophilic, amphiphilic, and lipophilic, high physical stability, and rapid gastrointestinal digestibility. Excipient foods, which often lack functionality themselves, have the power to improve the functionality of nutrients found in natural foods by changing how easily those nutrients are absorbed, bioaccessibly, and/or chemically transformed. Excipient foods are divided into two categories: (i) integrated excipient foods, in which the bioactive agents are distributed throughout the excipient food formulation; (ii) non-integrated excipient foods, in which a bioactive-rich food is consumed alongside an excipient food formulation (Figure 8). Nanoemulsions have a huge surface area due to their small droplet size and can therefore interact significantly with biological elements in the GIT. For instance, since nanoemulsions have more binding sites available for digestive enzymes like lipase, they typically dissolve more quickly in the gastrointestinal tract than conventional emulsions (39). Furthermore, the small droplet size may facilitate the rapid transfer of naturally occurring hydrophobic bioactives found in meals into the oil droplets.

Figure 8. A diagram depicting the distinction between integrated and non-integrated excipient foods. The bioactive component (pharmaceutical or nutraceutical) is dispersed inside the excipient food matrix in integrated excipient foods, whereas in non-integrated excipient foods, the bioactive component is in another product that is co-ingested with the excipient food (38).

Nanocomposites – Nanolaminates

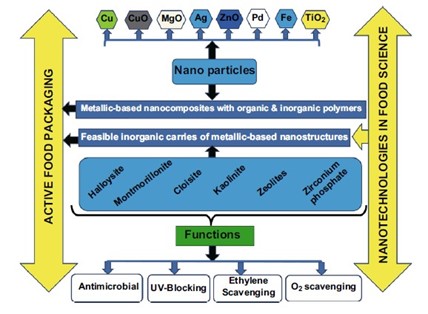

In addition to nanoparticles, nanocomposites and nanolaminates have a wide range of applications in food packaging ,and they have been widely employed in antimicrobial packaging of food items in recent years. Nanocomposite food packaging constructed of polymers is one of the best alternatives to traditional packaging systems (paper, glass, and metals) because it is a low-cost and high-functional solution (40). Polymer matrices are reinforced with nanofillers (nano oxides, nano clays, cellulose microfibrillis, and carbon nanotubes) to create nanocomposites with at least one phase dimension less than 100 nm (41) (Figure 9). Nanocomposites are primarily used to protect foods from mechanical and high-temperature shock, as well as to extend their shelf life (42). Nanoclay consists of layered mineral silicates with layered structural units that can be stacked to generate intricate clay crystallites (43). Furthermore, nanoclays are classified into several classes based on their shape and chemical content, including montmorillonite, bentonite, smectite, chlorite, illite, kaolinite, hectorite, and halloysite (43). Moreover, nano clays are readily available, inexpensive, and environmentally beneficial. As a result, their applications have been researched and broadened in a variety of fields (43). In the food industry, for example, nano clay is commonly used in food packaging because it has a natural nanolayer structure that works as a barrier for gas and moisture (12). Nanolaminates are frequently synthesised from proteins, lipids, and polysaccharides, and their uses include packaging materials and other food-related applications. Nanolaminates, for example, may be utilised as edible coatings and films on a variety of food products such as vegetables, fruits, meats, candies, chocolates, and bakery goods. In this situation, coatings or films could serve as a barrier for moisture, gas, and lipids. Furthermore, nanolaminates can be employed as functional component carriers, such as flavours, colours, antibacterial chemicals, and antioxidants (12). In addition to this and in response to global environmental issues and concerns, the demand for biodegradable packaging materials (PLA, polyvinyl alcohol, polyglycolic acid) is growing.

Figure 9. Potential for the development of metallic-based nanocomposites in active food packaging (44)

Nanoliposomes – Tocosomes

Nanoscale lipid bilayers, also known as nanoliposomes, are spherical vesicles generated by the dispersion of phospholipid molecules in a water-based media by energy input. The other nanoscale entity addressed in this entry, the tocosome, is a recently introduced bioactive carrier consisting primarily of tocopheryl phosphates. These nanocarriers can carry hydrophilic and hydrophobic material independently or simultaneously due to their bi-compartmental structure, which includes lipidic and aqueous compartments. Nanoliposomes and tocosomes can protect and release sensitive food-grade bioactive compounds over time. They are used to encapsulate various bioactive components (such as medicines, vaccines, antimicrobials, antioxidants, minerals, and preservatives), as well as to enhance and fortify various food and nutraceutical compositions.

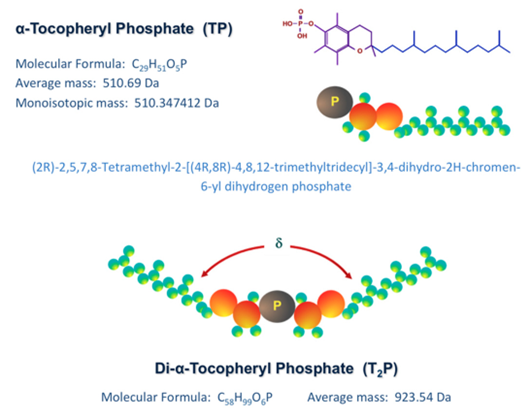

Figure 10. Alpha tocopheryl phosphate (TP) and di-alpha tocopheryl phosphate (T2P) chemical structures. The angle of alignment of the T2P molecule’s hydrocarbon chains (phytyl tails) (δ) leads to an “inverted truncated cone” molecule with a critical packing parameter (cpp) greater than 1

The cylindrical-shaped PC molecule aggregates into bilayer planar sheets, minimizing the thermodynamically undesirable interactions between the bulk aqueous phase and the hydrocarbon chains (and therefore lowering the energy level) (46). This energy-minimization results in the bilayer membrane internalizing any hydrophobic substance in the aqueous environment.

Tocopherols with phosphate groups are the major building materials of tocosomes, which are colloidal and vesicular bioactive carrier systems (47). They can, however, accomodate sterols, proteins, and polymers in their structure, just as nanoliposomes. Alpha-tocopherol phosphate (TP), a phosphorylated version of alpha-tocopherol, is found naturally in human and some animal tissues and certain dietary molecules (48). A phosphate group is linked to one hydrophobic chain (phytyl tail) formed of three isoprene units to form TP. T2P, a phytyl chain-containing molecule similar to TP, is made up of two phytyl chains. T2P’s hydrophobic phytyl chains, unlike those of phosphatidylcholine and other phospholipids, cannot align in parallel due to the presence of bulky isoprene side chains (Figure 10). As a result, the geometric shape of the T2P molecule is conical, whereas the TP molecule is cylindrical (similar to the PC molecule).

Clinical studies have revealed that TP and T2P molecules have numerous health benefits, including anti-inflammatory, atherosclerotic-preventing, and cardioprotective capabilities (49), (50). Furthermore, the inhibitory effect of the TP molecule on tumour invasion has been demonstrated (51). As discussed in the above paragraphs, tocosomes have a high potential for use in the formulation of food and nutraceutical products due to their unique combination of compounds with exceptional health benefits and strong antioxidant activity.

The food and diet sectors have witnessed less development of nanoliposome and tocosome technologies than the pharmaceutical and cosmetics industries. Despite this, the agri-food business is thought to have the most potential uses for nanobiotechnology (52). The limited advancement to date has not been owing to a lack of possible uses, but rather to difficulties in discovering safe, low-cost ingredients and cost-effective processing technologies suited for creating large volumes of nanoliposomes/tocosomes with batch-to-batch consistency. Using tocosomes and nanoliposomes as potential carriers for encapsulating and delivering food components and nutraceutical substances is a relatively innovative technology. So far, research has shown that carrier systems have the potential to improve the flavour of ripened cheese using accelerated methods, to deliver functional food ingredients in a targeted manner, to deliver tocopherols and ascorbic acid synergistically for enhancing antioxidant activities in foods, and to stabilise minerals such as calcium and iron in milk and other beverages (53). They also served as good candidates for entrapping and delivering antimicrobial agents to extend product shelf life (45).

You can read also:

How nanotechnology is used in agriculture

References:

- Biswas, R., Alam, M., Sarkar, A., Haque, I. Md., Hasan, M. (Md), Hoque, M., (2022) Application of nanotechnology in food: processing, preservation, packaging and safety assessment. Heliyon, 8, e1 1795. https://doi.org/10.1016/j.heliyon.2022.e11795

- Chellaram, C., Murugaboopathi, G., John, A. A., Sivakumar, R., Ganesan, S., Krithika, S., & Priya, G. (2014). Significance of nanotechnology in food industry. APCBEE Procedia, 8, 109–113

- Ozimek, L., Pospiech, E., & Narine, S. (2010). Nanotechnologies in food and meat processing. ACTA Scientiarum Polonorum Technologia Alimentaria, 9(4), 401–412.

- Avella,M., Bruno, G., Errico, M. E., Gentile, G., Piciocchi, N., Sorrentino, A., & Volpe, M. G. (2007). Innovative packaging for minimally processed fruits. Packaging Technology and Science, 20, 325–335. https://doi.org/10.1002/pts.761

- Avella, M., De Vlieger, J. J., Errico, M. E., Fischer, S., Vacca, P., & Volpe, M. G.(2005). Biodegradable starch/clay nanocomposite films for food packaging applications. Food Chemistry, 93, 467–474. https://doi.org/10.1016/j.foodchem.2004.10.024

- Sahoo, M., Vishwakarma, S., Panigrahi, C., Kumar, J. (2021) Nanotechnology: Current applications and future scope in food. Food Frontiers. 2:3–22. https://doi.org/10.1002/fft2.58

- Satyanarayana, T., & Reddy, S. S. (2018) A review on chemical and physical synthesis methods of nanomaterials. International Journal for Research in Applied Science & Engineering Technology, 6, 2885–2889. https://doi.org/10.22214/ijraset.2018.1396

- Zahra, H. M., Faizan, A., Salam, I. A., Sadaf, Z., (2022) Application of nanotechnology in different aspects of the food industry (Review). Discover Food. 2:12. https://doi.org/10.1007/s44187-022-00013-9

- Kulkarni, S. K. (2015b). Synthesis of nanomaterials—II (Chemical methods). In S. K. Kulkarni (Ed.), Nanotechnology: Principles and Practices (pp. 77–109). Cham: Springer. https://doi.org/10.1007/978-3-319-09171-6

- Singh, H. (2016) Nanotechnology applications in functional foods; opportunities and challenges. Preventive Nutrition and Food Science, 21 (1), 1–8. https://doi.org/10.3746/pnf.2016.21.1.1

- Yu, H., Park, J. Y., Kwon, C.W., Hong, S. C., Park, K. M., & Chang, P. S. (2018). An overview of nanotechnology in food science: Preparative methods, practical applications, and safety. Journal of Chemistry, 5427978, 1–10. https://doi.org/10.1155/2018/5427978

- Saxena, D C, and Bhardwaj, M. (2017) Development of Organic and Inorganic Nanoparticles and Their Subsequent Application in Nanocomposites for Food and Non-Food Packaging Systems, Nanoscience and Nanotechnology, Dubai, UAE, October 16-17, Dubai, UAE: Journal of Nanomedicine &Nanotechnology. https://doi.org/10.4172/2157-7439-C1-052

- McClements, D. J., & Xiao, H. (2012) Potential biological fate of ingested nanoemulsions: Influence of particle characteristics. Food & Function, (3), 202–220.

- Ariyarathna, I. R., Rajakaruna, R. M. P. I., & Karunaratne, D. N. (2017) The rise of inorganic nanomaterial implementation in food applications. Food Control, 77, 251–259. https://doi.org/10.1016/J.FOODCONT.2017.02.016

- Rawat, R.S. (2015) Dense Plasma Focus – From Alternative Fusion Source to Versatile High Energy Density Plasma Source for Plasma Nanotechnology. Journal of Physics Conference Series, 591(1):012021, https://doi.org/10.1088/1742-6596/591/1/012021

- Hsieh, Y. H. P, Ofori, J.A. (2007) Innovation in food technology for health. Asia Pac J Clin Nutr 16 (Suppl 1) 65-73. PMID: 17392079

- Moraru, C.I, Panchapakesan, C.P, Huang, Q., Takhistov, P., Liu, S., Kokini, J.L. (2003) Nanotechnology: a new frontier in food science. Food Technol 57:24-9. Available online at: https://www.ift.org/news-and-publications/food-technology-magazine/issues/2003/december/features/nanotechnology-a-new-frontier-in-food-science (assessed July 2023)

- Sanguansri, P., Augustin, M.A. (2006) Nanoscale materials development: a food industry perspective. Trends Food Sci Technol 17:547-56. https://doi.org/10.1016/j.tifs.2006.04.010

- Grumezescu AM, Holban AM, editors. (2018) Impact of nanoscience in the food industry, vol. 12. London: Academic Press; 2018.

- Chaudhry Q, Watkins R, Castle L. (2017) Nanotechnologies in food: what, why and how? In: Nanotechnologies in food. Cambridge: Royal Society of Chemistry.

- https://doi.org/10.1039/9781782626879-00001

- Colica C, et al. (2018) The role of nanotechnology in food safety. New York: Nova Science Publisher’s, Inc.

- Bajpai VK, et al. (2018) Prospects of using nanotechnology for food preservation, safety, and security. J Food Drug Anal. 2018; 26 (4):1201–14. https://doi.org/10.1016/j.jfda. 2018.06.011

- Pathakoti, K., Manubolu, M., & Hwang, H. M. (2017) Nanostructures: Current uses and future applications in food science. Journal of Food and Drug Analysis, 25(2), 245–253. https://doi.org/10.1016/j.jfda.2017.02.004

- Chang, Y. C., & Chen, D. H. (2005) Adsorption kinetics and thermodynamic of acid dyes on a carboxymethylated chitosan-conjugated magnetic nano-adsorbent. Macromolecular Bioscience, 5 (3), 254–261. https://doi.org/10.1002/mabi.200400153

- Mohammadian, M., Waly, M. I., Moghadam, M., Emam-Djomeh, Z., Salami, M., & Moosavi-Movahedi, A. A. (2020) Nanostructured food proteins as efficient systems for the encapsulation of bioactive compounds. Food Science and Human Wellness, 9(3), 199–213. https://doi.org/10.1016/j.fshw.2020.04.009

- Chang, Y. C., & Chen, D. H. (2005) Adsorption kinetics and thermodynamics of acid dyes on a carboxymethylated chitosan-conjugated magnetic nano-adsorbent. Macromolecular Bioscience, 5 (3), 254–261. https://doi.org/10.1002/mabi.200400153

- Fathi, F. Donsi, D.J. McClements (2018) Protein-based delivery systems for the nanoencapsulation of food ingredients, Compr. Rev. Food Sci. Food Saf. 17:920–936, http://dx.doi.org/10.1111/1541-4337.12360

- Abaee, A., Mohammadian, M., & Jafari, S. M. (2017) Whey and soy protein-based hydrogels and nano-hydrogels as bioactive delivery systems. Trends in Food Science & Technology, 70, 69–81. https://doi.org/10.1016/j.tifs.2017.10.011

- Ghasemi, S., Jafari, S.M., Assadpour, E., Khomeiri, M. (2018) Nanoencapsulation of d-limonene within nanocarriers produced by pectin-whey protein complexes. Food Hydrocoll. 77, 152–162. https://doi.org/10.1016/j.foodhyd.2017.09.030

- Mohammadian, M., Salami, M., Momen, S., et al. (2019) Enhancing the aqueous solubility of curcumin at acidic condition through the complexation with whey protein nanofibrils, Food Hydrocoll. 87:902–914, http://dx.doi.org/10.1016/j.foodhyd.2018.09.001

- Ritzoulis, C., Scoutaris, N., Papademetriou, K., Stavroulias, S., & Panayiotou, C. (2005) Milk protein-based emulsion gels for bone tissue engineering. Food Hydrocolloids, 19 (3), 575–581. https://doi.org/10.1016/j.foodhyd.2004.10.021

- Chen, G., Chen, Y., Jin, N., Li, J., Dong, S., Li, S., Zhang, Z., Chen, Y. (2020) Zein films with porous polylactic acid coatings via cold plasma pre-treatment. Industrial Crops and Products, Volume 150, 112382. https://doi.org/10.1016/j.indcrop.2020.112382

- Aswathanarayan, J. B, Vittal, R.R. (2019) Nanoemulsions and their potential applications in food industry. Front Sustain Food Syst. 3:95. https://doi.org/10.3389/fsufs.2019.00095

- Garti, N. (Ed.). (2008). Delivery and controlled release of bioactives in foods and nutraceuticals. Amsterdam, the Netherlands: Elsevier.

- Choi, A. J., Kim, C. J., Cho, Y. J., Hwang, J.K.,& Kim, C. T. (2011). Characterization of capsaicin-loaded nanoemulsions stabilized with alginate and chitosan by self-assembly. Food and Bioprocess Technology, 4(6), 1119–1126. https://doi.org/10.1007/s11947-011-0568-9

- Mc Clements, D. J., & Decker, E. A. (2000). Lipid oxidation in oil-in-water emulsions: Impact of molecular environment on chemical reactions in heterogeneous food systems. Journal of Food Science, 65(8), 1270–1282. https://doi.org/10.1111/j.1365-2621.2000.tb10596

- Gu, Y. S., Decker, A. E., & Mc Clements, D. J. (2005). Production and characterization of oil-in-water emulsions containing droplets stabilized by multilayer membranes consisting of β-lactoglobulin, ι-carrageenan and gelatin. Langmuir, 21(13), 5752–5760. https://doi.org/10.1021/la046888c

- Salvia-Trujillo, L., Martín-Belloso, O., Mc Clements, D.J (2016) Excipient Nanoemulsions for Improving Oral Bioavailability of Nanomaterials, 6(1), 17; https://doi.org/10.3390/nano6010017

- Salvia-Trujillo, L., Qian, C., Martín-Belloso, O., Mc Clements, D.J. (2013) Influence of particle size on lipid digestion and β-carotene bioaccessibility in emulsions and nanoemulsions. Food Chem. 141, 1472–1480. https://doi.org/10.1016/j.foodchem.2013.03.050

- Silvestre, C., Duraccio, D., & Cimmino, S. (2011). Food packaging based on polymer nanomaterials. Progress in Polymer Science, 36 (12), 1766–1782. https://doi.org/10.1016/j.progpolymsci.2011.02.003

- Bastarrachea, L., Dhawan, S., & Sablani, S. S. (2011). Engineering properties of polymeric-based antimicrobial films for food packaging: A review. Food Engineering Reviews, 3 (2), 79–93. https://doi.org/10.1007/s12393-011-9034-8

- Honarvar, Z, Hadian, Z, Mashayekh, M. (2016) Nanocomposites in food packaging applications and their risk assessment for health. Electron Physician. 8(6):2531. https://doi.org/10.19082/2531

- Guo, F, et al. (2018) A review of the synthesis and applications of polymer–nanoclay composites. Appl Sci. 8(9):1696. https://doi.org/10.3390/app8091696

- Nile, S.H., Baskar, V., Selvaraj, D. et al. (2020) Nanotechnologies in Food Science: Applications, Recent Trends, and Future Perspectives. Nano-Micro Lett. 12, 45. https://doi.org/10.1007/s40820-020-0383-9

- Zarrabi, A., Abadi, M.A.A., Khorasani, S., Mohammadabadi, M.R., Jamshidi, A., Torkaman, S., Taghavi, E., Mozafari, M.R., and Rast, B. (2020) Nanoliposomes and Tocosomes as Multifunctional Nanocarriers for the Encapsulation of Nutraceutical and Dietary Molecules. Molecules, 25, 638, https://doi.org/10.3390/molecules25030638

- Edris, A.E. (2012) Formulation and shelf life stability of water-borne lecithin nanoparticles for potential application in dietary supplements field. Diet. Suppl. 9, 211–222, https://doi.org/10.3109/19390211.2012.708717

- Mozafari, M.R.; Javanmard, R.; Raji, M. (2017) Tocosome: Novel drug delivery system containing phospholipids and tocopheryl phosphates. J. Pharm. 528, 381–382, https://doi.org/10.1016/j.ijpharm.2017.06.037

- Azzi, A. (2006) Tocopheryl phosphate, a novel natural form of vitamin E: In vitro and in vivo studies. FASEB J. 20, LB79 – LB80.

- Munteanu, A., Zingg, J.M., Ogru, E., Libinaki, R., Gianello, R., West, S., Azzi, A. (2004) Modulation of cell proliferation and gene expression by tocopheryl phosphates: Relevance to atherosclerosis and inflammation. Biophys. Res. Commun. 318, 311–316. https://doi.org/10.1196/annals.1331.058

- Libinaki, R., Tesanovic, S., Heal, A., Nikolovski, B., Vinh, A., Widdop, R.E., Ogru, E. (2010) Effect of tocopheryl phosphate on key biomarkers of inflammation: Implication in the reduction of atherosclerosis progression in a hypercholesterolaemic rabbit model. Exp. Pharmacol. Physiol. 37, 587–592. https://doi.org/10.1111/j.1440-1681.2010.05356.x

- Saitoh, Y., Yumoto, A., Miwa, N. (2009) Tocopheryl phosphate suppresses tumor invasion concurrently with dynamic morphological changes and delocalization of cortactin from invadopodia. J. Oncol. 35, 1277–1288. https://doi.org/10.3892/ijo_00000445

- Verma, M.L. (2017) Nanobiotechnology advances in enzymatic biosensors for the agri-food industry. Chem. Lett. 15, 555–560. https://doi.org/10.3892/ijo_00000445

- Khanniri, E., Bagheripoor – Fallah, N., Sohrabvandi, S. Mortazavian, A.M., Khosravi – Darani, K.(2016) Mohammad, R. Application of liposomes in some dairy products. Rev. Food Sci. Nutr. 56, 484–493. https://doi.org/10.1080/10408398.2013.779571