Harnessing pulsed power to enhance food safety and quality: Risks and benefits of pulsed electric field (PEF) technology

What is pulsed electric field (PEF) technology?

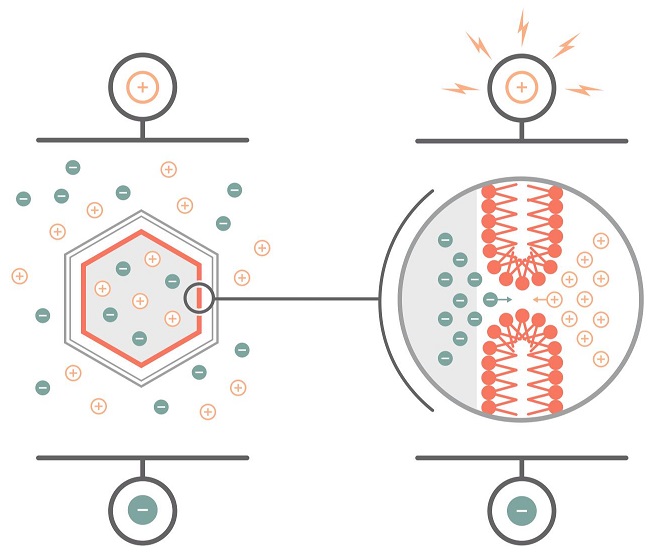

Pulsed electric field (PEF) is a technique that applies high-voltage electrical pulses to biological samples positioned between electrodes. Subjecting the sample to such a process essentially alters the permeability of the cell membrane via pore formation, a phenomenon also known as electroporation. Depending on the intensity of the applied electric field strength, electroporation may be reversible as the membrane reseals, whereas, after irreversible electroporation, the cell will lose its viability. Electroporation is not a new technique. Scientists have used it in the laboratory, for instance, to transfer genetic materials into a bacterial cell. By applying these same principles to human cells, electroporation also finds use in medical fields such as gene therapy, cancer treatment, drug delivery, and much more.

How PEF works

How is PEF currently used in the food industry?

Thanks to the development of powerful pulse generators, PEF can also be used on a very large scale to process plant materials designated for food production. For instance, applying low-intensity PEF to potatoes and root vegetables could result in a tissue-softening effect. The PEF-treated materials are typically more flexible, making them easier to cut and bend into new shapes. Other benefits of PEF application in the potato industry include yield improvement, reduced oil uptake during frying, and crispier texture (1). Moreover, PEF can also be applied to fruit and vegetables before dehydration. As PEF opens pores in the membrane, it creates a passage that allows faster water movement out of the tissue. At the same time, PEF has no effect on the cell wall, meaning that the plant tissue structure is preserved. Consequently, the drying time could be reduced, while the quality of the final product could be improved after applying PEF (2,3).

There is also a large body of emerging research indicating the potential benefits of PEF in the production of wine and olive oil. For example, the PEF pretreatment of olive mash could result in oils with higher phenolic contents (4), while the pretreatment of grapes could reduce maceration time, increase the color intensity of red wines, and improve the volatile composition of grapes must derive from certain varieties (5,6).

How can PEF be used as an alternative to thermal pasteurization?

Another possible application of PEF in the food industry is the preservation of food products through microbial decontamination. In this case, the targets of PEF are the microorganisms that cause spoilage and foodborne illnesses. There are different considerations when PEF is used for shelf-life extension purposes.

First, the intensity of the applied pulses must be high enough to cause irreversible electroporation, leading to microbial inactivation. To create a high electric field strength, it is necessary that the distance between the electrodes remains very small. This, in turn, limits the type of food that can be treated to mainly pumpable liquids and purees.

Secondly, the food matrix’s intrinsic properties will influence the process’s effectiveness. For instance, the low pH level can act as an additional hurdle against microbial growth in high-acid beverages like citrus fruit juices. In theory, the PEF treatment could be applied at a relatively lower intensity for such products. The electrical conductivity is another product-related parameter that must be assessed prior to deciding whether PEF is a suitable technique.

Finally, it will be critical to know the type of microbial contaminants found in the raw materials and how they may evolve throughout the processing steps to become the semi-finished product prior to the decontamination step. If PEF were to be used as a food safety control point, then the target must be the most PEF-resistant pathogen present.

The PEF pasteurization alternative protects the quality and nutritional value of foods.

Typically, the treatment duration of PEF is in the microseconds range, which is faster than most standard heat processes. More importantly, since the main target of PEF is the cell membrane, there is usually minimal impact on the heat-sensitive components of food, such as protein, vitamins, phytochemicals, and flavor compounds.

Compared to the thermally processed counterparts, products treated with PEF retain their fresh-like characteristics. The use of PEF for microbial decontamination has been studied in several liquid food products, including fruit and vegetable juices, dairy milk, liquid eggs, and wine (7–11). More recently, the application has also been studied in plant-based dairy alternatives, in line with the growing popularity of this product category (12–15).

Are there any risks associated with the PEF technique used in foods?

Unlike thermal processing, where the main process parameters are temperature and time, several other parameters can influence the efficacy of PEF. Some parameters are pulse shape, width, frequency, specific energy, and inlet temperature. Extensive personnel training could help overcome the initial learning curve and enable any business to benefit fully from PEF technology.

Due to the direct contact between the electrodes and the food product, some electrochemical reactions may occur during PEF processing. Depending on the applied intensity and composition of the food, this may lead to a release of electrode material and/or secondary reactions that produce undesirable toxic compounds (16). Nevertheless, strategies exist that help minimize and/or avoid these adverse chemical effects, including utilizing shorter-duration pulses and selecting electrode materials with higher resistance to electrochemical reactions (16).

It should be noted that PEF does not produce a lethal effect on bacterial spores at near-ambient temperatures. If spore inactivation is the goal, then PEF must be combined with another process, such as heating. PEF is often viewed as a possible alternative to pasteurization and will not render the products shelf-stable (as would be the case for sterilization). In other words, products that are PEF-treated still require refrigerated storage.

The process is also not a means to replace good manufacturing and proper sanitation practices or to lower the standards for supplier qualification. The integration of PEF into a production line implies that, as a microbial control strategy, it must be able to eliminate or at least minimize the risk of foodborne illnesses and product recalls. Successful implementation of the technology will require a continuous monitoring approach, as well as clearly laid out plans involving corrective and preventative actions in the event of equipment or process failures.

References

- Hill K, Ostermeier R, Töpfl S, Heinz V. Pulsed Electric Fields in the Potato Industry. In: Raso J, Heinz V, Alvarez I, Toepfl S, editors. Pulsed Electric Fields Technology for the Food Industry: Fundamentals and Applications [Internet]. 2nd ed. Cham, Switzerland: Springer Nature Switzerland AG; 2022. p. 325–35. Available from: https://link.springer.com/10.1007/978-3-030-70586-2_9

- Lammerskitten A, Wiktor A, Mykhailyk V, Samborska K, Gondek E, Witrowa-Rajchert D, et al. Pulsed electric field pre-treatment improves microstructure and crunchiness of freeze-dried plant materials: Case of strawberry. Lwt [Internet]. 2020;134(September):110266. Available from: https://doi.org/10.1016/j.lwt.2020.110266

- Lammerskitten A, Mykhailyk V, Wiktor A, Toepfl S, Nowacka M, Bialik M, et al. Impact of pulsed electric fields on physical properties of freeze-dried apple tissue. Innovative Food Science and Emerging Technologies. 2019;57(August).

- Puértolas E, Martínez De Marañón I. Olive oil pilot-production assisted by pulsed electric field: Impact on extraction yield, chemical parameters and sensory properties. Food Chem. 2015;167:497–502.

- Ricci A, Parpinello GP, Versari A. Recent advances and applications of pulsed electric fields (Pef) to improve polyphenol extraction and color release during red winemaking. Vol. 4, Beverages. MDPI AG; 2018.

- González-Arenzana L, Reinares JP, López N, Santamaría P, Garde-Cerdán T, Gutiérrez AR, et al. Impact of Pulsed Electric Field Treatment on Must and Wine Quality. In: Handbook of Electroporation. Springer International Publishing; 2016. p. 1–16.

- Timmermans RAH, Nierop Groot MN, Nederhoff AL, van Boekel MAJS, Matser AM, Mastwijk HC. Pulsed electric field processing of different fruit juices: Impact of pH and temperature on inactivation of spoilage and pathogenic micro-organisms. Int J Food Microbiol. 2014 Mar 3;173:105–11.

- Delso C, Berzosa A, Sanz J, Álvarez I, Raso J. Microbial Decontamination by Pulsed Electric Fields (PEF) in Winemaking. In: Grapes and Wine [Working Title] [Internet]. IntechOpen; 2021. Available from: https://www.intechopen.com/online-first/microbial-decontamination-by-pulsed-electric-fields-pef-in-winemaking

- Monfort S, Gayán E, Saldaña G, Puértolas E, Condón S, Raso J, et al. Inactivation of Salmonella Typhimurium and Staphylococcus aureus by pulsed electric fields in liquid whole egg. Innovative Food Science and Emerging Technologies. 2010 Apr;11(2):306–13.

- Akin E, Evrendilek GA. Effect of pulsed electric fields on physical, chemical, and microbiological properties of formulated carrot juice. Food Science and Technology International. 2009;15(3):275–82.

- McAuley CM, Singh TK, Haro-Maza JF, Williams R, Buckow R. Microbiological and physicochemical stability of raw, pasteurised or pulsed electric field-treated milk. Innovative Food Science and Emerging Technologies. 2016 Dec 1;38:365–73.

- Thamsuaidee A, Schaefer E, Schneider D, Siemer C, Valdramidis P. Disentangling the effects of electroporation and heat during pulsed electric field ( PEF ) processing of oat-based milk alternative : A case study on Lactiplantibacillus plantarum inactivation. Innovative Food Science and Emerging Technologies [Internet]. 2024;94(January):103691. Available from: https://doi.org/10.1016/j.ifset.2024.103691

- Manzoor MF, Zeng XA, Ahmad N, Ahmed Z, Rehman A, Aadil RM, et al. Effect of pulsed electric field and thermal treatments on the bioactive compounds, enzymes, microbial, and physical stability of almond milk during storage. J Food Process Preserv. 2020 Jul 1;44(7).

- Horlacher N, Oey I, Ying S. Effect of pulsed electric field processing on microbial and enzyme inactivation in blended plant-based milk alternatives : A case study on a microbial challenge test for a non-presterilized oat-based beverage enriched with pea protein. Innovative Food Science and Emerging Technologies [Internet]. 2024;94(May):103699. Available from: https://doi.org/10.1016/j.ifset.2024.103699

- Li YQ, Tian WL, Mo HZ, Zhang YL, Zhao XZ. Effects of Pulsed Electric Field Processing on Quality Characteristics and Microbial Inactivation of Soymilk. Food Bioproc Tech. 2013 Aug;6(8):1907–16.

- Pataro G, Ferrari G. Electrochemical Reactions in Pulsed Electric Fields Treatment. In: Raso J, Heinz V, Alvarez I, Toepfl S, editors. Pulsed Electric Fields Technology for the Food Industry: Fundamentals and Applications. 2nd ed. Cham, Switzerland: Springer Nature Switzerland AG; 2022. p. 143–66.

Further Reading

Exploring Pulsed Electric Field (PEF) Microbial Inactivation for Food Processing

Non-thermal plasma (NTP) for the improvement of food safety and quality

The Impact of Strain Variability on the Inactivation Efficacy of Ultrasound Technology

Understanding Consumer Perception in Food Product Development: Key to Market Success