Fungal Infections, Toxin Production, and Nutritional Quality in Food and Feed

Exploring Fungal Infections, Toxin Production, and Nutritional Quality in Agriculture Products (Food and Feed): Understanding Contamination Pathways and Implementing Effective Control Measures

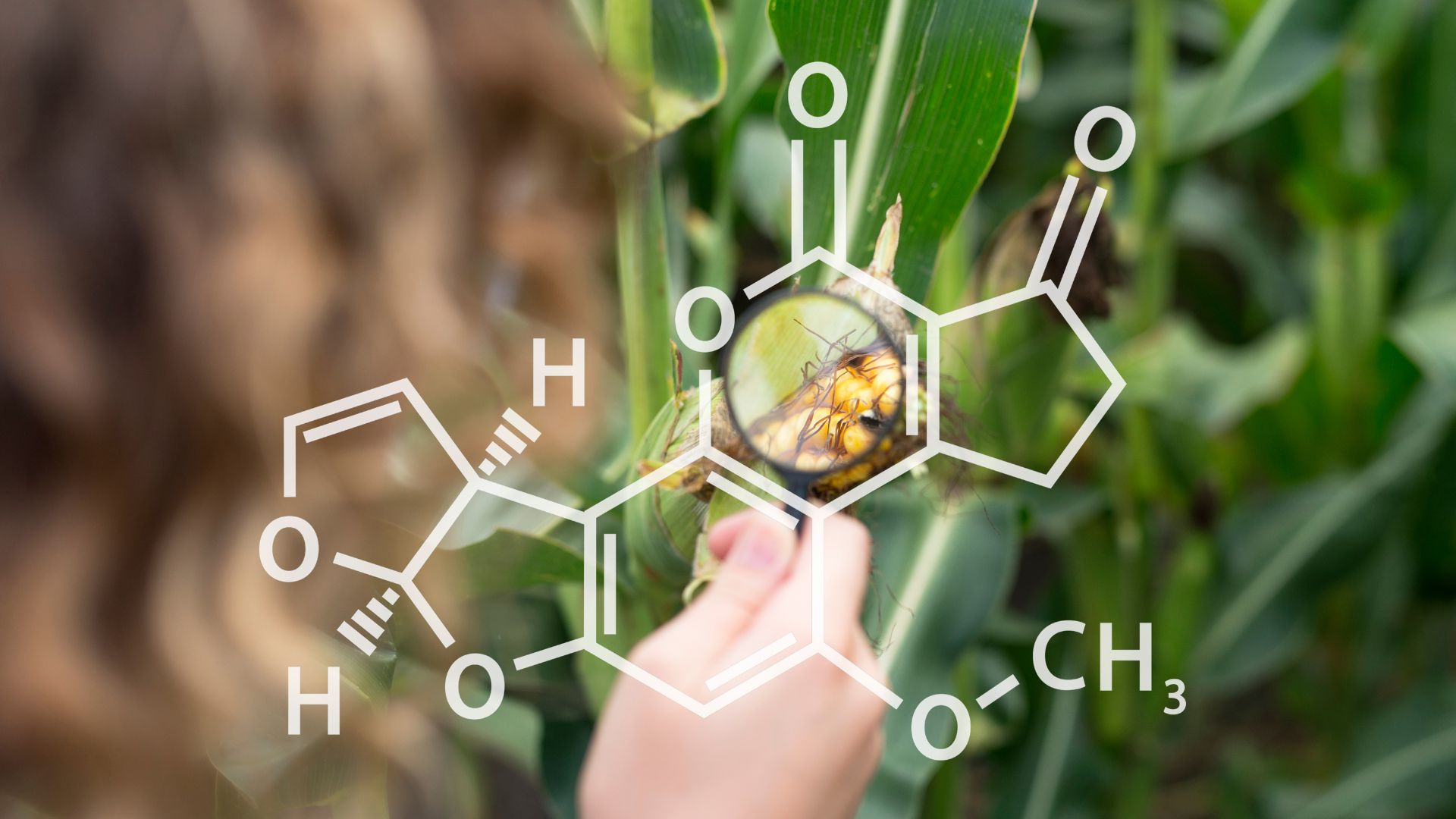

Aflatoxins present a pressing global concern due to their profound impact on public health and economies worldwide. Originating from fungal species within the Aspergillus genus, these toxic, mutagenic, and carcinogenic metabolites consistently contaminate various food and agricultural products. Aflatoxin contamination is significantly influenced by climate and diet, with warmer climates and aflatoxin-susceptible staple foods contributing substantially to the global burden. Regulatory measures, prevention strategies, decontamination, and detoxification efforts have been employed to mitigate human exposure to aflatoxins. Detection methods leveraging aflatoxins’ chemical and structural properties play a crucial role in monitoring and quantifying their presence in foods. Beyond public health, aflatoxin contamination carries significant trade and economic implications globally. For instance, maize farmers in the United States face annual losses of $160 million due to aflatoxin-related issues, while developing countries, particularly in sub-Saharan Africa, incur losses amounting to $450 million, representing 38% of global agricultural losses attributed to aflatoxin. Effective implementation of Good Agricultural Practices (GAPs), Good Manufacturing Practices (GMPs), Hazard Analysis Critical Control Points (HACCP), proper storage, informed stakeholders, and the ability to predict on-field and in-store contamination are crucial preventive measures against human exposure to aflatoxins. Long-term strategies should focus on minimizing on-field contamination through bio-control measures or cultivating resistant crop varieties. When rigorously enforced, regulations serve as the last line of defense before food reaches consumers. While many countries worldwide have enacted aflatoxin-related regulations, a significant portion of African countries lacks such regulations. Precise, accurate, affordable, and simple aflatoxin detection methods are essential for enforcing regulations and assessing the efficacy of aflatoxin control measures. While current chromatographic, immunochemical, and spectroscopic methods are effective, ongoing efforts to develop new or improved methods aim to enhance speed, detection, and accuracy, ultimately ensuring the safety of food and agricultural products.

Aspergillus flavus Contamination

Aspergillus flavus, characterized as a saprotrophic and pathogenic fungus, exhibits a widespread global distribution. Its notable affinity lies in the colonization of cereal grains, legumes, and tree nuts. The onset of postharvest rot typically manifests during harvest, storage, and/or transit phases. The specific epithet ‘flavus’ originates from the Latin word meaning yellow, aptly describing the frequently observed coloration of its spores. Infections by A. flavus can occur both in the field preharvest and during postharvest stages, with preharvest infections often remaining asymptomatic until the postharvest storage or transport period. Beyond its ability to cause preharvest and postharvest infections, numerous strains of A. flavus produce substantial quantities of mycotoxins. These toxic compounds, when ingested, pose a threat to mammals. Notably, A. flavus also serves as an opportunistic pathogen for humans and animals, contributing to the development of aspergillosis, particularly in immunocompromised individuals.

Aflatoxin

Aflatoxins are various poisonous carcinogens and mutagens that are naturally produced by certain molds, particularly Aspergillus species (Aspergillus flavus and Aspergillus parasiticus). Aflatoxins are synthesized by many fungi spp. including Aspergillus, Penicillium, Fusarium, and Alternaria, but Aspergillus flavus and Aspergillus parasiticus are known to produce the most toxigenic strains of aflatoxins. There are mainly six different types of aflatoxins-Aflatoxins-B1(AFB1), Aflatoxins-B2(AFB2), Aflatoxin G1(AFG1), Aflatoxins G2 (AFG2), Aflatoxin M1 (AFM1), and Aflatoxin M2 (AFM2). Out of these, B1, B2, G1, and G2 are found in food crops or their products, while M1 (Metabolite of B1) and M2 are found in the animals’ by-products such as dairy products. The fungi grow in soil, decaying vegetation and various staple foodstuffs and commodities such as hay, sweetcorn, wheat, millet, sorghum, cassava, rice, chill, peppers, cottonseed, peanuts, tree nuts, sesame seeds, sunflower seeds, maize, rice, figs and other dried foods, crude vegetable oils and cocoa beans, as a result of fungal contamination before and after harvest and various spices. In short, the relevant fungi grow on almost any crop or food. When such contaminated food is processed or consumed, the aflatoxins enter the general food supply. They have been found in both pet and human foods, as well as in feedstocks for agricultural animals. Aflatoxin is the main mycotoxin that harms animal and human health due to its carcinogenic nature. AFB1 constitutes the most harmful type of aflatoxins and is a potent hepato-carcinogenic; several types of aflatoxins are produced naturally. Aflatoxin B1 is the most common in food and among the most potent genotoxic and carcinogenic. Aflatoxin M1 is a major metabolite of aflatoxin B1 in humans and animals, which may be present in milk from animals fed with aflatoxin B1 contaminated feed.

Health hazards of aflatoxins

Aflatoxins are fungal toxins known for their acute life-threatening toxicity, carcinogenic properties, and other potential chronic adverse effects. Aflatoxin B1 stands out as the most detrimental aflatoxin for both humans and animals, given its carcinogenic nature and its link to hepatocellular carcinoma, ultimately resulting in liver cancer. Children, in particular, are more vulnerable to the toxic effects of aflatoxin, heightening the risk of early infections due to compromised immunization. Beyond its carcinogenic properties, aflatoxin also exerts adverse effects on various vital organs such as the kidneys, heart, liver, testes, and brain.

The issue of dietary exposure to aflatoxins is a significant public health concern, particularly in subsistence farming communities in sub-Saharan Africa and South Asia. In these regions, dietary staple food crops like groundnuts and maize are often highly contaminated with aflatoxin due to hot and humid climates, poor storage practices, low awareness of the risks, and a lack of enforcement of regulatory limits. Biomarkers have been developed and utilized in numerous epidemiological studies to assess aflatoxin exposure and its associated health effects in these high-risk population groups. Recent evidence suggests that aflatoxin may be an underlying factor contributing to stunted child growth and may lower cell-mediated immunity, potentially increasing susceptibility to diseases. However, establishing a causal relationship between aflatoxin exposure and these adverse health outcomes remains a challenge, and the biological mechanisms for these effects have not been fully elucidated, warranting further research. Additionally, there is limited information on the health effects of co-exposure to aflatoxin with other mycotoxins. Recent advancements in biomarkers offer opportunities for crucial future research in this field. Aflatoxin contamination in crops is a global threat that not only compromises the safety of food and feed but also impacts the agricultural economy and crop-dependent small-scale industries.

Conditions that allow the aflatoxin contamination

Aspergillus, is a fungus found especially in areas with hot and humid climates. Climate change is expected to have an impact on the presence of aflatoxins in food in Europe. As aflatoxins are known to be genotoxic and carcinogenic, exposure through food should be kept as low as possible. Mycotoxin production depends on the food source, enzymes, and various environmental factors. However, the conditions that are favorable for aflatoxigenic fungi are not always conducive to the production of aflatoxins. There are several factors which are as;

Physical factors

Various physical factors play a crucial role in aflatoxin contamination, with pH, light, moisture, temperature, water, relative humidity, and atmospheric gases being significant contributors. Aflatoxin-producing molds or fungi exhibit adaptability to a wide pH range (1.7–9.3), with the optimum range being 3–7. Lower pH (3 > pH > 1) restricts fungal growth, while slightly higher pH (6 > pH > 3) promotes both fungal and aflatoxin production. An initial pH of 5 promotes Aflatoxin B (AFB) production, whereas a higher pH of 7 promotes Aflatoxin G (AFG) production. The composition of the growth medium also influences pH.

Light conditions significantly impact fungal growth and aflatoxin production. Darkness enhances aflatoxin production, while exposure to sunlight inhibits it. Moisture content is a critical factor, favoring aflatoxin contamination under high moisture conditions due to the conducive environment for fungal growth. Relative humidity at 85% is optimal for aflatoxin production, and higher levels, such as 95%, further increase aflatoxin production. However, water levels do not have a reported effect on aflatoxin contamination. Aspergillus flavus, the primary aflatoxin producer, exhibits robust survival capabilities over a broad temperature range from 12 °C to 48 °C, with the optimal temperature for growth falling between 28 °C and 37 °C. Aflatoxins can be produced across a wide temperature range, but the optimal temperature for aflatoxin production is 25-35 °C. Higher temperatures tend to favor AFB production over AFG, while at lower temperatures, both AFB and AFG production is equal. The availability of oxygen (O2) and carbon dioxide (CO2) also influences aflatoxin production. Higher levels of CO2 and lower levels of O2 inhibit aflatoxin production and fungal growth.

Nutritional factors

Aflatoxin production is significantly influenced by the substrate and various nutritional factors, including carbon, amino acids, nitrogen, lipids, and trace elements. Substrates rich in carbohydrates support higher production compared to oil, as carbohydrates readily provide the carbon essential for robust fungal growth. Glucose, ribose, sucrose, xylose, and glycerol are excellent carbohydrate substrates, while peptone, lactose, and sorbose fail to stimulate aflatoxin production. Nitrogen, present in the form of nitrite and nitrate, enhances aflatoxin production by A. flavus through various mechanisms.

Lipids play a crucial role in aflatoxin production, with biosynthesis initiated by lipophilic epoxy fatty acids. Fungal growth and aflatoxin production are induced by ergosterol oxidation. Consequently, lipids serve as both a substrate to obtain an acyl-CoA starter and a signaling molecule. Aflatoxin production and accumulation are higher in full-fat substrates compared to low-fat substrates. Additionally, vitamins, amino acids, and metal ions collectively promote aflatoxin production. Amino acids such as glycine, glutamate, alanine, and bivalent metals like zinc and magnesium contribute to promoting aflatoxin production.

Biological factors

Biological factors encompass fungal species, weeds, and insect-induced injuries. Weeds primarily function as competitors, inducing plant stress that correlates with aflatoxin production. The quantity of aflatoxin generated is predominantly influenced by the types of fungi present. Insect-induced wounds in plants cause stress and create a conducive environment for aflatoxigenic fungi contamination. The variation in aflatoxin production is also contingent on the fungal strains involved. A. flavus tends to produce fewer aflatoxins compared to A. parasiticus. Notably, A. flavus emerges as the principal species responsible for aflatoxin production and crop contamination. Its prevalence in soil, coupled with its saprobe characteristics, enables it to thrive on various organic nutrient substrates, including compost piles, plant debris, cotton, deceased insects, stored grains, field crops, animal remains, and animal fodder. Pre-harvest contaminations of field crops are frequent due to the natural presence of A. flavus in soil, while post-harvest contamination occurs during storage, where A. flavus can spoil stored food grains. A. flavus lacks host specificity, contaminating both monocot and dicot seeds.

Contamination

Aspergillus flavus extensively contaminates a diverse array of food commodities, encompassing cereals (such as maize, sorghum, pearl millet, rice, and wheat), oilseeds (peanut, soybean, sunflower, and cotton), spices (including chilies, black pepper, turmeric, coriander, and ginger), nuts (almond, Brazil nut, pistachio, walnut, and coconut), yams, and various milk products. Displaying a green appearance, the A. flavus fungus demonstrates the ability to proliferate even under challenging conditions. Injuries inflicted by insects and nematodes create openings for these fungi to infiltrate. Mycotoxins, including aflatoxins, can emerge during the growth stages of specific crops. The occurrence of particular mycotoxins is influenced by a combination of climate, sources of fungal inoculum (or suitability of the fungal substrate), potential insect vectors, and the plant’s response (or its susceptibility to fungal infestation). Insect-induced damage exposes vulnerable tissues to colonization by toxigenic fungi, leading to subsequent aflatoxin production. The intrusion of fungi into crops not only compromises the self-defence mechanisms of crop plants but also results in the contamination of crop seeds, leading to aflatoxin production. Fungal infections adversely impact the growth and yield of crops, ultimately causing a loss of market value.

Methods of Aflatoxin Detection

The most widely employed method is the Enzyme-Linked Immunosorbent Assay (ELISA), followed by various chromatographic techniques such as High-Performance Liquid Chromatography (HPLC), Liquid Chromatography-Mass Spectroscopy (LCMS), and Thin Layer Chromatography (TLC). Methods that yield rapid results are particularly valuable for handling large sample sizes. Polymerase Chain Reaction (PCR), Fluorescence/Near-Infrared Spectroscopy (FS/NIRS), and Hyper Spectral Imaging (HSI) fall into this category. The PCR technique is primarily utilized for molecular-level detection of Aflatoxins-producing fungi, specifically A. flavus. Genes identified during the molecular screening of A. flavus, responsible for Aflatoxin biosynthesis, serve as target genes for Aflatoxin detection using multiplex PCR.

The visible/Near-Infrared technique (VNIR) is also employed for toxin contamination detection, although recent studies have focused on enhancing the image quality by combining HSI with chemometric data analysis. This combination has resulted in improved identification of AFB1 on maize kernel surfaces. Advancements in analytical techniques have facilitated the simultaneous detection of aflatoxins with other toxic compounds. Time-Resolved Fluorescence Immuno-Chromatographic Assay (TRFICA) and anti-idiotypic nanobody-Phage Display-mediated Immune-Polymerase Chain Reaction (PD-IPCR) are employed for the concurrent detection of aflatoxins and zearalenone, providing detection limits of 0.05 ng/mL and 0.03 ng/mL, respectively, for aflatoxins. Another recent method detects aflatoxins and fumonisins (a group of mycotoxins derived from Fusarium spp.) through Color-encoded Lateral Flow Immuno-Assay (CLFIA). Additionally, the use of biosensors for AFB1 detection in crop products, as opposed to chromatographic or spectrophotometric methods, has gained popularity. Biosensors offer easy and rapid detection, reduced expenses, minimal sample pretreatment, portability, and on-the-spot identification of aflatoxins using an electrochemical enzyme-linked oligonucleotide array.

Measures to Control Aflatoxin Contamination

The extent and intensity of contamination are contingent upon factors such as temperature, humidity, and conditions prevalent in both soil and storage environments. The most efficacious strategy for curtailing mycotoxin contamination lies in prevention, focusing on the exclusion or reduction of toxigenic mold proliferation and toxin production in vulnerable food crops. Practical implementation involves minimizing fungal infections during crop growth through prompt drying and proper storage of harvested crops, employing effective anti-mold preservatives, and adhering to correct postharvest processing, transport, and distribution practices.

Aflatoxin contamination in crops poses a severe threat to production, the food market, health, and economics. Diverse approaches, encompassing physical, chemical, and biological methods, have been devised to mitigate aflatoxin contamination in crops. Effectively preventing mycotoxin contamination during storage predominantly hinges on meticulous moisture control of the crop. This involves eliminating insect activity, which can create favorable microclimates for toxigenic fungal growth, preventing moisture migration, condensation, or water leaks, and curbing rodent activity to prevent increased moisture levels from urination. In essence, conditions that impede fungal growth will invariably curtail or eliminate mycotoxin production.

Harvesting during dry weather generally results in less alarming mycotoxin contamination. Conversely, challenges arise when harvesting takes place in highly humid weather. In numerous developing countries, the amalgamation of insufficient drying equipment and humid atmospheric conditions leads to unacceptable levels of aflatoxin in harvested groundnuts, tree nuts, and other food commodities.

Measures to prevent aflatoxin contamination.

Physical methods

Various physical methods, including steam under pressure, dry roasting, and other cooking techniques, have proven effective in managing or diminishing aflatoxin contamination in numerous crops. A significant reduction in aflatoxin levels, ranging from 40% to 73%, has been documented by subjecting seed samples to heat at 180 °C. Roasting groundnut and corn seeds with 30% moisture at 100 °C for 2 h resulted in an impressive 85% reduction in aflatoxin content. Moreover, roasting at 150 °C for 15 min led to a notable decrease of 70% and 79% in the concentrations of AFB1 and AFG1, respectively. The application of various radiations, such as UV and Infrared radiation, also demonstrated an effective reduction in aflatoxin concentration when applied to seeds. Sunlight emerges as a crucial factor in the detoxification of AFB1 in multiple crops. Exposure to sunlight for a duration of 10–12 h led to a reduction in AFB1 content in artificially infected maize (80%) and groundnut (17%). Additionally, gamma radiation exposure has been identified as another method to diminish aflatoxin levels.

Chemical methods

Numerous chemicals, including acids, alkalis, oxidizing agents, aldehydes, and various gases, have demonstrated efficacy in suppressing aflatoxigenic fungal growth and aflatoxin production when applied in appropriate concentrations. Among gases, ozone stands out as the most effective in promoting aflatoxin degradation in legumes and cereals through an electrophilic attack on carbon bonds within the furan ring. However, the high cost associated with ozone treatment limits its practicality for post-harvest crop treatment. Certain chemicals, such as sodium bisulfite, calcium hydroxide, formaldehyde, sodium hypochlorite, sodium borate, and sorbents, have shown significant potential in reducing aflatoxin levels across various food commodities.

Moreover, some food additives, when combined with specific physical factors like temperature and moisture, inhibit fungal growth and aflatoxin production. Notably, certain food preservatives like propionic acid, crystal violet, p-amino benzoic acid, benzoic acid, boric acid, and sodium acetate have demonstrated inhibitory effects on A. flavus growth and aflatoxin production. Even under conditions favoring A. flavus growth, several propionic acid salts, such as calcium and sodium propionates, have exhibited the ability to diminish aflatoxin formation in maize. Azole fungicides, particularly prochloraz, have been employed as effective tools to control fungal growth and aflatoxin production, surpassing the efficacy of tebuconazole.

Biological methods

Biological agents, including bacteria, yeasts, molds, and algae, exhibit diverse capabilities for aflatoxin degradation in the environmental context. The detoxification of aflatoxins through biological agents involves two processes: absorption and enzymatic decadence. Microorganisms can directly absorb aflatoxins by binding to their cell wall constituents through effective internalization or aggregation. Even dead microorganisms possess the ability to absorb aflatoxins, offering potential applications in the development of probiotic-based bio-filters for fluid decontamination.

Additionally, aflatoxin degradation can occur through intra or extracellular enzymes, with the resulting end products primarily being water and CO2. In a study assessing the efficacy of different microbial strains, Flavobacterium aurantiacum B-184 emerged as the most effective for aflatoxin degradation. Various bacterial strains, including Bacillus velezensis DY3108, demonstrated notable effectiveness against AFB1 degradation, with the cell-free supernatant of the latter exhibiting a robust AFB1 degradation activity of 91.5%. Furthermore, the inoculation of antagonistic strains of Pseudomonas, Trichoderma, Ralstonia, Lactobacilli, Burkholderia, and Bacillus spp. led to a noteworthy reduction in A. flavus growth in pre-harvest crops. Surprisingly, the use of non-toxigenic strains of A. flavus and other molds emerged as an effective control agent, inhibiting aflatoxin contamination.

Further Reading

Aflatoxin Contamination in Corn

Aflatoxin Contamination of Pistachio nuts

Contaminant Detection: Tools for Ensuring Food Safety

References

Aflatoxins in food | EFSA (europa.eu)

Aiko, V., Edamana, P., & Mehta, A. (2016). Decomposition and detoxification of aflatoxin B1 by lactic acid. Journal of the Science of Food and Agriculture, 96(6), 1959-1966.

Akocak, P. B., Churey, J. J., & Worobo, R. W. (2015). Antagonistic effect of chitinolytic Pseudomonas and Bacillus on growth of fungal hyphae and spores of aflatoxigenic Aspergillus flavus. Food Bioscience, 10, 48-58.

Aliabadi, M. A., Alikhani, F. E., Mohammadi, M., & Darsanaki, R. K. (2013). Biological control of aflatoxins. European Journal of Experimental Biology, 3(2), 162-166.

Amaike, S., & Keller, N. P. (2011). Aspergillus flavus. Annual review of phytopathology, 49, 107-133.

Aquino, S., & Corrêa, B. (2011). Aflatoxins in pet foods: a risk to special consumers. Aflatoxins-Detection, Measurement and Control.

AS, M., Manjunath, K., & Mohana, D. C. (2018). Assessment of contamination levels and characterization of aflatoxin B1 producing Aspergillus flavus strain from food and feed samples from local markets of South India. Int. J. of Life Sciences, 6(1), 326-334.

Bedi, P. S., & Agarwal, R. K. (2014). Detoxification of aflatoxin B1 by physical and chemical methods. World Journal of Pharmacy and Pharmaceutical Sciences, 3(12), 995-1002.

Bolu, S. A., Elelu, N., Ahmed, R. N., Solaojo, F. E., Daramola, K. F., Omotosho, V. S., & Afeni, M. (2014). Effect of vitamins, amino acids, and Phyto-active biomolecules on Aspergillus flavus in poultry production. Pharmacology and Therapeutics, 21-58.

Brožková, I., Šmahová, P., Vytřasová, J., Moťková, P., Pejchalová, M., & Šilha, D. (2015). Influence of chosen microbes and some chemical substances on the production of aflatoxins. Potravinarstvo, 9(1).

Carvajal, M., & Castillo, P. (2009). Effects of aflatoxins contaminating food on human health. Tropical Biology and Conservation Management, 7, 60-84.

Dalié, D. K. D., Deschamps, A. M., & Richard-Forget, F. (2010). Lactic acid bacteria–Potential for control of mould growth and mycotoxins: A review. Food control, 21(4), 370-380.

Darsanaki, R., & Miri, M. (2013). Aflatoxin M1 contamination in dairy products. Journal of Science and today’s world, 2, 500-514.

Di Nardo, F., Alladio, E., Baggiani, C., Cavalera, S., Giovannoli, C., Spano, G., & Anfossi, L. (2019). Colour-encoded lateral flow immunoassay for the simultaneous detection of aflatoxin B1 and type-B fumonisins in a single Test line. Talanta, 192, 288-294.

Ding, D., Pan, Z., Cuiuri, D., & Li, H. (2015). Wire-feed additive manufacturing of metal components: technologies, developments and future interests. The International Journal of Advanced Manufacturing Technology, 81, 465-481.

Elhassaneen, Y. A., Gorge, S., Elkhamisy, A. E., & Negm, S. H. (2016). Removal techniques of aflatoxin from contaminated commodities: A review study. Journal of Home, 5, 6.

Fratamico, P. M., Bhunia, A. K., & Smith, J. L. (2005). Foodborne pathogens: microbiology and molecular biology. CRC Press LLC.

Fuquay, J. W., Fox, P. F., & McSweeney, P. L. (2011). Encyclopedia of dairy sciences. (No Title)

Gbashi, S., Madala, N. E., De Saeger, S., De Boevre, M., Adekoya, I., Adebo, O. A., & Njobeh, P. B. (2018). The socio-economic impact of mycotoxin contamination in Africa. Fungi and mycotoxins-their occurrence, impact on health and the economy as well as pre-and postharvest management strategies (ed. Njobeh, PB), 1-20.

Gong, Y. Y., Watson, S., & Routledge, M. N. (2016). Aflatoxin exposure and associated human health effects, a review of epidemiological studies. Food safety, 4(1), 14-27.

Guo, Y., Qin, X., Tang, Y., Ma, Q., Zhang, J., & Zhao, L. (2020). CotA laccase, a novel aflatoxin oxidase from Bacillus licheniformis, transforms aflatoxin B1 to aflatoxin Q1 and epi-aflatoxin Q1. Food chemistry, 325, 126877.

Hassane, A. M. A., El-Shanawany, A. A., Abo-Dahab, N. F., Abdel-Hadi, A. M., Abdul-Raouf, U. M., & Mwanza, M. (2017). Influence of different moisture contents and temperature on growth and production of aflatoxin B1 by a toxigenic Aspergillus flavus isolate in wheat flour. J. Ecol. Heal. Environ, 5, 77-83.

Hawkins, J. D., Kosterman, R., Catalano, R. F., Hill, K. G., & Abbott, R. D. (2005). Promoting positive adult functioning through social development intervention in childhood: Long-term effects from the Seattle Social Development Project. Archives of pediatrics & adolescent medicine, 159(1), 25-31.

Jalili, M. (2016). A review on aflatoxins reduction in food. Iranian Journal of Health, Safety and Environment, 3(1), 445-459.

Jallow, A., Xie, H., Tang, X., Qi, Z., & Li, P. (2021). Worldwide aflatoxin contamination of agricultural products and foods: From occurrence to control. Comprehensive reviews in food science and food safety, 20(3), 2332-2381.

Jard, G., Liboz, T., Mathieu, F., Guyonvarc’h, A., & Lebrihi, A. (2011). Review of mycotoxin reduction in food and feed: from prevention in the field to detoxification by adsorption or transformation. Food Additives & Contaminants: Part A, 28(11), 1590-1609.

Jeyaramraja, P. R., Meenakshi, S. N., & Woldesenbet, F. (2018). Relationship between drought and preharvest aflatoxin contamination in groundnut (Arachis hypogaea L.). World Mycotoxin Journal, 11(2), 187-199.

Kakde, U. K., & Kakde, H. U. (2012). Incidence of post-harvest disease and airborne fungal spores in a vegetable market. Acta Botanica Croatica, 71(1), 147-157.

Karlovsky, P., Suman, M., Berthiller, F., De Meester, J., Eisenbrand, G., Perrin, I., … & Dussort, P. (2016). Impact of food processing and detoxification treatments on mycotoxin contamination. Mycotoxin research, 32, 179-205.

Kimuli, D., Wang, W., Jiang, H., Zhao, X., & Chu, X. (2018). Application of SWIR hyperspectral imaging and chemometrics for identification of aflatoxin B1 contaminated maize kernels. Infrared Physics & Technology, 89, 351-362.

Kinyungu, S., Isakeit, T., Ojiambo, P. S., & Woloshuk, C. P. (2019). Spread of Aspergillus flavus and aflatoxin accumulation in postharvested maize treated with biocontrol products. Journal of Stored Products Research, 84, 101519.

Klich, M. A. (2007). Aspergillus flavus: the major producer of aflatoxin. Molecular plant pathology, 8(6), 713-722.

Kumar, A., Pathak, H., Bhadauria, S., & Sudan, J. (2021). Aflatoxin contamination in food crops: causes, detection, and management: a review. Food Production, Processing and Nutrition, 3, 1-9.

Leong, Y. H., Rosma, A., Latiff, A. A., & Ahmad, N. I. (2011). Exposure assessment and risk characterization of aflatoxin B 1 in Malaysia. Mycotoxin Research, 27, 207-214.

Liu, X., Guan, X., Xing, F., Lv, C., Dai, X., & Liu, Y. (2017). Effect of water activity and temperature on the growth of Aspergillus flavus, the expression of aflatoxin biosynthetic genes and aflatoxin production in shelled peanuts. Food Control, 82, 325-332.

Ma, X., Wang, W., Chen, X., Xia, Y., Wu, S., Duan, N., & Wang, Z. (2014). Selection, identification, and application of Aflatoxin B1 aptamer. European Food Research and Technology, 238, 919-925.

Machida, M., & Gomi, K. (2010). Aspergillus: molecular biology and genomics. (No Title)

Mahbobinejhad, Z., Aminian, H., Ebrahimi, L., & Vahdati, K. (2019). Reduction of aflatoxin production by exposing Aspergillus flavus to CO2. Journal of Crop Protection, 8(4), 441-448.

Mannaa, M., & Kim, K. D. (2017). Influence of temperature and water activity on deleterious fungi and mycotoxin production during grain storage. Mycobiology, 45(4), 240.

Mateo, E. M., Gómez, J. V., Gimeno-Adelantado, J. V., Romera, D., Mateo-Castro, R., & Jiménez, M. (2017). Assessment of azole fungicides as a tool to control growth of Aspergillus flavus and aflatoxin B1 and B2 production in maize. Food Additives & Contaminants: Part A, 34(6), 1039-1051.

Matumba, L., Sulyok, M., Njoroge, S. M., Njumbe Ediage, E., Van Poucke, C., De Saeger, S., & Krska, R. (2015). Uncommon occurrence ratios of aflatoxin B 1, B 2, G 1, and G 2 in maize and groundnuts from Malawi. Mycotoxin research, 31, 57-62.

Matumba, L., Sulyok, M., Njoroge, S. M., Njumbe Ediage, E., Van Poucke, C., De Saeger, S., & Krska, R. (2015). Uncommon occurrence ratios of aflatoxin B 1, B 2, G 1, and G 2 in maize and groundnuts from Malawi. Mycotoxin research, 31, 57-62.

Méndez-Albores, A., Veles-Medina, J., Urbina-Álvarez, E., Martínez-Bustos, F., & Moreno-Martínez, E. (2009). Effect of citric acid on aflatoxin degradation and on functional and textural properties of extruded sorghum. Animal feed science and technology, 150(3-4), 316-329.

Motawe, H. F. A., Salam, A. A., & El Meleigy, K. M. (2014). Reducing the toxicity of aflatoxin in broiler chickens’ diet by using probiotic and yeast. International Journal of Poultry Science, 13(7), 397.

Mwakinyali, S. E., Ding, X., Ming, Z., Tong, W., Zhang, Q., & Li, P. (2019). Recent development of aflatoxin contamination biocontrol in agricultural products. Biological Control, 128, 31-39.

Peng, Z., Chen, L., Zhu, Y., Huang, Y., Hu, X., Wu, Q., … & Yang, W. (2018). Current major degradation methods for aflatoxins: A review. Trends in Food Science & Technology, 80, 155-166.

Quadri, S. H., Ms, N., Kc, C., Shantaram, U., & Hs, E. (2012). An overview on chemistry, toxicity, analysis and control of aflatoxins. International Journal of Chemical and Life Sciences, 2, 1071-1078.

Qureshi, H., Hamid, S. S., Ali, S. S., Anwar, J., Siddiqui, A. A., & Khan, N. A. (2015). Cytotoxic effects of aflatoxin B1 on human brain microvascular endothelial cells of the blood-brain barrier. Medical mycology, 53(4), 409-416.

Rajarajan, P. N., Rajasekaran, K. M., & Devi, N. A. (2013). Aflatoxin contamination in agricultural commodities. Indian Journal of Pharmaceutical and Biological Research, 1(04), 148-151.

Ramírez-Camejo, L. A., Zuluaga-Montero, A., Lázaro-Escudero, M., Hernández-Kendall, V., & Bayman, P. (2012). Phylogeography of the cosmopolitan fungus Aspergillus flavus: is everything everywhere?. Fungal Biology, 116(3), 452-463.

Rotariu, L., Lagarde, F., Jaffrezic-Renault, N., & Bala, C. (2016). Electrochemical biosensors for fast detection of food contaminants–trends and perspective. TrAC Trends in Analytical Chemistry, 79, 80-87.

Rushing, B. R., & Selim, M. I. (2019). Aflatoxin B1: A review on metabolism, toxicity, occurrence in food, occupational exposure, and detoxification methods. Food and chemical toxicology, 124, 81-100.

Rushing, B. R., & Selim, M. I. (2019). Aflatoxin B1: A review on metabolism, toxicity, occurrence in food, occupational exposure, and detoxification methods. Food and chemical toxicology, 124, 81-100.

Selvolini, G., Lettieri, M., Tassoni, L., Gastaldello, S., Grillo, M., Maran, C., & Marrazza, G. (2019). Electrochemical enzyme-linked oligonucleotide array for aflatoxin B1 detection. Talanta, 203, 49-57.

Shu, X., Wang, Y., Zhou, Q., Li, M., Hu, H., Ma, Y., … & Wu, L. (2018). Biological degradation of aflatoxin B1 by cell-free extracts of Bacillus velezensis DY3108 with broad pH stability and excellent thermostability. Toxins, 10(8), 330.

Siciliano, I., Dal Bello, B., Zeppa, G., Spadaro, D., & Gullino, M. L. (2017). Static hot air and infrared rays roasting are efficient methods for aflatoxin decontamination on hazelnuts. Toxins, 9(2), 72.

St. Leger, R. J., Screen, S. E., & Shams-Pirzadeh, B. (2000). Lack of host specialization in Aspergillus flavus. Applied and Environmental Microbiology, 66(1), 320-324.

Surekha, M., Reddy, V. K., & Reddy, S. M. (2015). Ecofriendly management of mycotoxigenic fungi and mycotoxin contamination. In Sustainable crop disease management using natural products (pp. 265-292). Wallingford UK: CABI.

Tao, F., Yao, H., Hruska, Z., Burger, L. W., Rajasekaran, K., & Bhatnagar, D. (2018). Recent development of optical methods in rapid and non-destructive detection of aflatoxin and fungal contamination in agricultural products. TrAC Trends in Analytical Chemistry, 100, 65-81.

Temba, M. C., Njobeh, P. B., & Kayitesi, E. (2017). Storage stability of maize-groundnut composite flours and an assessment of aflatoxin B1 and ochratoxin A contamination in flours and porridges. Food Control, 71, 178-186.

Tirmenstein, M., Horvath, J., Graziano, M., Mangipudy, R., Dorr, T., Colman, K., … & Janovitz, E. (2015). Utilization of the Zucker diabetic fatty (ZDF) rat model for investigating hypoglycemia-related toxicities. Toxicologic Pathology, 43(6), 825-837.

Udomkun, P., Wiredu, A. N., Nagle, M., Müller, J., Vanlauwe, B., & Bandyopadhyay, R. (2017). Innovative technologies to manage aflatoxins in foods and feeds and the profitability of application–A review. Food control, 76, 127-138.

Udomkun, P., Wiredu, A. N., Nagle, M., Müller, J., Vanlauwe, B., & Bandyopadhyay, R. (2017). Innovative technologies to manage aflatoxins in foods and feeds and the profitability of application–A review. Food control, 76, 127-138.

Verma, R. J. (2004). Aflatoxin cause DNA damage. International Journal of Human Genetics, 4(4), 231-236.

Wacoo, A. P., Wendiro, D., Vuzi, P. C., & Hawumba, J. F. (2014). Methods for detection of aflatoxins in agricultural food crops.

Wang, B., Han, X., Bai, Y., Lin, Z., Qiu, M., Nie, X., … & Wang, S. (2017). Effects of nitrogen metabolism on growth and aflatoxin biosynthesis in Aspergillus flavus. Journal of hazardous materials, 324, 691-700.

Wei, T., Ren, P., Huang, L., Ouyang, Z., Wang, Z., Kong, X., … & He, Q. (2019). Simultaneous detection of aflatoxin B1, ochratoxin A, zearalenone and deoxynivalenol in corn and wheat using surface plasmon resonance. Food chemistry, 300, 125176.

Wu, L. X., Ding, X. X., Li, P. W., Du, X. H., Zhou, H. Y., Bai, Y. Z., & Zhang, L. X. (2016). Aflatoxin contamination of peanuts at harvest in China from 2010 to 2013 and its relationship with climatic conditions. Food Control, 60, 117-123.

Yang, B., Zhang, C., Zhang, X., Wang, G., Li, L., Geng, H., … & Nie, C. (2020). Survey of aflatoxin B1 and heavy metal contamination in peanut and peanut soil in China during 2017–2018. Food Control, 118, 107372.

Yoshinari, T., Noda, Y., Yoda, K., Sezaki, H., Nagasawa, H., & Sakuda, S. (2010). Inhibitory activity of blasticidin A, a strong aflatoxin production inhibitor, on protein synthesis of yeast: Selective inhibition of aflatoxin production by protein synthesis inhibitors. The Journal of Antibiotics, 63(6), 309-314.

Zhao, Y., Zhu, A., Tang, J., Tang, C., & Chen, J. (2017). Identification and measurement of staphylococcal enterotoxin M from Staphylococcus aureus isolate associated with staphylococcal food poisoning. Letters in applied microbiology, 65(1), 27-34.