Factors to Consider Before Tank Mixing Agrochemicals to Prepare the Spray Solution

This post is also available in:

This post is also available in:

![]() Ελληνικά (Greek)

Ελληνικά (Greek)

How to prepare a spray solution for pesticide application

Spraying is the most common method of applying Plant Protection Products (pesticides) to a crop, while it is also used to apply growth regulators, biostimulants, and nutritional products. Farmers prepare the spray solution by dissolving and stirring the pesticide in water according to the product label. Several parameters should be taken into account while preparing the solution. Mismanagement of the preparation leads to reduced effectiveness, the PPPs may not dissolve properly, and phytotoxicity problems may appear in the crop.

pH of the spray solution

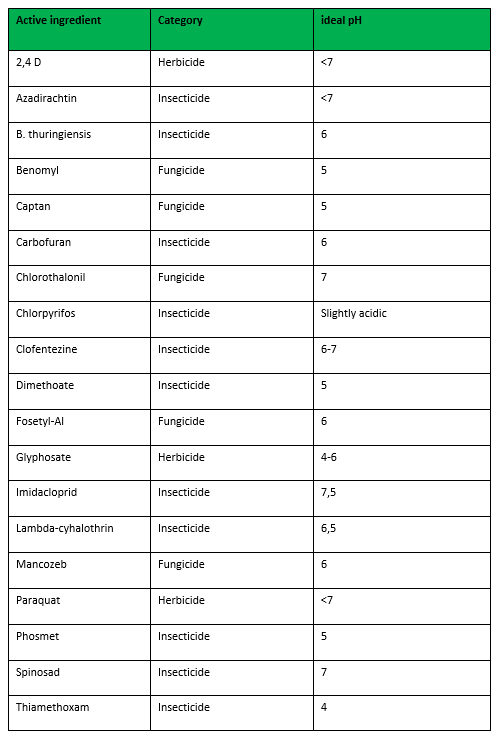

PH is an essential parameter in the successful application of a pesticide. The spray solvent is water, to which farmers add the pesticides. Water’s pH depends on its origin and usually varies between 6,5 – 9,5. Most pesticides are more effective in acidic solutions. In an alkaline environment, half-life (the time it takes for half the amount of active agent to react) is reduced, so their effectiveness is also limited (1, 2). The fungicide Captan is a typical example, whose half-life from 32 hours at pH 5 drops to 2 minutes at pH 9 (Table 1). Two large chemical groups of insecticides, organophosphates and carbamates, undergo alkaline hydrolysis at high pH, reducing their effectiveness. However, some pesticides are more effective in an alkaline environment, such as sulfonylurea herbicides (e.g. Chlorsulfuron) and the insecticide imidacloprid. Farmers need to know the alkalinity of the water they use for spraying, whether it’s from an irrigation network, borehole, or rainwater collection. There are three ways to know the pH value of water:

- By sending a water sample to an analytical lab

- With pH-metric paper

- Use of a pH meter

Spraying buffer agents are available on the market and producers can purchase them for pH adjusting. Some of them also contain an indicator so that the color of the solution changes when it reaches an ideal pH value, facilitating their use.

Table 1. Some active substances as well as the ideal pH of the solution (3, 4, 5).

Pesticide compatibility

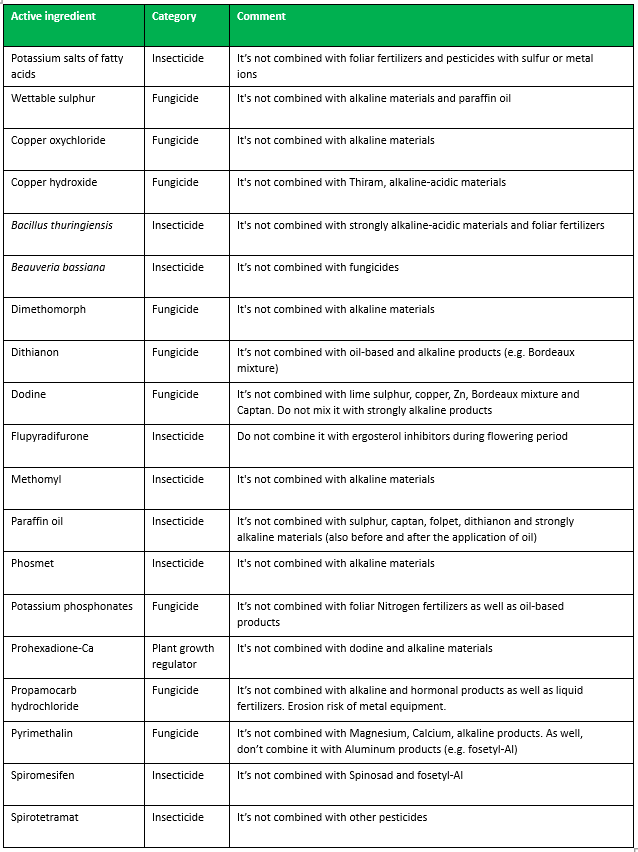

In a growing season, the needs for plant protection and foliar nutrition may coincide. Farmers can apply the different agents simultaneously in the same spray solution to save time and costs from several passes. For example, an insecticide, fungicide, foliar fertilizer, and surfactant may all coexist in a spray tank at the same time. However, the combination of pesticides poses some risks as the reduced effectiveness of the active substances or the creation of “synergistic” phytotoxicity in the crop. The mixing of the products should be done based on the instructions on the label and in the correct order (see next paragraph). It is helpful for growers to conduct a small-scale experiment in a clear container, mixing the desired products in the proportions they will use in the field. In the mixing, they may discover sedimentation, aggregation, insolubility, or gelling. Spraying with an unmixed solution is ineffective as the molecules of the active substances are undissolved in the water and there is a risk of clogging the sprayer’s nozzles. Chemically, the incompatibility of pesticides is due to a possible reaction between the active molecules or to the change in pH that can be caused in the solution (as mentioned above).

Table 2. Active substances and comments on their combinability with other pesticides. (source: Product labels).

Preparing the spray solution, the order of mixing

When different types of pesticide products are combined, the stirring’s order must be specific to achieve complete and uniform dissolution. The correct order of preparation of the spray solution is as follows:

- Filling the barrel up to 2/3 with water

- Water-soluble bags

- Wettable / Soluble Granules (WG, DF, SG)

- Wettable / Soluble Powders (WP, SP, WSP)

- Fill with water

- Aqueous solutions (WSC, SL)

- Suspension Concentrate (SC, FLOW)

- Emulsifiable liquids / Oil emulsions (EC)

- Surfactants, Adhesives, Oils

- Water-soluble fertilizers

(6, 7)

Note: For each addition of a formulation, we wait for its complete mixing and dispersion. Pre-diluting the formulations in a pot before adding them to the tank is also helpful. During the preparation of the spray solution, all protective measures must be taken as the pesticides are in high concentration, and due to agitation, the risk of contact is high.

References

(1) https://extension.missouri.edu/publications/ipm1017

(3) https://www.canr.msu.edu/news/effect_of_water_ph_on_the_stability_of_pesticides

(4) https://www.bctfpg.ca/resources/reference/pesticide-resistance-management/

(5) Table of ideal pH for active ingredients, Arysta LifeScience Corporation

(6) https://edis.ifas.ufl.edu/publication/PI285

(7) Table of instructions for preparing a spray solution, DuPont

Further reading