Factors Affecting the Quality of Olive Oil

This post is also available in:

This post is also available in:

![]() Français (French)

Français (French) ![]() Deutsch (German)

Deutsch (German) ![]() Türkçe (Turkish)

Türkçe (Turkish) ![]() Ελληνικά (Greek)

Ελληνικά (Greek)

The factors that affect the quality of olive oil can be found at all stages from its formation in the fruit until it reaches the final consumer.

- During the accumulation of the olive oil in the fruit, the factors that affect the quality are

-The variety

-The climate: In areas with a lot of sunshine, the aromatic ingredients and the quality of the olive oil are favored.

-The soil: In wet and clay soils, olive oil is less rich in aromatic components compared to dry and calcareous ones.

- From the accumulation of the olive oil in the fruit to the moment of harvest, the factors that affect quality are

-Insects: The main pest is the olive dacus (Dacus oleae, Bactoceraoleae). The holes created when the insect exits the fruit serve as future sources of infection. In these spots, fungi can also grow and secrete lipolytic enzymes that increase the acidity of the olive oil, which is not desirable. Finally, through these holes, the oxidation of the olive oil is favored, since it comes in contact with the atmospheric air. The various cocoides, such as the “black scale”, also contribute to the quality degradation of the olive oil.

-Fungi: Gleosporium olivarum causes significant changes, while Macrofoma dalmatica and Cycloconium oleaginum also harm the olives but in less extent.

-Harvesting time: The ideal time to harvest is considered to be the stage of the fruit’s normal ripening, i.e. when the color of the fruit changes from green-yellow to black-violet.

-The means of harvest: Injuring the fruit during harvesting essentially creates future sources of infection and fungal growth. Thus, the use of olive nets is recommended, since as a method it contributes to the reduction of collection costs and to the improvement of the quality of the olive oil. Growers should always keep in mind that fallen fruit has to be immediately removed from the ground.

- When storing the fruit before processing, the factors that affect the quality are

-The means of transporting the olive fruit: The fruits should not remain in the olive nets for long periods of time after their harvest, exposed to the sun and heat, as this may cause sunburns. Plastic crates are an ideal transport option, as they allow the fruit to aerate and breathe. After being placed in the crates, the fruit must be stored temporarily in a cool place, protected from heat and weather.

-The storage time before processing: As this time increases, the aromatic components of the olive oil and its resistance to oxidative rancidity decrease.

- When processing the fruit

It has been determined that the quality of the olive oil is formed by 25-30% in the olive mill. Therefore, the importance of the factors that affect the quality of olive oil during this stage is clear. The factors are

-Atmospheric air: Its contact with the olive paste causes oxidative deterioration of the olive oil.

-Temperature: High temperatures enhance chemical and biological changes.

-Iron on metal surfaces: Acts as an oxidation catalyst.

- When storing olive oil

During this stage, the quality of the olive oil can be significantly degraded under the influence of oxygen, temperature, light, metals, etc. More specifically:

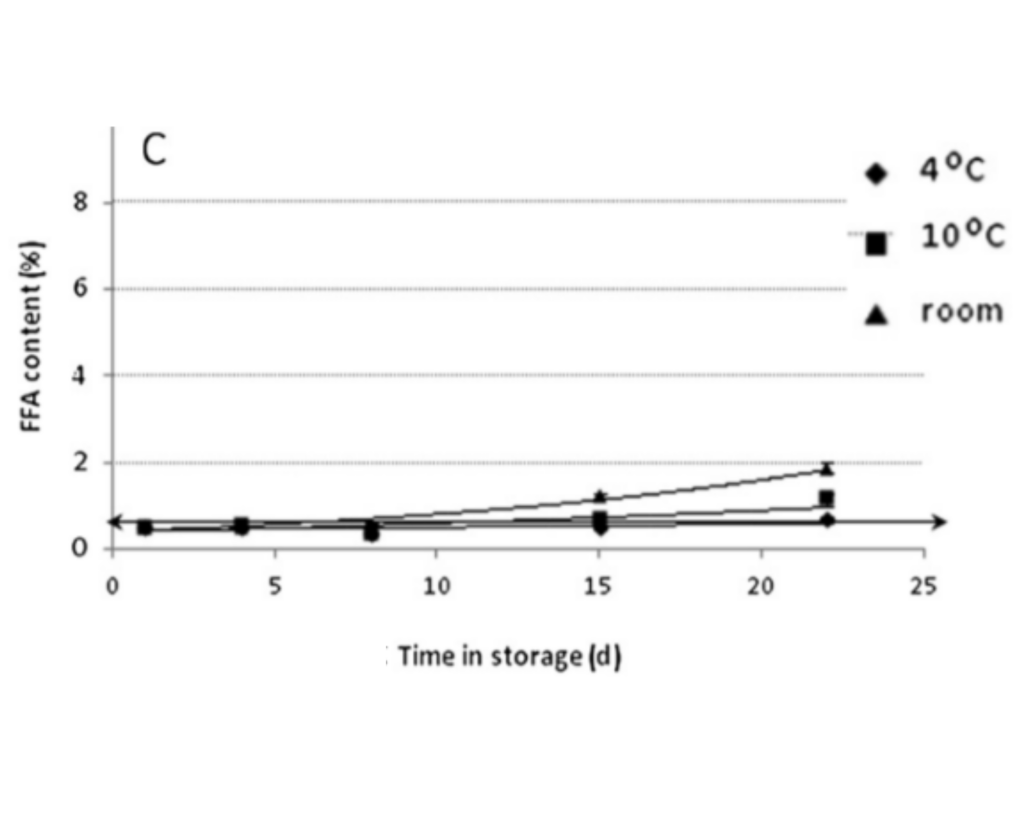

With increasing temperature

-the percentage of free fatty acids increases and

-acidity increases.

As shown in the graph below, as the storage time increases (horizontal axis), the acidity (vertical axis) increases too. This increase is more intense at higher temperatures, for example room temperature (curve with triangles), than at 10 °C (curve with squares) or 4 °C (curve with diamonds).

With exposure to oxygen

-the number of peroxides increases,

– the values K232, K270 and

-the concentration of phenolics decreases.

As shown in the graph below, as storage time increases (horizontal axis), phenolics decrease (vertical axis). This decrease is more pronounced at higher temperatures, for example room temperature (curve with triangles), than at 10 °C (curve with squares) or 4 °C (curve with diamonds).

Many producers use N2 gas as a means of filling their tanks in order to avoid these alterations.

References