Distillation of Sweet Basil for Essential Oil

Essential oils of aromatic plants are mostly obtained by distillation of various plant parts such as leaves, flowers, roots, bark, etc. As these essential oils are lighter than water, they float on the water after a distillation process and render easy separation and collection. To maximize the yield of essential oil, the farmer needs to pay attention during the extraction of the essential oil and during the sweet basil cultivation.

The distillation process could essentially be of two types:

- Water and steam distillation: The main parts are the still, condenser, receiver, and calendria. Steam is produced in a field distillation unit wherein water is boiled in the unit where the plant material is separated by a grid. The steam thus formed passes through the plant material carrying with it the essential oil along to a water-cooled condenser (check the picture above). In a collection vessel, both essential oil and water are collected. Essential oil is lighter than water, forms a layer on the top, and can be easily physically separated.

- Steam distillation: The main parts are the still, condenser, receiver, and boiler. Steam is produced in a separate boiler connected to the distillation vessel where the plant material is loaded. The essential oil is distilled in the same process described in the above part. However, the pressure of the steam could be manipulated, while in the earlier method, the steam was produced at atmospheric pressure.

Picture 1. Steam distillation equipement

In small farms where the quantities are smaller and if the farmer wants to invest less money in the distillation equipment, the first method using a field distillation unit is preferred as it is economical. If the area under the crop is large and continuous distillation is required, a distillation set-up using a steam boiler is recommended. Generally, the recovery and quality of essential oils obtained in both methods are similar.

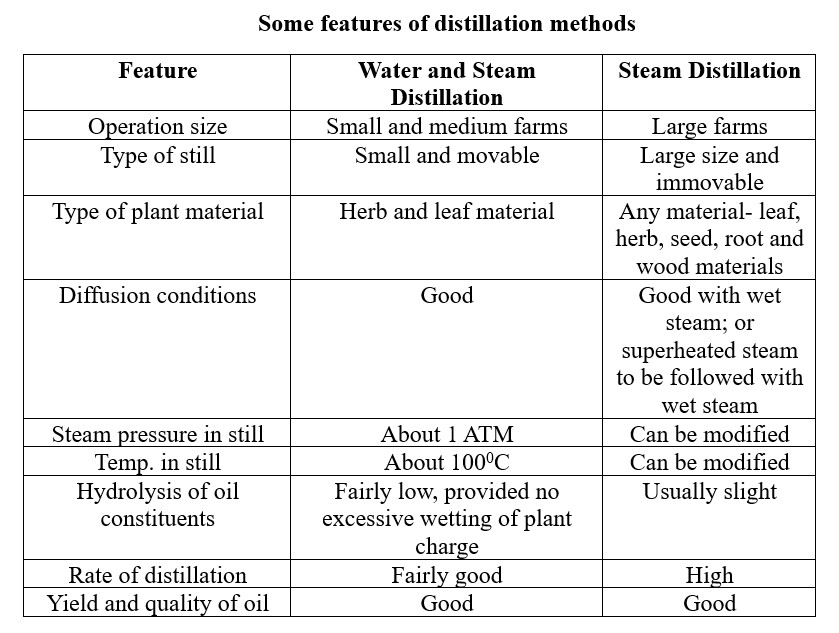

The various features of the two types of distillation of essential oils are presented in the table below:

In sweet basil, the essential oil is contained in the leaves. In field conditions, the plant herb is used for distillation; separation of leaves is not recommended. However, as the stem portion does not contain essential oil, it should be avoided. When harvesting the crop, the farmer is advised to collect only the tender herb portion, leaving the hard stems behind. Sometimes, even after the harvest, hard stems and branches should be separated and removed to the extent possible before loading the herb into the distillation vessel.

Sweet basil herb is partially wilted /dried under shade before the distillation. The distillation duration is 2.5 to 3.0 hours for obtaining optimum oil recovery. The oil recovery ranges between 0.4-0.6% with an average of 0.5%. In the first harvest, the oil content may be a little more than 0.4%, and in the ratoon crops, it could be 0.5-0.6%. This is due to low herb yields in the ratoon crops, which consist mainly of leaf portions. If 1 ton of sweet basil herb is distilled, an oil yield of 4-6 kg can be expected. Thus, a total basil oil yield from three harvests could be 100-120 kg/ha (40-50 kg/acre). The main, first, and second ratoon crops of sweet basil yield 50% (50-60 kg/ha), 30% (30-40 kg/ha), and 20% (20-25kg/ha) of the total oil yield, respectively.

Post-distillation actions: After the essential oil is separated from the water and collected, some water will still remain. Contact with water results in the deterioration of the essential oil. The remaining water should be removed using a separating funnel (2).

Picture 2. Separating funnel

Then, the associated moisture in the essential oil is removed by mixing it with 4% anhydrous sodium sulfate and filtered to obtain a clear essential oil. The oil thus obtained is stored in air-tight containers made of aluminum, glass, stainless steel, or HDPE. The oil is stored in a dark place. Any contact with water, air, or sunlight can spoil the quality of the essential oil.

Quality of sweet basil oil

The major chemical constituents determine the quality of sweet basil oil. They are analyzed by gas chromatography (GC/GC-MS) in a quality testing laboratory. The major chemical constituents of sweet basil oil discussed in this article are methyl chavicol (60-70%) and linalool (22-30%)(1). Methyl chavicol and linalool are negatively correlated. Application of N fertilizers increases the concentration of methyl chavicol and reduces linalool concentration in sweet basil oil (1). However, there are several chemotypes of sweet basil with a wide array of chemical constituents such as camphor, limonene, 1,8-cineole, linalool, geraniol, eugenol, methyl eugenol, estragole, methyl-cinnamate, etc. The European sweet basil, which contains methyl chavicol and linalool as major chemical constituents, is largely marketed in trade.

Further reading:

Commercial Cultivation of Sweet Basil (Ocimum basilicum) for oil production

Distillation of Sweet Basil for Essential Oil

Patchouli cultivation guide – How to grow Patchouli Commercially for oil

References

- Prakasa Rao, E.V.S., K. Puttanna, R.S.Ganesha Rao and S. Ramesh (2007). Nitrogen and potassium nutrition of French basil (Ocimum basilicum Linn.). J. Spices and Aromatic Crops, 16(2), 99-105.

- https://stock.adobe.com/in/search?k=%22separating+funnel%22&continue-checkout=1

Further reading

Patchouli cultivation guide – How to grow Patchouli Commercially for oil

Distillation of patchouli for essential oil – Patchouli essential oil extraction

Commercial Cultivation of Sweet Basil (Ocimum basilicum) for oil production

Distillation of Sweet Basil for Essential Oil