Distillation of patchouli for essential oil – Patchouli essential oil extraction

Predistillation process of patchouli – How to handle patchouli for extracting oil

Patchouli is mainly cultivated for its valuable essential oil. After cultivating patchouli for oil production the farmer-professional should follow specific steps and principles to obtain the maximum amount of patchouli oil of the highest quality.

As in many aromatic crops, the Patchouli herb is not distilled as a fresh herb soon after harvest. The patchouli herb consisting of leaves and tender twigs, is dried for a few days to reach 15-20% moisture, meaning the dry herb will be around one-fifth of the fresh herb (1). Care should be taken to avoid harvesting mature/hard stem portions since they do not contain oil and result in low oil recovery and a high cost of distillation. Depending on the climate, the drying process may take up to 1 week. Many farmers dry patchouli herbs under open conditions (2). Avoid drying patchouli herbs in the open, as rain and sunshine will deteriorate the quality of the herb and reduce oil recovery. The herb is preferably dried in sheds protected from direct sunlight and rain. Low-cost temporary sheds can be erected on the farmers’ fields (1). During drying, the herb is turned over to avoid deterioration of the herb’s quality. The dried herb can be stored for weeks/months if kept in well-protected store with cool temperatures and aeration. Thus farmers can dry the patchouli herb and store it for some time before distillation or transportation to the distillation factory.

Patchouli herb being dried in the open

Patchouli herb being dried in the open

A low cost-structure for drying patchouli herb

A low cost-structure for drying patchouli herb

Distillation of patchouli oil – Extracting patchouli essential oil

Essential oils of aromatic plants are mostly obtained by distillation of various plant parts such as leaves, flowers, roots, bark, etc. As these essential oils are lighter than water, they float on the water after such a distillation process and render easy separation and collection. The distillation process could essentially be of two types:

1. Water and steam distillation: The main parts are the still, condenser, receiver, and calendria. Steam is produced in a field distillation unit wherein water is boiled in the unit where the plant material is separated by a grid. The steam thus formed passes through the plant material carrying with it the essential oil along to a water-cooled condenser. In a collection vessel, both essential oil and water are collected. Essential oil is lighter than water, forms a layer on the top, and can be physically separated.

Water and steam distillation unit

Water and steam distillation unit

2. Steam distillation: The main parts are the still, condenser, receiver, and boiler. Steam is produced in a separate boiler connected to the distillation vessel in which the plant material is loaded. The essential oil is distilled in the same process described in 1. However, the pressure of the stem could be manipulated, while in the earlier method, the steam was produced at atmospheric pressure.

Steam distillation unit

Steam distillation unit

In small farms where the quantities are small and if the farmer does not invest much in the distillation equipment, the first method using a field distillation unit, is preferred as it is economical. If the area under the crop is large and continuous distillation is required, a distillation set-up using a steam boiler is recommended. Generally, the recovery and quality of essential oils obtained in both methods are similar. In the case of patchouli, the steam distillation method is preferred so as to derive better oil recovery and quality and to increase the rate of distillation (1).

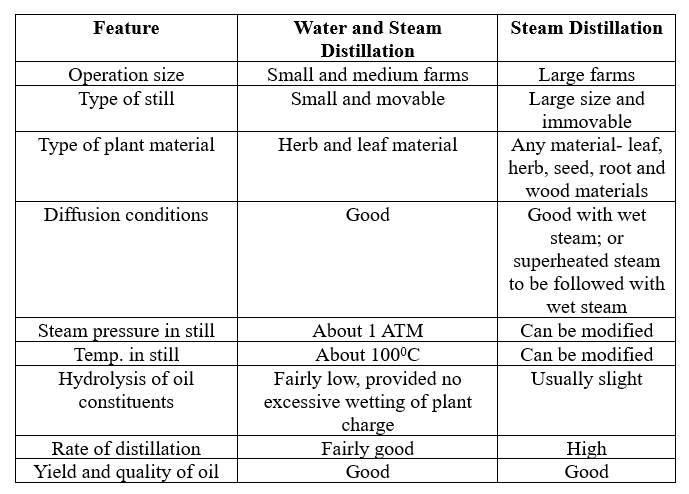

The various features of the two types of distillation of essential oils are given in the table below:

Some features of distillation methods

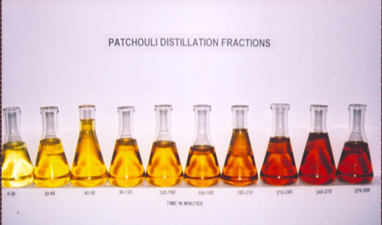

Patchouli is distilled for a period of 6-8 hours. At the beginning of the distillation, lighter fractions of patchouli oil are distilled, followed by heavier fractions (see below).

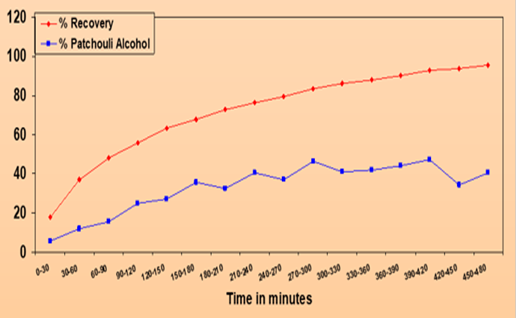

The oil recovery increases gradually with time and peaks between 6-8 hours. The initial oil fractions contain less patchouli alcohol, and it increases to optimum concentrations by about 4 hours. An oil recovery of 2.0-2.5% can be expected. If 1 ton of air-dried patchouli herb is distilled, 20-25 kg of patchouli oil can be expected. In one ha of land, 60-100 kg of patchouli oil can be expected in 2 harvests, about 25-40 kg per acre.

Patchouli oil recovery and patchouli alcohol content at the time of distillation

Post-distillation: After the essential oil is separated from the water and collected, some water will still remain. Contact with water results in the deterioration of the essential oil. The remaining water should be removed using a separating funnel.

Separating funnel

Separating funnel

Then, the associated moisture in the essential oil is removed by mixing it with 4% anhydrous sodium sulfate (40g/lit) and then filtered to obtain a clear essential oil. The oil thus obtained is stored in air-tight containers made of aluminum, glass, stainless steel, or HDPE. The oil is stored in a dark place. Any contact with water, air, or sunlight can spoil the quality of the essential oil. Unlike many essential oils, patchouli oil can be stored long if the above precautions are taken.

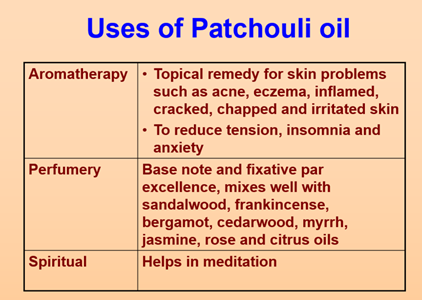

Uses of patchouli oil

Patchouli oil quality:

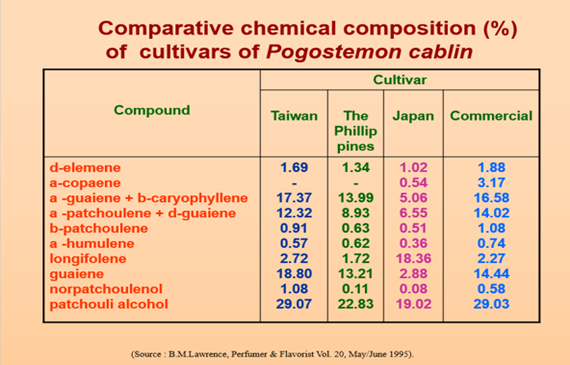

The chemical composition of patchouli oils from various regions is given below (3).

Chemical composition of patchouli

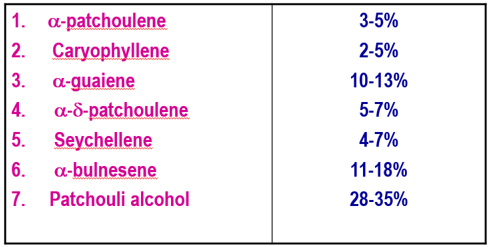

A typical patchouli oil produced in south India has major chemical constituents as given below (1).

Patchouli alcohol is the marker compound in the oil. The international standard for patchouli alcohol in patchouli oil is 25-30%.

The oil quality is not adversely affected if grown in an open or shade (4) or by applying organic manures or biofertilizers (5,6).

References:

- Prakasa Rao, E.V.S. (2014). Technology for the production of patchouli oil. Training programme on commercial cultivation of medicinal and aromatic plants. Central Institute of Medicinal and Aromatic Plants, Research Centre, Bengaluru, India.

- Feri Agustian Soleh (2012). astiri-indonesia.org

- Lawrence, B.M. (1995). Perfumer& Favorist. 20, May/June 1995.

- Prakasa Rao, E.V.S., R.S.Ganesha Rao, M. R. Narayana and S. Ramesh (1997). Influence of shade on yield and quality of patchouli (Pogostemon cablin) oil. Indian Perf. 41(4): 164-166.

- Arpana, J., Bhagyaraj, D.J., Prakasa Rao, E.V.S., Parameswaran, T.N., Abdul Rahiman, B., (2008). Symbiotic response of patchouli (Pogostemon cablin) to different arbuscular mycorrhizal fungi. Adv. Environ. Biol. 2 (1), 20–24.

- Singh, R., Singh, M., Srinivas, A., Prakasa Rao, E.V.S., Puttanna, K. (2015). Assessment of organic and inorganic fertilizers for growth, yield and essential oil quality of industrially important plant patchouli (Pogostemon cablin) (Blanco) Benth. Essent. Oil Bear. Pl. 18 (1), 1–10.

Further reading

Patchouli cultivation guide – How to grow Patchouli Commercially for oil

Distillation of patchouli for essential oil – Patchouli essential oil extraction

Commercial Cultivation of Sweet Basil (Ocimum basilicum) for oil production