Aflatoxin Contamination of Pistachio nuts

Aflatoxin Contamination of Pistachio nuts: pathways, control measures and the effect on the nutritional quality

Pistachio nuts, characterized by a pale greenish kernel with a taste reminiscent of almonds, possess wholesome qualities and significant nutritive value. The pistachio tree contributes more than just nuts to society; its oil is used for cooking and flavouring desserts. Nuts play a vital role in the human diet due to their high fibre, protein, low cholesterol, and antioxidant content. Additionally, they contain polyunsaturated and monounsaturated fats linked to healthy cholesterol levels, reducing the risk of heart disease. Pistachios promote healthy gut bacteria, lower blood pressure and cholesterol levels, improved blood vessel health, and better eye health.

The top pistachio-producing countries—namely, the US, Iran, and Turkey—account for 97% of the world’s pistachio nuts. The US is the leading producer and exporter, followed by Iran and Turkey. The pistachio industry has become increasingly competitive due to rising consumption, leading countries with suitable cultivation conditions to establish new orchards. Despite efforts in countries like Syria, Greece, Italy, and Spain, their production rates often fall short of domestic demands, necessitating imports from major producers like the US and Iran. Unfortunately, these valuable and nutritious seeds are vulnerable to fungal attacks, resulting in the production of toxic chemicals known as mycotoxins. A group of these chemicals, called aflatoxins, is produced by Aspergillus flavus. Aflatoxins are carcinogenic, and Aspergillus flavus is widely distributed in temperate, sub-tropical, and tropical climates globally. Aflatoxins may be produced both before and after harvest, particularly in oilseeds, edible nuts, and cereals. Considering the health hazards posed by molds and the toxins they produce in food and feed, a laboratory study was conducted on the contamination of pistachio nuts with Aspergillus flavus, aiming to assess the nutritional quality of the nuts. Before delving into the details of how Aspergillus flavus contaminates pistachio nuts and identifying common molds during fungal counts after contamination, it is essential to understand their classification in microbiology. The main focus of this study was on Aspergillus flavus and its related toxins, aflatoxins. Aspergillus flavus is a mycotoxigenic fungus with the ability to produce B aflatoxins. Morphologically, it can be readily distinguished by the bright yellow-green conidial color when cultured on malt extract agar or Czapek yeast extract agar. It is widely reported as a food-borne fungus and is one of the dominant species found on stored products.

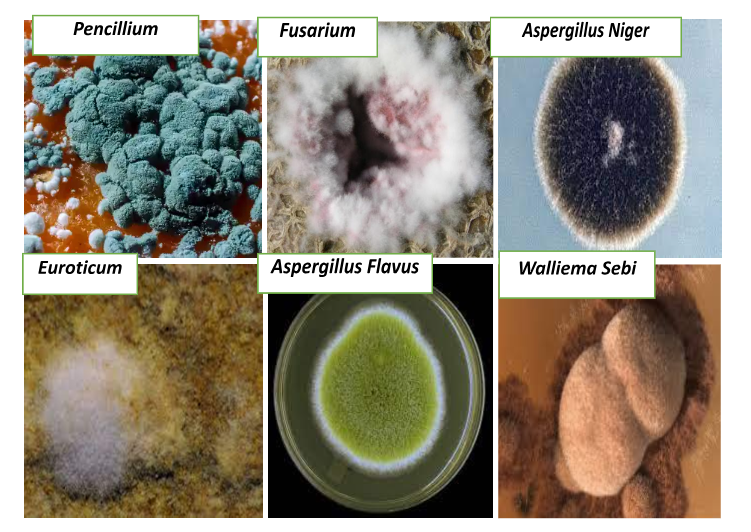

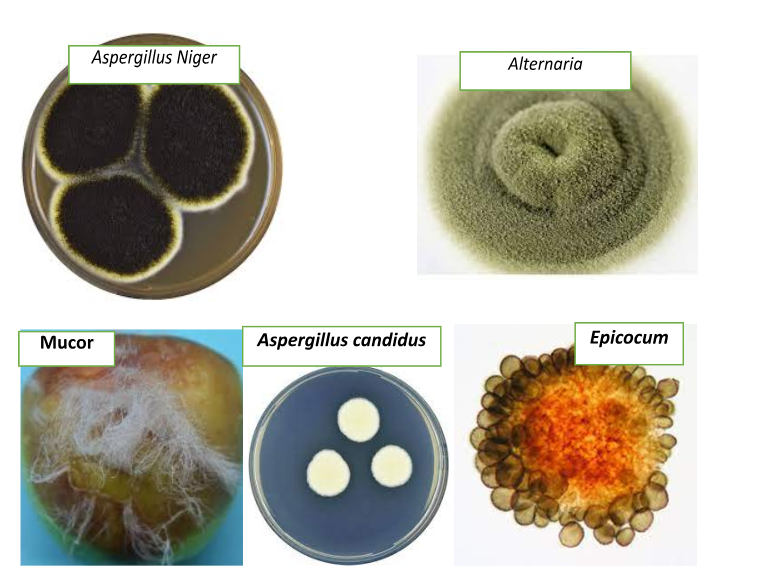

The following were the common molds counted after incubation at 30°C of the pistachio nuts.

Nutritional Facts of Pistachio Nuts

Iran holds the top position globally in pistachio production, boasting a diverse population of wild pistachios and numerous cultivated varieties. According to the Agriculture Ministry of Iran in 2011, the country produced over 220,000 tons of pistachio nuts. Renowned for their high nutritional value, pistachio kernels are rich in protein, fats, and particularly essential unsaturated fatty acids. Additionally, pistachios are a valuable source of vitamins and minerals, including vitamins A, E, B1, B6, and folate, along with essential minerals such as iron, phosphorus, and zinc.

Nutritional Quality of Pistachio nuts before and after contamination with Aflatoxin

Incubated at 30°C, samples from three distinct cultivars of pistachio nuts underwent fungal count analysis. After disinfection with bleach, these samples were inoculated with Aspergillus flavus (isolated from local peanut samples) to assess aflatoxin (B1, B2, G1, and G2) contamination through HPLC. Subsequent alterations in proximate composition, mineral content, and fatty acids were examined. The dominant contaminants identified in the pistachio samples included Penicillium, Euroticum, Fusarium, Walliema, Sebi, Alternaria, Aspergillus niger, Aspergillus Ocharacious, Aspergillus Candidus, Aspergillus flavus, Mucor, Yeast Epicoccum. Inoculated A. flavus samples exhibited increased B1, B2, G1, and G2 compared to the control (not infected). During inoculation, a decrease in crude protein and crude fat was observed, while ash showed a positive effect. Fiber remained unaffected, nitrogen-free extract (NFE) increased, and moisture also increased due to the addition of spores in solution form.

Fungal inoculation significantly impacted the fatty acids contents, with an increase in palmitic and stearic acids and a decrease in oleic and linoleic acids. Changes in mineral content revealed decreases in Pb, Se, Cu, Mn, and K, while Cd, Ca, Mg, Cr, Zn, Fe, Na, and P increased during inoculation. The study concluded that the growth of A. flavus and aflatoxin production had a noteworthy effect on the substrate’s chemical composition. Modifying certain constituents genetically or chemically may reduce aflatoxin production, offering a potential strategy for aflatoxin risk management.

The research holds significance in aflatoxin prevention strategies, suggesting that alterations in composition, whether genetic or chemical, could impact Aspergillus attraction patterns and toxin production, offering an effective approach to toxin risk management. Recent findings indicated the ability of various compounds to induce aflatoxin biosynthesis, with some compounds inducing aflatoxin production while others, like peptone, did not support it. Feeding on aflatoxin-contaminated corn affected serum Ca, K, and glucose levels, and the addition of clay impacted Mg and Na absorption. Evaluations of minimal moisture content for growth and aflatoxin production by A. parasiticus demonstrated a dependency on both moisture content and time duration.

Factors affecting the Aflatoxin contamination in Pistachio Nuts

The challenge posed by Aspergillus species and their mycotoxins in contaminating pistachio nuts is significant for the global production, consumption, and exportation of pistachios. Strains of Aspergillus flavus and A. parasiticus, known for producing aflatoxins, are widespread in soil and air, acting as both field and storage molds. This adaptability to diverse geographical conditions allows them to disperse through air-borne and soil-borne conidia, causing infections in various crops and their products before and after harvest, ultimately leading to aflatoxin production.

Infection and aflatoxin production in pistachio kernels are influenced by ecological and biological requirements. Factors such as plant litter, animal manures, nut cracking, environmental conditions, cultural practices, irrigation frequency, and harvesting dates are identified as crucial contributors. Effective post-harvest handling, transportation, and storage are essential to mitigate the risk of contamination.

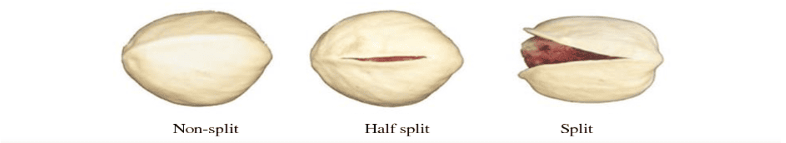

The association between A. flavus infection in pistachios and the frequency of early splits, where hulls split before nut maturity, is noteworthy. Spore density and reproduction show a positive correlation with the maturation period of pistachio nuts during spring and summer, emphasizing the importance of aligning peak spore density with the nut harvesting period. Early harvesting has proven to be a critical strategy in reducing aflatoxin levels in pistachios.

The nutrient balance, particularly for iron and its ratios with zinc, magnesium, and copper, significantly impacts the formation of early splits in pistachio nuts. The choice of processing units, whether mechanized or traditional, affects Aspergillus density on pistachios, cross-contamination, and the efficiency of separating contaminated nuts during processing. Mechanized processing plants are preferred for their efficiency.

How to prevent aflatoxin contamination in Pistachio nuts – Control measures and management of aflatoxin contamination

Several factors impact the prevalence of aflatoxin during distinct stages: before harvest, at harvest, and after harvest. In the pre-harvest phase, essential measures include controlling climatic conditions and soil factors, preventing infestation by insects and birds, avoiding drought stress, managing plant pathogens, monitoring water activity, and ensuring pistachios reach maturity. Key factors during harvesting encompass optimal timing, careful transportation, preventing mechanical damage to kernels, and timely drying of pistachios. Post-harvest, crucial aspects influencing aflatoxin contamination involve storage conditions, kernel moisture content, drying duration, segregating contaminated pistachios before storage, and maintaining hygienic conditions. Therefore, the integral aspect of minimizing the risk of aflatoxin contamination in pistachios lies in controlling and eliminating aflatoxigenic fungi. Creating awareness among farmers and consumers regarding aflatoxin-producing fungi and the incidence of contamination in pistachios is vital for public health, especially in pistachio-producing regions. Accumulating knowledge and fostering positive attitudes, along with implementing effective practices to control exposure to this hazard, play a crucial role in ensuring the safety of pistachios.

Numerous endeavors have been undertaken to manage aflatoxin contamination in various crops, employing diverse methods. While no single approach has been entirely successful, the use of atoxigenic strains of A. flavus, yeast, and bacterial strains has shown promise. This strategy involves employing competitive biological control agents to reduce the population of toxigenic strains in soil or plant litter, subsequently decreasing infection rates of nuts and aflatoxin levels in pistachios before and/or after harvesting.

The findings indicate that pistachio nuts are highly susceptible to Aspergillus flavus and other molds, as various molds infested the pistachios, with toxigenic Aspergillus species isolated from local farm peanuts. Aspergillus flavus can readily grow on pistachio nuts, leading to aflatoxin production. The capacity for toxin production and Aspergillus flavus growth depends on nutrient composition and physical structure, with early split nuts being more susceptible to Aspergillus flavus growth. Certain nutrients were observed to enhance toxin production, while others had a negative impact.

To mitigate the risk of aflatoxin production, it is crucial to test pistachio nut seeds for mold contamination and monitor moisture content. Open shell nuts should be stored in a moisture-free environment with great care, and toxin content should be regularly monitored in pistachio nuts, regardless of the presence of Aspergillus. Further research is recommended to explore chemical or genetic composition changes for toxin risk management. Incorporating certain metals and fatty acids during storage could potentially reduce the risk of toxin production.

According to the FDA, consistent intake of aflatoxin can heighten the likelihood of liver cancer, induce birth defects, and result in issues with kidneys and the immune system. Consuming a large quantity of aflatoxins in a single instance can even lead to liver failure and potentially be fatal. The severity of these health risks underscores why aflatoxins are treated with great concern. As professionals in the food industry, prioritizing the well-being and safety of our consumers is paramount. Since there is no effective processing step for a final product with aflatoxin residues, it is crucial to control and prevent this situation. The initial step in minimizing contamination involves gaining a comprehensive understanding of its underlying causes.

Early Split

The study revealed that the occurrence of early hull split has consistently been associated with an increased likelihood of aflatoxin development. This heightened risk is largely attributed to the hull-splitting process, which takes place as the pistachio completes its maturation cycle. Before the hull split, the shell completely covers the pistachio kernel, providing protection against exposure and a reduced vulnerability to mold and insect infestation. Once the shell is no longer fully encasing the pistachio, aflatoxin finds easier access to initiate the contamination process.

Environmental Factors

Aflatoxin is primarily disseminated by climate conditions. Aspergillus fungi thrive in warm and humid climates, causing the most damage to crops in the field, during harvest, and in storage post-harvest. The climate that supports the growth of these fungi is also the one necessary for most nut production, posing a challenge for growers. Additionally, drought stress is recognized for heightening the vulnerability of almonds and pistachios to fungal infection. Soil lacking sufficient water negatively impacts the defense mechanisms of plants, creating a conducive environment for aflatoxin production.

Insect Damage

The harm caused by insects facilitates conditions conducive to aflatoxin production by creating entry points for fungal growth. In the case of almonds and pistachios, the formidable Navel Orangeworm (Amyelois transitella) stands out as a major insect invader.

Adopting a proactive Integrated Pest Management (IPM) strategy, incorporating insecticide sprays. Minimize the presence of leftover mummy nuts post-harvest and execute an annual winter sanitation protocol. The California Department of Food and Agriculture (CDFA), in collaboration with the USDA, the California tree nut industry, and other stakeholders, established the Navel Orangeworm Program. This initiative aims to mitigate the damage caused by Navel Orangeworm in California. The program employs a comprehensive approach, incorporating the release of sterile Navel Orangeworm and other mating disruption techniques. It serves as a valuable resource for comprehending and reducing Navel Orangeworm populations.

Inadequate Storage Conditions

The main considerations for storage revolve around moisture and exposure to climate conditions. It is essential to avoid storage environments that are damp, warm, or humid to minimize the likelihood of fungal growth. Without proper storage practices, almonds and pistachio nuts face an increased risk of fungal infection. Store nuts in a cool, dry place to reduce the likelihood of fungal growth and aflatoxin development. It’s essential to note that aflatoxin flourishes in warm conditions, so ensure adequate ventilation to prevent this.

Good Agricultural Practices

Adopting effective agricultural practices, including proper irrigation, timely harvest, sorting, and disposal, along with utilizing non-toxic strains of Aspergillus flavus as biopesticides, is crucial for minimizing aflatoxin levels.

- Irrigation: Employing sound irrigation practices, such as maintaining optimal soil moisture levels, can mitigate the risk of drought stress and fungal infections.

- Timely Harvests: Avoiding delays in the harvest process is essential to prevent an escalation of aflatoxin contamination. Procrastination in harvesting correlates with increased aflatoxin incidence.

- Sorting and Disposal: Segregate contaminated nuts from uncontaminated ones to prevent cross-contamination. Dispose of contaminated nuts safely to avoid any potential exposure.

- Biocontrol: Applying strains of Aspergillus flavus, like AF 36, which do not produce aflatoxin, can be a biocontrol measure. These strains outcompete toxin-producing strains, thereby reducing the risk of contamination in the orchard.

Lab Testing from a USDA-Approved Laboratory

It is crucial to employ a USDA-certified laboratory for aflatoxin testing to identify contamination and prevent the distribution of unsafe products to consumers. These laboratories adhere to strict quality management systems and accreditation, guaranteeing the highest standards of analytical performance and competency. Collaborating with a certified lab instils confidence in producers regarding the accuracy of test results, enabling them to make informed decisions about the marketability and safety of their products.

Effects of Aflatoxin Contamination on Exports

Despite implementing these precautions, the presence of aflatoxin can still pose challenges to your export endeavors. When dealing with aflatoxins, the critical factor for successful exports is a thorough understanding of your requirements and tolerances. Both pistachios and almonds have dedicated programs aimed at addressing concerns related to aflatoxin contamination, ensuring the safety and quality of exported products. This involves compliance with specified limits for ppb total and AFB1.

PEAR Program

The PEAR (Pistachio Export Aflatoxin Reporting) program, established through collaborative efforts between industry experts and regulatory authorities in the early 2000s, introduces specific measures to meet the shipping standards accepted by European Union member states. These measures include defined shipping tolerance, mandatory sampling, testing of pistachio products exclusively in USDA-approved laboratories, and a thorough audit of the shipping process. Products meeting these criteria are issued the PEAR certificate of analysis (COA).

Methods to find Aflatoxin in Pistachio nuts

The verification method required is HPLC with fluorescence detection and preliminary sample extraction. Unfortunately, aflatoxins B1 and G1 exhibit minimal fluorescence, making them challenging to detect. To enhance sensitivity, the mixture of aflatoxins B1 and G1 is irradiated with UV light at 254 nm, causing photo-induced hydroxylation, enabling more sensitive measurement through fluorescence spectrometry. The dedicated AZURA Aflatoxin system includes a fluorescence detector with a coupled photochemical post-column derivatization module. This post-column derivatization process allows for non-toxic and rapid derivatization at room temperature. Unlike previous methods utilizing saturated iodine reaction coils or electrochemically generated bromine in a KOBRA cell, no toxic halogenic reagents are employed for derivatization. This eliminates the use of halogenic solvent waste. The complete analytical method, including recovery, standard deviation, and robustness evaluation, is detailed in AppNote VFD01787. The sample preparation outlined in this AppNote is designed to minimize intensive matrix effects, facilitating highly reproducible and sensitive quantification of aflatoxins.

Allowed level of aflatoxin in Pistachio nuts

Recently, there has been a heightened focus on the health risks associated with the consumption of aflatoxins (AFs) in food and feed. Numerous experimental, clinical, and epidemiological studies have been conducted, revealing adverse health effects in humans and animals exposed to AFs contamination, depending on the level of exposure. High-dose exposure to the contaminant can lead to symptoms such as vomiting, abdominal pain, and, in extreme cases, death, while chronic exposure to small quantities may contribute to the development of liver cancer. The International Agency for Research on Cancer (IARC) has classified both B- and G-type aflatoxins as Group 1 mutagens, while AF-M1 is classified in Group 2B. Additionally, AFs may have detrimental effects on child growth, and in conjunction with other mycotoxins, they are suspected of playing a role in edema development in malnourished individuals and the pathogenesis of kwashiorkor in malnourished children. Furthermore, AF contamination adversely affects crop and animal production, resulting not only in the wastage of natural resources but also in decreased market value, causing significant economic losses.

Due to these adverse effects, various countries and international organizations have implemented stringent regulations to control AF contamination in food and feed and restrict the trade of contaminated products. The regulations concerning “acceptable health risk” typically depend on a country’s economic development, the extent of consumption of high-risk crops, and the susceptibility of crops to contamination. The established safe limit of AFs for human consumption ranges from 4 to 30 μg/kg. The European Union (EU) has set the strictest standards, stipulating that any product for direct human consumption cannot be marketed with a concentration of AF-B1 and total AFs greater than 2 μg/kg and 4 μg/kg, respectively. Similarly, US regulations specify the maximum acceptable limit for AFs at 20 μg/kg. However, if the EU aflatoxin standard is universally adopted, lower-income countries in Asia and Sub-Saharan Africa will face economic losses and additional costs associated with meeting those standards. This situation necessitates the development of alternative technologies at pre- and post-harvest levels aimed at minimizing contamination of commercial foods and feeds, ensuring that AF levels remain below safe limits.

Innovative technologies for the Aflatoxin control or elimination

Utilizing innovative technologies is crucial in tackling the challenges associated with AFs and their consequences. Effectively reducing AF contamination through a comprehensive understanding of pre and post-harvest management represents an initial step in formulating a suitable strategy to enhance agricultural productivity sustainably. This, in turn, directly contributes to the improvement of food quality and nutritional value, the preservation of natural resources, and the promotion of local and international trade by bolstering competitiveness.

Identifying and documenting available technologies that can successfully control and minimize aflatoxin contamination is essential for sustaining healthy living and fostering socioeconomic development. A wealth of literature is available on tools for AF control and their associated benefits. The following review provides data on innovative pre- and post-harvest technologies that have been developed to manage AF contamination in foods. The advantages of these technologies concerning food security, human health, and economic value are also discussed. Ultimately, the review underscores the implications for research and management policies aimed at addressing AF-related issues.

References

Abdolshahi A, Marvdashti LM, Salehi B, Sharifi‐Rad M, Ghobakhloo S, Iriti M and Sharifi‐Rad J (2019) Antifungal activities of coating incorporated with Saccharomyces cerevisiae cell wall mannoprotein on Aspergillus flavus growth and aflatoxin production in pistachio (Pistacia vera L.). Journal of Food Safety. 39(2), e12608.

Abdolshahi, A., Shabani, A. A., Mortazavi, S. A., & Marvdashti, L. M. (2018). Aflatoxin binding efficiency of Saccharomyces cerevisiae mannoprotein in contaminated pistachio nuts. Food Control, 87, 17-21.

Abdolshahi, A., Tabatabaiee Yazdi, F., Shabani, A. A., Mortazavi, S. A., & Mohammadi Nafchi, A. (2016). Antifungal properties of gelatin-based coating containing mannoprotein from Saccharomyces Cerevisiae on Aspergillus flavus growth in pistachio. Journal of Mazandaran University of Medical Sciences, 26(139), 93-102.

AbdolshahiA, Yazdi FT, Shabani AA, Mortazavi SA, Nafchi AM (2016) Antifungal properties of gelatin-based coating containing mannoprotein from saccharomyces cerevisiae on aspergillus flavus growth in pistachio. Journal of Mazandaran University of Medical Sciences. 26(139), 93-102

Abdoshahi A, Mortazavi S, Shabani A, Elhamirad A , Taheri M (2011) Evaluation of protein, fat and fatty acids content of the pistachio (Pistacia vera L.) cultivars of Damghan, Iran. Journal of Nuts. 2, 15-24.

Abdoshahi, A., Mortazavi, S. A., Shabani, A. A., Elhamirad, A. H., & Taheri, M. (2011). Evaluation of protein, fat and fatty acids content of the pistachio (Pistacia vera L.) cultivars of Damghan, Iran.

Aflatoxin Guide for Almonds and Pistachios – Safe Food Alliance

Afshari H, Hokmabadi H (2011) Recognition and Determination of Contaminated Pistachios to Aflatoxin in Processing Stage. Journal of Nuts. 2(2), 27-30

Aldars-García L, Ramos AJ, Sanchis V, Marín S (2015) An attempt to model the probability of growth and aflatoxin B1 production of Aspergillus flavus under non-isothermal conditions in pistachio nuts. Food Microbiology. 51, 117- 129.

Cheraghali A, Yazdanpanah H, Doraki N, Abouhossain G, Hassibi M, Ali-Abadi S, Aliakbarpoor M, Amirahmadi M, Askarian A, Fallah N (2007) Incidence of aflatoxins in Iran pistachio nuts. Food and Chemical Toxicology. 45(5), 812- 816

de Laat, B., & Williams, K. (2013). EUROPEAN COMMIssION (EC). Enhancing Evaluation Use: Insights from Internal Evaluation Units, 147.

de Laat, B., & Williams, K. (2013). EUROPEAN COMMIssION (EC). Enhancing Evaluation Use: Insights from Internal Evaluation Units, 147.

Dearborn, D. G., Smith, P. G., Dahms, B. B., Allan, T. M., Sorenson, W. G., Montana, E., & Etzel, R. A. (2002). Clinical profile of 30 infants with acute pulmonary hemorrhage in Cleveland. Pediatrics, 110(3), 627-637.

Disterhoft, J. F., Coulter, D. A., & Alkon, D. L. (1986). Conditioning-specific membrane changes of rabbit hippocampal neurons measured in vitro. Proceedings of the National Academy of Sciences, 83(8), 2733-2737.

Fani S, Moradi M, Zamanizadeh H, Mirabolfathy M, Probst C (2014) Distribution of nontoxigenic strains of Aspergillus flavus throughout pistachio growing areas in Iran. Applied Entomology and Phytopathology. 81(2), 179- 189.

Folmert, K., Losch, C., & Monks, K. (2022). ULDC–Effects of extra column volume and extra column dispersion. LC-GC Europe, 35(6).

Fung, F., & Clark, R. F. (2004). Health effects of mycotoxins: a toxicological overview. Journal of Toxicology: Clinical Toxicology, 42(2), 217-234.

Goldblatt L (2012) Aflatoxin: scientific background, control, and implications. Elsevier; 2012 Dec 2. New York and London. 13-46.

Hendrickse, R. G., Coulter, J. B., Lamplugh, S. M., Macfarlane, S. B., Williams, T. E., Omer, M. I., & Suliman, G. I. (1982). Aflatoxins and kwashiorkor: a study in Sudanese children. British medical journal (Clinical research ed.), 285(6345), 843.

Hibbett, D. S., Binder, M., Bischoff, J. F., Blackwell, M., Cannon, P. F., Eriksson, O. E., … & Zhang, N. (2007). A higher-level phylogenetic classification of the Fungi. Mycological research, 111(5), 509-547.

Holakouie Naieni, K., Ghods, B., Ghorbani, R., Bagheri, B., & Abdolshahi, A. (2020). Aflatoxin contamination of pistachio and aflatoxicose: Knowledge, attitude, and practices of people in Damghan City, Iran. Journal of Nuts, 11(1), 91-99.

Juan, C., Ritieni, A., & Mañes, J. (2012). Determination of trichothecenes and zearalenones in grain cereal, flour and bread by liquid chromatography tandem mass spectrometry. Food chemistry, 134(4), 2389-2397.

Kabirian, H. R., Afshari, H., MOHAMMADI, M. M., & Hokmabadi, H. (2011). Evaluation of pistachio contamination to Aspergillus flavus in Semnan Province.

Kendra, D. F., & Dyer, R. B. (2007). Opportunities for biotechnology and policy regarding mycotoxin issues in international trade. International Journal of Food Microbiology, 119(1-2), 147-151.

Kylene Rodriguez., (2005). Nutritional Differences of Pistachio Nuts and Pistachio Butter. NTRS., 519, Summer

Magan N, Aldred D (2007) Post-harvest control strategies: minimizing mycotoxins in the food chain. International Journal of Food Microbiology. 119(1-2), 131-139.

Magan N, Aldred D (2007) Post-harvest control strategies: minimizing mycotoxins in the food chain. International Journal of Food Microbiology. 119(1-2), 131-139.

Magan, N., & Aldred, D. (2007). Post-harvest control strategies: Minimizing mycotoxins in the food chain. International journal of food microbiology, 119(1-2), 131-139.

Moradi M, Ershad D, Mirabou MA, Panahi B (2004) The role of plant debris, soil and manure on population density of Aspergillus flavus and Aspergillus niger groups in pistachio orchards of Kerman province. Iranian Journal of Plant Pathology. 40, 221-234. [In Persian]

Moradi M, Hokabadi H, Fani S (2015) A Study Concerned with the Factors Affecting the Fungal Growth and Aflatoxin Production During Storage of Pistachio in Kerman Province. Food Technology and Nutrient. (12), 83-92.

Pearce, N., Blair, A., Vineis, P., Ahrens, W., Andersen, A., Anto, J. M., … & Zahm, S. H. (2015). IARC monographs: 40 years of evaluating carcinogenic hazards to humans. Environmental health perspectives, 123(6), 507-514.

Shakerardekani A, Karim R, Mirdamadiha F (2012) The effect of sorting on aflatoxin reduction of pistachio nuts. Journal of Food, Agriculture and Environment. 10, 459-461.

Shakerardekani, A., Karim, R., & Mirdamadiha, F. (2012). The effect of sorting on aflatoxin reduction of pistachio nuts. J. Food Agric. Environ, 10(1), 459-461.

Shakerardekani, A., Karim, R., & Mirdamadiha, F. (2012). The effect of sorting on aflatoxin reduction of pistachio nuts. J. Food Agric. Environ, 10(1), 459-461.

Shamir, E., Megdal, S. B., Carrillo, C., Castro, C. L., Chang, H. I., Chief, K., … & Prietto, J. (2015). Climate change and water resources management in the Upper Santa Cruz River, Arizona. Journal of Hydrology, 521, 18-33.

Sherif, S. O., Salama, E. E., & Abdel-Wahhab, M. A. (2009). Mycotoxins and child health: The need for health risk assessment. International journal of hygiene and environmental health, 212(4), 347-368.

Turner, B. L., Kasperson, R. E., Matson, P. A., McCarthy, J. J., Corell, R. W., Christensen, L., … & Schiller, A. (2003). A framework for vulnerability analysis in sustainability science. Proceedings of the national academy of sciences, 100(14), 8074-8079.

Udomkun, P., Wiredu, A. N., Nagle, M., Müller, J., Vanlauwe, B., & Bandyopadhyay, R. (2017). Innovative technologies to manage aflatoxins in foods and feeds and the profitability of application–A review. Food control, 76, 127-138.

Wu, F., & Khlangwiset, P. (2010). Health economic impacts and cost-effectiveness of aflatoxin-reduction strategies in Africa: case studies in biocontrol and post-harvest interventions. Food additives and contaminants, 27(4), 496-509.

Wu, G., Bazer, F. W., Wallace, J. M., & Spencer, T. E. (2006). Board-invited review: intrauterine growth retardation: implications for the animal sciences. Journal of animal science, 84(9), 2316-2337.