Aflatoxin Contamination in Corn

Aflatoxin Contamination in Maize

Introduction

Aflatoxins are mycotoxins produced by two species of Aspergillus: A. flavus and A. parasiticus. These fungi are found especially in areas with hot and humid climates. Aspergillus flavus is reported to be able to survive at high temperatures (44-46°C), with optimum temperature for growth at 36-37°C; this fungus is able to produce aflatoxin with an optimal temperature of 25-27°C and a maximum of 42°C.

There are four main types of aflatoxins: B1, B2, G1 and G2. These four types of aflatoxin are separated depending on the color they develop in reaction to fluorescence under UV light (green or blue). The aflatoxins B1, B2, G1 and G2 from plants can be transported to milk, generating aflatoxins M1 and M2. Aflatoxin M1 represents a major metabolite of aflatoxin B1 in humans and animals, which may be present in milk from animals fed with aflatoxin B1 contaminated feed.

As aflatoxins are known to be genotoxic and carcinogenic, exposure through food should be kept as low as possible. After ingestion of aflatoxin, we can have acute toxicity with symptoms like food rejection, reduced weight gain, and abortion, or we can have cases of chronic toxicity with the development of liver cancer.

Aspergillus flavus, the key fungus for aflatoxin production, is well adapted to warm and dry weather conditions. Crops from tropical and/or sub-tropical areas are affected more frequently and severely by aflatoxin contamination, but temperate areas could be of increasing importance due to climate change. Aflatoxins are reported in several agricultural crops, mainly maize, peanuts, pistachio nuts and cotton seeds. We have decided to focus on maize contamination since this crop plays a main role both in food and feed supply worldwide.

Maize, after being introduced to the African continent in 1500, has become a staple food crop throughout Africa. It accounts for 30–50% of low-income household expenditures in East and Southern Africa, but it is also an important crop in West Africa, with Nigeria being one of the largest maize-producing nations on the continent. While maize serves as an important ingredient for the animal feed industry, humans consume 78% of the crop cultivated in Nigeria.

Causes of contamination

Aflatoxin contamination in maize may be caused by several species of Aspergillus section flavi. Contamination is strongly influenced by abiotic factors such as temperature and humidity: the contamination is greater in warm, humid conditions and even in hot deserts and drought conditions.

In general, the process of crop contamination with aflatoxins can be divided into two phases based on crop maturity. The first phase happens in the field during crop development and is associated with physical damage and plant stress; the second phase occurs after crop maturation until thegrain is ultimately consumed when the mature crop is exposed to environmental conditions favorable for aflatoxin-producing fungi (Probst & Cotty, 2012).

During the first phase of contamination, wounding of the crops by birds, mammals, and insects and the stress of hot, dry conditions results in significant infections. Climate can also directly influence host susceptibility (Cotty & Jaime-Garcia, 2007).

The second phase of contamination may occur at any time between crop maturation and consumption. It happens when the mature crop is exposed to warm, moist conditions in the field, or during storage or transportation. Under conditions of high humidity, initially, dry seeds can develop water content favorable for contamination. Substrate moisture content and temperature dictate the extent of contamination. When crops are exposed after maturation to conditions within these ranges, the second phase of contamination proceeds in the absence of either management intervention or highly effective microbial competitors (Cotty & Jaime-Garcia, 2007).

Impact of climate change

Until a few years ago, aflatoxins weren’t considered as a matter of concern for primary production in Europe; however, in recent years, this issue has become more relevant due to the detection of alarming contamination in maize, especially in South Europe.

Battilani et el.; conducted a study in order to predict A. flavus growth and aflatoxin production in maize, using weather data as input, two climate change scenarios (+2 °C and +5°C) were taken into consideration and to anticipate potential control options.

In the current climatic conditions, European countries in which maize cultivation is common (Romania, France, Hungary and north-east Italy) show a low probability of aflatoxin contamination. In the +2°C scenario, we can find an increase from a low to a medium probability of aflatoxin contamination, with critical aflatoxin contamination predicted some areas of southern European countries (Greece, southern Italy, Bulgaria and Albania), in which maize production is marginal, but important for the local population. In a +5 °C scenario, we will have a larger European area exposed to aflatoxin contamination. (Battilani, et al., 2015)

The future scenario of +2 °C hypothesized for Europe is the most realistic and could change several plant-pathogen interactions in the whole continent. In particular, due to climate change, aflatoxin contamination of maize kernels will be an important concern for food and feed safety and security.

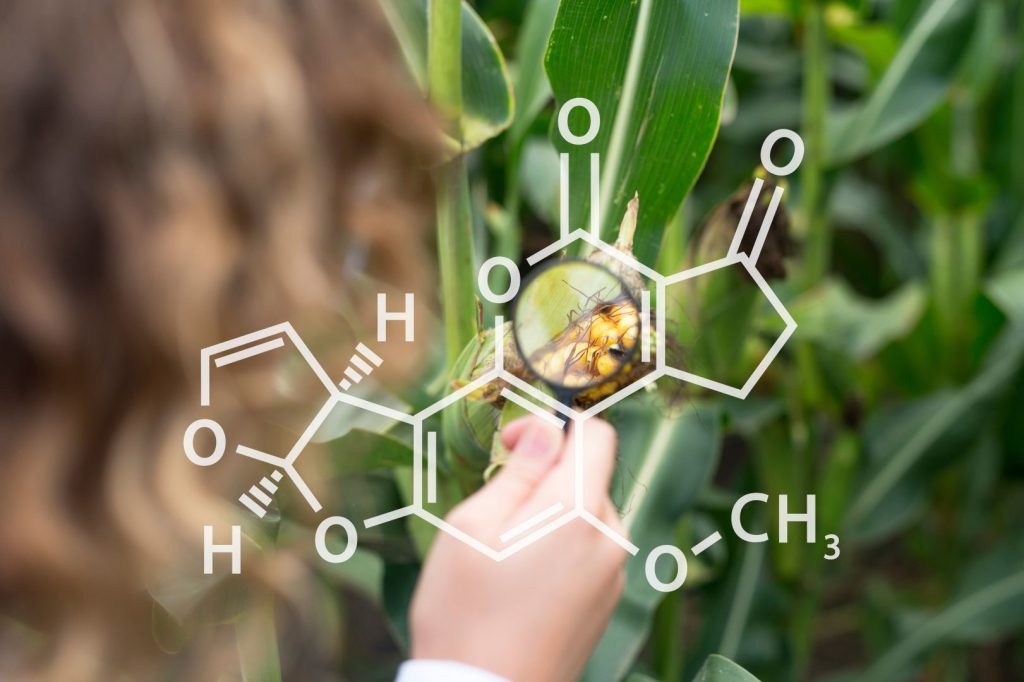

The chemical structure of aflatoxin

Damages

Impact of aflatoxin on maize trade/impact of aflatoxin contamination in the economy

Most economic impact analyses of aflatoxin have been conducted in the USA. Wu (2006) calculated the total costs of aflatoxins, estimating an annual loss of $163 million on average to US maize growers from aflatoxin. In other nations, Lubulwa and Davis (1994) estimated the annual

cost of aflatoxin in three countries (Philippines, Thailand, and Indonesia) to be nearly 1 billion USD per year due to a combination of market losses and livestock and poultry health losses. (Wu F., 2015)

In Africa, the economic impact of aflatoxins can be considered in the following issues:

- Trade-related impact: it determines is a product can be sold internationally

- firm-level impact in terms of costs of production to avoid aflatoxin contamination by prevention, control, or mitigation measures

- health impact leading to economic costs like the cost of illness (Meijer et al., 2021)

The annual economic loss of maize due to aflatoxin contamination was estimated to be in the hundreds of millions of dollars and has been predicted to reach as high as USD 1.68 billion due to global climate change, making aflatoxin contamination a serious economic threat to world trade of aflatoxin-susceptible crops. (Omolehin et al., 2021).

Impact on Human Health

Aflatoxins have been estimated to cause 25,000–155,000 liver cancer cases worldwide per year and to make up nearly a quarter of all liver cancer cases in high-exposure world regions, including Africa (Ademola, Turna, Liverpool-Tasie, Obadina, & Wu, 2021).

The most common aflatoxin, AFB1 is a genotoxin known to be carcinogenic and teratogenic for both humans and animals, it is also associated with serious health complications. AFB1 is a potent liver carcinogen, causing hepatocellular carcinoma (HCC) in humans and a variety of animal species. The International Agency for Research on Cancer (IARC) has classified “naturally occurring mixes of aflatoxins” as a Group 1 human carcinogen. (Wu, Stacy, & Kensler, 2013) Intake of low, daily doses of aflatoxins over long periods may lead to chronic aflatoxicosis expressed as impaired food conversion, stunted growth in children, immune suppression, cancer, and reduced life expectancy. Instead, ingestion of high concentrations of aflatoxin results in the rapid development of acute aflatoxicosis characterized by severe liver damage leading to jaundice, hepatitis, and, when most severe, death. (Probst, Schulthess, & Cotty, 2009)

Several studies have underlined how exposure to aflatoxins may cause adverse immune system effects and stunted growth in children. (Wu, Stacy, & Kensler, 2013). It has been demonstrated that concomitant exposure to aflatoxin and the hepatitis B virus (HBV) is common in developing countries and greatly increases HCC risk: individuals with both exposures often have a greater risk of developing HCC than those exposed to aflatoxin alone. (Wu, Stacy, & Kensler, 2013).

Regulations

The ingestion of aflatoxins from contaminated food and feed has led to serious health complications in humans and animals. Therefore, different countries have implemented strict regulations for aflatoxins in food and feed to maintain the health of individuals.

The safe limit of aflatoxins lies in the range of 4–30 μg/kg for human consumption. In Europe, the maximum levels for aflatoxins in food are set in Regulation (EC) 1881/2006 and subsequent amendments and it represents one of the strictest standard levels with AFB1 and total AFs not beyond 2 μg/kg and 4 μg/kg, respectively, in any product meant for direct consumption.

The maximum acceptable limit set for AFs in the United States is 20 μg/kg. (Mahato, et al., 2019). Aflatoxins have the highest acute and chronic toxicity of all mycotoxins; hence, the maximal concentration in agricultural food and feed products and their commodities is regulated worldwide. The possible change in patterns of aflatoxin occurrence in crops due to climate change is a matter of concern that may require anticipatory actions. (Battilani, et al., 2015).

Importance in Food processing

Fractionation is assumed to be the major cause of mycotoxin contamination that occurs during the primary processing of maize. Different steps, such as wet milling and dry milling, including various binding processes, possibly lead to chemical and biological changes in maize. The assessment of matrix-related toxins is, therefore a crucial step towards the risk analysis of mycotoxin contamination in maize products.

Dry Milling

It is believed aflatoxin contamination tends to vary among different tissues of maize after dry milling. For instance, the AFB1 levels were observed to be in reduced concentrations in the endosperm as compared to the whole kernel and bran fractions after the manual dehulling procedure. However, it has been noticed that clean and healthy maize kernels are more likely to reduce the aflatoxins levels significantly. Hence, the removal of broken kernels during the cleaning procedure leads to effective milling of maize and, thereby, reduces the contamination of aflatoxins to the desired level.

Wet Milling

Steeping or wet milling involves a further fractionation of maize kernels by a chemical process e.g., fermentation of kernels through the use of sulfur dioxide to aid the separation of starch from protein. Reduction of Aflatoxin levels seems to be directly proportional to the increased steeping time, steeping solution concentration, and temperature. According to Aly et al. 2011, the aflatoxin levels were much reduced in steeped kernels in comparison to unprocessed kernels. However, the washing of starch on the grain with water could possibly reduce the AFB1 concentrations further. In some studies, it is being proposed that the binding process during the fermentation might make it difficult to detect the aflatoxin levels in the liquid fractions as compared to bran, for instance (Schaarschmidt & Fauhl-Hassek, 2021).

An incidence of aflatoxin contamination in Malawian retail market

The first incidence of aflatoxin contamination in processed maize products in Malawi was reported in 2013. The collected samples of maize-based baby foods were found to be highly contaminated with aflatoxins, with concentrations exceeding the EU tolerance limit of 0.1 μg/kg fixed for baby products. All the local maize products were highly contaminated whereas the imported baby maize foods were free from aflatoxins contamination. It was then reported that highly contaminated raw maize was used in the local maize baby food. The maize-based puff snacks were, however, found to be contaminated with acceptable levels of aflatoxins with a limit of around 3 μg/kg (acceptable for human consumption). The reason for low contamination in puff snacks was assumed to be the use of dehulled maize flour in the snack preparation which usually contains less or no detected levels of aflatoxins (Matumba et al., 2014).

Aflatoxin Identification and Detection

Aflatoxins are the secondary metabolites that are carcinogenic in nature and are produced by two fungi, Aspergillus flavus and Aspergillus parasitic us. As those two fungal species are contaminants and are responsible for aflatoxin contamination of the food and feedstuff. The toxicity and potency make aflatoxin a hazard to health and a contaminant to processed food; therefore, the detection of aflatoxin is very important. (Alex P. Wacoo et al., 2014). Maize is susceptible to aflatoxin contamination and, therefore, is subject to sorting or other physical treatment before human consumption. The Maximum limits (μg/kg) of 5,0 ppb for Aflatoxin B1 and 10,0 ppb for the sum of Aflatoxins B1+B2+G1+G2. For maize and all products derived from maize, including processed maize products, maximum limits (μg/kg) of 2,0 ppb for Aflatoxin B1 and 4,0 ppb for the sum of Aflatoxins B1+B2+G1+G2 are set (European Feed Ingredients Safety Code, 3/6/2015).

Due to lower concentrations in foods, analytical methods for detection and quantification of aflatoxins must be specific, sensitive, and simple to carry out.

TLC, HPLC, ELISA, GC) and electrochemical immunosensors are being used widely. Each of these methods has advantages and limitations in aflatoxins analysis (Alex P at.al 2014).

Aflatoxins are generally soluble in polar protic solvents such as methanol, acetone, chloroform, and acetonitrile. Thus, the extraction of aflatoxins involves the use of these organic solvents, such as either methanol or acetonitrile or acetone mixed in different proportions with small amounts of water (T. Bertuzzi et al., 2012) and (S. L. Taylor at. Al. 1993).

Thin-Layer Chromatography (TLC): TLC lacks precision, and therefore to improve TLC has led to the development of an automated form of TLC called the high-performance thin-layer chromatography (HPTLC), which is one of the most efficient analytical methods. (J. Ramesh et.al, 2013).

High-Performance Liquid Chromatography (HPLC): Fast and accurate method, especially for G1 and B1 (P. Li, Q. Zhang, D. Zhang et al, 2011). A mobile phase comprising aqueous/organic solvents. Renton time is the standard for detection (Y. Xiang, Y. Liu, and M. L. Lee,2006). Programmable detectors such as either the fluorescent detector (FLD), the ultraviolet (UV) detector, or the diode array detector (DAD) may be used in the detection and identification of aflatoxins. To overcome the challenges associated with derivatization processes in aflatoxins analysis, a modification of the HPLC method, whereby the HPLC is coupled to mass spectroscopy (The HPLC-MS/MS) is used (M. Takino and T. Tanaka, 2008).

Spectroscopic Methods such as Fluorescence Spectrophotometry: Absorption in the ultraviolet-visible region is a very important procedure for unraveling the molecular structures of materials (D. Babu,2010). Due to detection limitation which is higher than 4 𝜇g/Kg set for European settings, this method is not used for products exported to Europe.

Frontier Infrared Spectroscopy (IR): Infrared spectroscopy relies on the alteration in molecular vibrations upon irradiation with infrared radiations.

Immunochemical Methods: Immunochemical techniques rely on the specificity of binding between antibodies and antigens; specific binding is not limited to antigens and antibodies.

Enzyme-Linked Immunosorbent Assay (ELISA): The potential health hazards related to the use of radioimmunoassay led to the lookout for a safer alternative and a suitable alternative to radioimmunoassay is to replace a radioactive signal with a nonradioactive one. This is achieved by labeling either the antigens or the antibodies with enzymes instead of isotopes 1969 (S. Avrameas, 1969).

Lateral Flow Devices (Immunodipsticks): immunochromatographic assays, also known as lateral flow devices. The principle is based on the use of high sensitivity and specificity of antibody-antigen reactions for the rapid detection of analytes (F. Ricci, G. Volpe, L. Micheli, and G. Palleschi, 2007). With respect to the type of signal transduction in use, immunosensors may be grouped into piezoelectric, optical, and electrochemical sensors (P. B. Luppa, L. J. Sokoll, and D. W. Chan, 2001). (1) Piezoelectric Quartz Crystal Microbalances (QCMs). are label-free devices used for direct detection of antigens. (2) Optical Immunosensors. A number of optical immunosensors have been developed for aflatoxins based on different transduction approaches. One of these optical immunosensors already developed for aflatoxin analysis is surface plasmon resonance (SPR).

The extraction of aflatoxins is usually followed by a cleanup step. To purify the sample, the cleanup technique used is immunoaffinity column (IAC) chromatography (F. Ma, R. Chen, 2013).

A short-wave infrared (SWIR) hyperspectral imaging system (1000–2500 nm) combined with chemometric data analysis is also used to detect aflatoxin B1 (AFB1) on surfaces of 600 kernels in the USA (Georgia, Illinois, Indiana and Nebraska). SWIR spectra combined with chemometrics and spectra pretreatments showed the possibility of detecting maize kernels of different varieties coated with AFB1. The detection accuracy is linked to the increased constituents (lipids, Protein, starch and water) of the kernel (Daniel Kimuli et.al, 2005). Chemometrics are found effective in finding the chemical differences between samples and minimizing variation due to physical effects. (Daniel Kimuli et. al, 2005).

Food Safety and Aflatoxin

Aflatoxins are responsible for damaging up to 25% of the world’s food crops, resulting in large economic losses in developed countries and human and animal disease in underdeveloped ones. (Hamed K. 2019). Mycotoxins pose a significant threat to the safety of food and its products. (Marco Camardo Leggieri et.al, 2021). Aflatoxins are a common contaminant of cereals that can cause cancer, liver disease, immune suppression, retarded growth and development, and death, depending on the level and duration of exposure. Maize is an introduced crop to Africa and there have been efforts over the last 20 years or so to replace traditional cereal crops, such as sorghum (Sorghum bicolor) and pearl millet (Pennisetum glaucum), with maize. Maize is significantly more heavily colonized by aflatoxin-producing Aspergillus spp. than either sorghum or millet. European Food Safety Authority (EFSA) has assessed the risks of dietary exposure to mycotoxins for public health and for the health of farm and companion animals on the request of the European Commission and has assessed the safety and efficacy of feed additives for the reduction of contamination of feed by mycotoxins within the European Union authorization process for feed additives. Mycotoxins belong to one of the important areas of the EFSA work. Occurrence data on mycotoxins submitted to EFSA by the European national food safety bodies. AF could pass through metabolic processes in unaltered forms and consequently accumulate in the tissues of humans and animals. Practical applications Cereal and cereal-based products can be considered as one of the most important sources of food as well as energy in many countries. The adverse effects of contamination by mycotoxins on food safety and food quality are of great concern (Amin Mousavi Khaneghah et.al, July 2018). Maize is domestically grown in Malawi and is a single source of calories and a contributor to the economy. The climate of Malawi is projected to get warmer (by 1–2.5°C) and drier. These climate changes are projected to make the pre-harvest conditions for Malawian maize more favorable for AFB1 contamination. (Erika A. Warnatzsch et.al, 2020) The increase in aflatoxin levels during multi-month postharvest storage is a serious health hazard affecting several major crops. During postharvest crop storage by conventional methods in tropical conditions, molds existing within crops can produce aflatoxin levels many times greater than at harvest, often vastly exceeding the international safety standards of 20 ppb (parts per billion). For example, field data from Mali documents that during just two months of conventional peanut storage, average aflatoxin levels rose 200%. In Uganda, aflatoxin levels in conventionally stored maize rose 300% in three months. By contrast, laboratory and field data from Mali and Uganda show that the organically modified atmosphere created using various forms of sufficiently hermetic (airtight) storage containers (ranging from 25kg to 1000-tonne capacity) prevents the exponential growth of aflatoxin-producing molds in various grains, peanuts, and seeds ( Philippe Villers et.al, 2017).

Prevention and Control

Pre-harvest AFB1 contamination in maize

Mahuku et al., in 2019, tested various maize samples obtained from smallholder farmers’ fields and identified exceeded aflatoxin levels that pose threat to the public’s health. Matured maize samples collected from the fields in south-western and eastern Kenya showed an equal incidence of contamination. However, the level of contamination was relatively higher in the samples obtained from Eastern Kenya. It is believed that the higher level of aflatoxins found in Maize fields from eastern Kenya was probably due to the harsh climatic conditions with higher temperatures and drought. Moreover, the presence of the S-morphotype strain of Aspergillus flavus is believed to have a negative impact on maize fields in the eastern region of Kenya. The occurrence of aflatoxin contamination in the maize collected from storage revealed the highest possibility of AFB1 contamination in the mature maize (pre-harvest) in the field. It is important to note that both local and hybrid maize varieties used in the experiment showed equal AFB1 contamination. It is suggested that the currently used maize germplasm is inefficient in controlling the A.flavus infection along with aflatoxin contamination. The study highlights the need to develop heat- and drought-resistant maize varieties that are more suitable to Kenya’s diverse agro-ecological climate.

Post-harvest management practices

The use of mobile maize dryers and hermetic bags (for storage), including plastic sheets, was practiced in a randomized controlled trial by Pretari et al., 2019 in the rural area of Kenya. The trial included the small-holder farmers of the region who have previously used different drying and storage techniques e.g., the maize was stored in the houses and dried on bare earth or sometimes under the sun. The intensive training sessions were provided to the farmers to educate them about the post-harvest management strategies to avoid aflatoxin contamination in the maize crop. The criteria for the hermetic bag distribution were based on the presence of maize moisture content above 13.5%. When compared to the control group, the maize dried from the mobile dryer contained 78% less AFB1 contamination levels. These storage and drying practices allowed the small-scale farmers to store their harvested maize for a longer period of time thereby improving their socio-economic conditions. Moreover, the overall incidence of pests and mold infestations was reduced in maize crops through the use of proper drying services along with hermetic bags.

Solutions & Future Perspective

Biocontrol strategy

As mentioned above, the pre-harvest maize crop is the primary source of aflatoxin contamination that has been observed so far. The conducted trials on the maize crops reveal the need to develop a strategy that can control the maize AFB1 contaminations at the pre-harvest stage (matured maize). Among many integrated techniques, the bio-control strategy to control AFB1 in maize could be termed the most sustainable solution to control the contamination of aflatoxins in maize. Although biological control techniques are being practiced in-vitro already, the need to implement these techniques commercially in the field is a challenge to face. Agbetiameh et al. in 2020, successfully tested the atoxigenic strain of Aspergillus flavus against aflatoxin contamination (maize) in Italy. The contaminated maize crop that was inoculated with atoxigenic strain of A.flavus, resulted in the displacement of aflatoxins by the uniform distribution of these biocontrol agents (strains). The incidence of AFB1 reduction recorded in the treated maize crop was about 93%. Therefore, the bioactive ingredient was selected as the biocontrol agent for the commercial use.

Mycotoxin inhibition through lactic acid fermentation

Ogi is a popular and affordable maize-based product consumed widely across Nigeria for breakfast. Ogi production includes a natural process of fermentation caused by the presence of microorganisms in the environment; the dominant species in the fermentation process is LAB. Various studies have examined the level of aflatoxin after processing and fermentation of this maize-based product: the mean total aflatoxin level in the final product is typically close to the maximum acceptable limit shared by Nigeria and the European Union: 4 μg/kg. Processing through lactic acid fermentation has, therefore shown to significantly reduce levels of aflatoxins in maize products. As ogi is a common weaning food for Nigerian children, the fermentation process used to produce it is potentially beneficial in reducing mycotoxin-related health risks in a sensitive population. Although these studies indicate that LAB fermentation can reduce mycotoxin levels in ogi, the mechanism of how these toxins are reduced during fermentation is not well understood yet (Ademola, Turna, Liverpool-Tasie, Obadina, & Wu, 2021).

Aflatoxin inhibition through plant extract

The control of A. Flavus in grains and food during storage is essential for food safety; however, synthetic antioxidants can be harmful, whereas plant extracts have great potential, as they are active, easy to prepare and apply, and easy to biodegrade. Globally, fruit peels are considered agricultural waste, and they cause waste management problems despite containing many materials

with biological activities. For example, tannins, alkaloids, flavonoids, terpenoids, and glycosides are bioactive compounds that are usually available in the peel of bananas, doum, and licorice.

In this study, the licorice, doum, and banana plant peels were extracted with different solvents like ethanol, acetone, methanol, and diethyl ether at concentrations of 25, 50, and 75%, to study their effect on A. flavus growth (dry and wet weight) and AFB1 production.

Most of the tested solvents at different concentrations were highly effective against AFB1 production. Efficiency ratios of AFB1 inhibition (ER%) values ranged from 34 to 91%. Among four solvent extracts of licorice, doum, and banana peels, the 75% licorice diethyl ether extract was intensely active, showing the best wet and dry weight inhibition of maize aflatoxigenic fungus, Aspergillus flavus; it also exhibited the highest efficacy ratio (91%). Regarding aflatoxin B1 production, all the tested plant extracts were effective against AFB1 production after one month of maize storage, with average efficacy ratios ranging from 74.1% to 97.5% compared with Thiram fungicide (20.1%).

The mode of action of these plant extract antioxidants suppresses aflatoxins by neutralizing and scavenging free radicals and inhibiting their chains of propagation, rendering them into less toxic molecules.

These plant extracts represent a great way to restore value to these by-products by using them against aflatoxin production. (Youssef, et al., 2021)

Use of Electronic nose (e-nose) for AFB1 detection

A very rapid detection method in the maize samples. This technique can be used with the HPLC- MS using a conventional method. (HPLC-MS) and a portable e-nose “AIR PEN 3” (Airsense Analytics GmbH, Schwerin, Germany) equipped with a 10-metal oxide sensor array. Artificial neural network (ANN), logistic regression (LR), and discriminant analysis (DA) are used to investigate whether the e-nose was capable of separating samples contaminated at levels above or below the legal limits. This gives 78% and 77% accuracy for AFB1 and FBs, respectively (Gobbi, Falasconi, Torelli, & Sberveglieri, 2011). The e-nose is equipped with pattern recognition software for data recording and processing (WinMuster, v. 1.6.2.13).

Host Induced Gene Silencing (HIGS) for AFB1 reduction

Omolehin et al., in 2021, demonstrated the efficiency of Host Induced Gene Silencing (HIGS) in suppressing host-induced infection by various pathogenic fungi. The principle of this technique is to change the chemical and genetic structure of the aflatoxin. The alkaline protease of A. flavus gene is focused for silencing through HIGS, as an RNAi vector carrying a portion of the alk gene is incorporated into maize genome labeled as B104. The log of 4 out of 8 gene sequencing was self-pollinated to T4/T6 generations, and the transgenic varieties showed around 87% aflatoxin reduction. The reduced level of fungal DNA in the transgenic maize proposed the successful resistance of maize kernels to the infection. The alkaline protease of A. flavus gene is focused on silencing.

Further Reading

Aflatoxin Contamination of Pistachio nuts

Contaminant Detection: Tools for Ensuring Food Safety

References

Agbetiameh, D., Ortega-Beltran, A., Awuah, R. T., Atehnkeng, J., Elzein, A., Cotty, P. J., & Bandyopadhyay, R. (2020). Field efficacy of two atoxigenic biocontrol products for mitigation of aflatoxin contamination in maize and groundnut in Ghana. Biological Control, 150(May), 104351.

Mahuku, G., Nzioki, H. S., Mutegi, C., Kanampiu, F., Narrod, C., & Makumbi, D. (2019). Pre- harvest management is a critical practice for minimizing aflatoxin contamination of maize. Food Control, 96(June 2018), 219–226.

Matumba, L., Monjerezi, M., Biswick, T., Mwatseteza, J., Makumba, W., Kamangira, D., & Mtukuso, A. (2014). A survey of the incidence and level of aflatoxin contamination in a range of locally and imported processed foods on Malawian retail market. Food Control, 39(1), 87–91.

Omolehin, O., Raruang, Y., Hu, D., Han, Z.-Q., Wei, Q., Wang, K., Rajasekaran, K., Cary, J. W., & Chen, Z.-Y. (2021). Resistance to Aflatoxin Accumulation in Maize Mediated by Host- Induced Silencing of the Aspergillus flavus Alkaline Protease (alk) Gene. Journal of Fungi, 7(11), 904.

Pretari, A., Hoffmann, V., & Tian, L. (2019). Post-harvest practices for aflatoxin control: Evidence from Kenya. Journal of Stored Products Research, 82(June 2013), 31–39.

Schaarschmidt, S., & Fauhl-Hassek, C. (2021). The fate of mycotoxins during the primary food processing of maize. In Food Control (Vol. 121). Elsevier Ltd.

Ademola, O., Turna, N., Liverpool-Tasie, L., Obadina, A., & Wu, F. (2021). Mycotoxin reduction through lactic acid fermentation: evidence from commercial ogi processors in southwest Nigeria. Food Control.

Battilani, P., Toscano, P., Van der Fels-Kler, H. J., Moretti, A., Camardo Leggieri, M., Brera, C.,. . . Robinson, T. (2015). Aflatoxin B1 contamination in maize in Europe increases due to climate change. Scientific Reports.

Cotty, P. J., & Jaime-Garcia, R. (2007). Influences of clmate on aflatoxin producing fungi and aflatoxin contamination. International Journal of Food Microbiology.

Mahato, D. K., Lee, K. E., Kamle, M., Devi, S., Dewangan, K. N., Kumar, P., & Kang, S. S. (2019). Aflatoxin in Food and Feed: an overview on Prevalence, Detection and Control Strategies. Frontiers in Microbiology.

Meijer, N., Kleter, G., De Nijis, M., Rau, M.-L., Derkx, R., & Van Der Fels-Klerx, H. (2021). The aflatoxin situation in Africa: systematic literature review. Comprehensive reviews in food science and food safety.

Probst, C., & Cotty, P. J. (2012). Relationships between in vivo and in vitro aflatoxin production: reliable prediction of fungal ability to contaminate maize with aflatoxins. British Mycological Society.

Probst, C., Schulthess, F., & Cotty, P. (2009). Impact of Aspergillus section Flavi community structure on the development of lethal levels of aflatoxins in Kenyan maize (Zea mays). Journal of Applied Microbiology.

Wu, F. (2015). Global impact of aflatoxin in maize: trade and human health. World Mycotoxin journal.

Wu, F., Stacy, S. L., & Kensler, T. W. (2013). Global Risk Assessment of Aflatoxins in Maize and Peanuts: Are Regulatory Standards Adequately Protective? Toxicological Sciences. Youssef, N. H., Hari, S., Matar, S., Hamad, A., Dessoky, E., Elshaer, M., . . . Behiry, S. (2021).

Licorice, doum, and banana peel extracts inhibit Aspergillus Flavus growth and suppress metabolic pathway of Aflatoxin B1 production. Agonomy. Abbas, H. K. (Ed.). (2005). Aflatoxin and food safety. Crc Press.

Kimuli, D., Wang, W., Jiang, H., Zhao, X., & Chu, X. (2018). Application of SWIR hyperspectral imaging and chemometrics for identification of aflatoxin B1 contaminated maize kernels. Infrared Physics & Technology, 89, 351-362.

Bertuzzi, T., Rastelli, S., Mulazzi, A., & Pietri, A. (2012). Evaluation and improvement of extraction methods for the analysis of aflatoxins B 1, B 2, G 1 and G 2 from naturally contaminated maize. Food analytical methods, 5(3), 512-519.

Taylor, S. L., King, J. W., Richard, J. L., & Greer, J. I. (1993). Analytical-scale supercritical fluid extraction of aflatoxin B1 from field-inoculated corn. Journal of Agricultural and Food Chemistry, 41(6), 910-913.

FISC- Code of good practice for the monitoring of B1 in maize- version 1.1-European Feed Ingredients Safety Code Code of good practice for the monitoring of Aflatoxin B1 in maize and maize co- products (feed materials) derived thereof. 3.06.2015.

Mousavi Khaneghah, A., Eş, I., Raeisi, S., & Fakhri, Y. (2018). Aflatoxins in cereals: State of the art. Journal of food safety, 38(6), e12532.

Wacoo, A. P., Wendiro, D., Vuzi, P. C., & Hawumba, J. F. (2014). Methods for detection of aflatoxins in agricultural food crops. Journal of applied chemistry, 2014(1-15), 706291. Leggieri, M. C., Mazzoni, M., Fodil, S., Moschini, M., Bertuzzi, T., Prandini, A., & Battilani, P. (2021). An electronic nose supported by an artificial neural network for the rapid detection of aflatoxin B1 and fumonisins in maize. Food Control, 123, 107722.

Bandyopadhyay, R., Kumar, M., & Leslie, J. F. (2007). Relative severity of aflatoxin contamination of cereal crops in West Africa. Food additives and contaminants, 24(10), 1109-1114.

Eskola, M., Altieri, A., & Galobart, J. (2018). Overview of the activities of the European Food Safety Authority on mycotoxins in food and feed. World Mycotoxin Journal, 11(2), 277- 289.

Villers, P. (2017). Food safety and aflatoxin control. Journal of Food Research, 6(2), 1-12.